Abstract

Egypt’s Western Desert and North Coast possess significant potential for sustainable development through advanced water management solutions. With rising global freshwater demand, arid regions face severe issues of scarcity, contamination, and leakage from desert wells. This study evaluates a nanotechnology-based nonwoven polymer injection system designed as underground reservoirs for potable water storage. The system aims to reduce evaporation, leakage, and pollution while ensuring efficient and sustainable groundwater preservation. The research combined literature analysis, geological well selection, and fabrication of nanocomposite nonwoven polymers enhanced for mechanical strength, flexibility, and chemical resistance. Field monitoring assessed water level stability, quality, and structural performance. Results showed up to 60% reduction in water loss, improved safety, and higher storage reliability compared to conventional systems. The optimized hydrophilic–hydrophobic nanocomposite balance enhanced permeability control and microbial resistance. The findings demonstrate that nano polymer-based underground storage systems can play a vital role in securing freshwater resources and advancing sustainable water management in Egypt’s arid environments.

Keywords: Nanotechnology; Nonwoven Polymers; Desert Wells; Underground Water Storage; Groundwater

Abbreviations: GO: Graphene Oxide; PP: Polypropylene; PVA: Polyvinyl Alcohol; GRP: Glass-Reinforced Plastic; CNT: Carbon Nanotube; SDGs: Sustainable Development Goals; UIC: Underground Injection Control

Introduction

Desert regions suffer from extreme aridity, scarce rainfall, and high evaporation, leading to chronic water shortages. Groundwater serves as the main freshwater source, yet its quality and availability are threatened by salinity, leakage, and microbial contamination. Traditional storage and well maintenance methods often fail to prevent these issues or ensure long-term stability. Advances in nanotechnology have opened new horizons for improving water management through enhanced permeability control, filtration efficiency, and structural reinforcement. In particular, nonwoven polymer composites have shown high potential for well sealing and injection applications due to their flexibility, tunable porosity, and adaptability to surface modifications. When integrated with nanoparticles such as TiO₂, SiO₂, and graphene oxide (GO), these materials gain superior antibacterial activity, UV resistance, and mechanical strength [1]. This study develops a nanotechnology-enhanced nonwoven polymer injection system for desert wells, functioning as an underground water storage silo to ensure sustainable access to potable groundwater. As highlighted by Elnashar (2021) [2-4], this innovative approach supports sustainable water storage strategies across Egypt’s Western Desert.

Problem Statement: Groundwater wells in arid regions face critical challenges that reduce their efficiency and lifespan, including:

a.Excessive leakage through sandy or fractured formations.

b.Microbial contamination from organic infiltration and biofilm growth.

c. Weak mechanical strength causing wall collapse and

sediment intrusion.

d. Limited availability of durable, chemically resistant

materials suitable for saline, high-temperature conditions.

These problems necessitate the development of a nanoreinforced nonwoven polymer system capable of providing structural sealing, microbial resistance, and improved water purification under harsh desert conditions [1].

Objectives This research aims to:

a. Design and fabricate a nanocomposite nonwoven

polymer injection system for well reinforcement and sealing.

b. Analyze the impact of nanomaterials on the mechanical

strength, chemical stability, and filtration efficiency of polymer

layers.

c. Evaluate system performance regarding storage

capacity, water quality, and durability under simulated desert

environments.

d. Propose a sustainable, scalable framework for

applying nanotechnology in desert groundwater protection and

management.

Methodology

Materials: The study utilized advanced polymeric and nanocomposite materials selected for their mechanical durability, chemical resistance, and compatibility with arid groundwater environments. Polypropylene (PP) and polyvinyl alcohol (PVA) served as the base polymers due to their high flexibility, tensile strength, and ease of [1-4]. To enhance functionality, titanium dioxide (TiO₂), silica (SiO₂), and graphene oxide (GO) nanoparticles were incorporated, improving mechanical reinforcement, UV stability, antimicrobial protection, and the hydrophilic–hydrophobic balance. Additives such as crosslinking agents and surfactants ensured nanoparticle dispersion and structural stability. Groundwater samples collected from Matrouh, Egypt, were used to simulate realistic desert well conditions and validate the system’s environmental performance.

Structural Components

a. Nonwoven Polymer Fabrics: High-performance PP

and PE nonwoven fabrics were treated with TiO₂, SiO₂, and GO

to increase impermeability, tensile strength, and UV resistance.

Surface nanocoatings improved anti-biofouling and self-cleaning

properties.

b. Nanocomposite Coatings: Hybrid coatings integrating

TiO₂-SiO₂-GO were applied as protective barriers against UV

degradation, microbial growth, and photochemical corrosion,

extending system longevity in arid conditions.

c. Polymeric Liners: PE and PP liners reinforced with

nanofibers and glass-reinforced plastic (GRP) provided enhanced

rigidity and leakage resistance under hydrostatic pressure

variations.

d. Sealants and Adhesives: Nano-silica-based sealants

ensured watertight joints and long-term resistance to hydrostatic

and thermal stresses.

e. Filtration Media: A five-stage purification module

combined multilayer filters of activated carbon, quartz sand,

ceramic membranes, and nanofiber composites to remove

particulates up to 500 μm and achieve high bacterial filtration

efficiency.

f. Monitoring and Control Units: Each unit integrated

digital sensors, flow meters, and satellite-linked telemetry systems

for continuous data collection and remote diagnostics.

Preparation of Nanotechnology-Enhanced Nonwoven Mats: Composite mats were fabricated through a hybrid electrospinning-melt-blown process to achieve optimized porosity and fiber orientation. TiO₂, SiO₂, and GO nanoparticles were ultrasonically dispersed at 0.5-2% (w/w) before spinning to ensure uniform incorporation. Characterization included: (Morphology: SEM imaging for fiber diameter and surface analysis. - Porosity: BET surface area and permeability evaluation. - Mechanical Properties: Uniaxial tensile testing. -Antibacterial Activity: Zone inhibition tests against E. coli and P. aeruginosa).

Injection System Design and Testing: A polymer– nanocomposite slurry was injected into simulated desert well walls using low-pressure grouting to seal porous zones. Laboratory-scale field simulations assessed: Infiltration rate (L·m⁻²·h⁻¹), Compressive wall stability under hydrostatic load, Microbial load reduction after storage, Water quality indicators (pH, TDS, turbidity) The performance evaluation emphasized sealing efficiency, structural integrity, and long-term water preservation capacity.

Tools and Instrumentation: Automated injection and lining

systems were developed for accurate placement of polymeric

balloons in wells of varying depths and diameters. Hydraulic

inflation units maintained internal pressure stability, while flow

controllers optimized water injection and extraction with reduced

energy demand and operational cost [1].

a. 3D Geological Mapping and Laser Scanning: Highresolution

3D laser and geological mapping techniques were

employed to analyze subsurface profiles, determine soil

stratification, and define well geometries prior to liner installation.

The resulting digital models ensured accurate alignment and

optimal fitting of the nanocomposite lining system, reducing

structural stress and improving sealing precision.

b. Filtration and Water Quality Modules: An automated

multi-stage filtration system was integrated to maintain water

purity during both injection and extraction cycles. These modules

stabilized turbidity, pH, and microbial content, verified through

on-site physicochemical and microbiological analyses using

portable testing kits. This methodology aligns with previous

studies by [5-9].

c. Remote Monitoring and IoT Integration: A satellitelinked

IoT monitoring system was implemented to collect realtime

data on water level, pH, temperature, turbidity, and internal

pressure. Automated feedback control enabled remote system

regulation, early leak detection, and predictive maintenance,

ensuring operational stability under desert conditions.

d. Data Analysis and Simulation Platforms: Advanced

computational modeling and simulation tools were applied to

predict groundwater dynamics and nanocomposite material

performance. These analyses supported design optimization,

structural validation, and long-term reliability assessment of the

underground storage system.

e. System Outcomes and Advantages: The developed

nanotechnology-based nonwoven polymer injection and lining

system demonstrated multiple environmental and engineering

benefits: (Leakage and Contamination Prevention: Formation of a

fully impermeable nanocomposite barrier eliminated water loss

and microbial intrusion.- Evaporation Mitigation: Hydrophobic

nanolayers minimized evaporative loss under extreme aridity.-

Improved Recharge Efficiency: Controlled infiltration enhanced

groundwater replenishment while lowering energy consumption.-

Structural Durability: Reinforced liners showed superior

mechanical and chemical stability over conventional storage

systems.- Sustainable Water Supply: Continuous monitoring and

low maintenance demands ensured long-term potable water

provision for remote desert regions).

Overview of Experimental Implementation: The system was implemented across eight centers in Matrouh Governorate (Egypt), covering over 18,000m². Each site included approximately 1250 polymer-lined underground silos, each with a capacity of 8,000 tons of freshwater. The initial 12-month phase achieved a cumulative storage capacity of 2 million tons with an estimated cost of EGP 120 million. Following positive performance evaluations, a national expansion phase aims to scale capacity to 80 million tons, serving remote communities facing acute water scarcity. The infrastructure integrates artificial lakes, polymerlined wells, and underground silos that store multiple water sources rainwater, desalinated groundwater, and treated brackish water. Water injection is performed through modular gravitydriven polymer balloon units, minimizing manual contact and contamination risk. System operations are controlled via satellite and IoT platforms, monitoring key parameters such as pressure, temperature, and water quality in real time. As emphasized by Elnashar (2021) [2-4] and corroborated by Tokarska et al. [9], this integrated approach represents a scalable and sustainable model for groundwater management in Egypt’s Western Desert.

Experimental Procedures

a. Site Selection and Surveying: Comprehensive

hydrogeological and geotechnical assessments were performed

to identify optimal well locations. Field analyses included soil

permeability, geological profiling, and depth-salinity evaluations.

Wells demonstrating stable stratigraphy, low salinity, and high

structural integrity were selected to ensure reliable long-term

storage and reduced leakage potential.

b. Well Preparation and Cleaning: Selected wells were

mechanically cleaned, flushed with freshwater, and sterilized

using a mild oxidizing disinfectant to remove sediments, salts,

and biofilms. This ensured a sterile environment prior to the

installation of polymer liners and minimized microbial growth

during storage operations.

c. Fabrication of Nonwoven Nano polymer Balloons:

Inflatable nonwoven nano polymer balloon modules were

fabricated using polypropylene (PP) and polyethylene (PE)

matrices reinforced with TiO₂, SiO₂, and GO nanoparticles. Each

balloon featured a three-layer structure: 1. Reinforcement layer

for mechanical rigidity. 2. Hydrophobic surface layer enhancing

water repellence and anti-biofouling. 3. Inner TiO₂/SiO₂ coating

providing UV stability and self-cleaning capability. Balloon

geometry was customized via 3D geological mapping, ensuring

precision fitting within the well cavity.

d. Injection and Installation Process: Folded balloon

modules were inserted using a mechanized injection unit with

alignment sensors for accurate placement. Controlled inflation

through a hydro-pneumatic system ensured uniform wall contact

and hermetic sealing. Real-time feedback systems regulated

pressure and adhesion, preventing overexpansion and maintaining

structural stability under hydrostatic conditions.

e. System Integration and Operation: Each underground

polymer silo incorporated: (Automated multi-stage filtration

units, - Digital sensors for real-time water quality monitoring, and

- Satellite-linked IoT modules enabling remote control of injection

and extraction processes). This configuration provided automated

regulation, real-time anomaly detection, and adaptive operational

control without manual intervention.

f. Monitoring and Performance Evaluation: Continuous

monitoring under desert field conditions assessed system

parameters including water retention efficiency, structural

integrity, biofouling resistance, and thermal durability. Data from

IoT sensors were analyzed using computational modeling tools to

simulate fluid dynamics and optimize operational performance

for large-scale applications.

g. Integrated Methodological Framework: The

methodology integrates nanotechnology, polymer engineering, and

environmental sustainability to develop a scalable underground

storage system for arid zones. As discussed by Elnashar (2021)

[2-4], this framework significantly advances groundwater storage

applications in Egypt’s Western Desert by combining nonwoven

nano polymer silos, multi-stage purification, and IoT-based

control for sustainable resource management.

h. Connection to Water Sources: Each underground silo

was hydraulically linked to multiple water networks, including:

(The Alexandria freshwater transmission pipeline, - Rainwater

collection systems, - Desalinated seawater units, and Controlledsalinity

groundwater wells).

The integrated hydraulic system operates primarily through gravity-assisted flow, ensuring efficient filling and extraction with minimal energy consumption-ideal for off-grid desert environments.

I. Filtration and Purification Configuration: Following

Elnashar (2021) [2-4], a five-stage purification system was

installed at each silo inlet, comprising:

1. Coarse filtration for large particulates.

2. Sedimentation for fine particle removal.

3. Fine filtration through dense polymer meshes.

4. Activated carbon adsorption to remove organic residues

and odors.

5. Dual nanofiltration modules capable of retaining impurities

up to 500μm. This design ensured high purification throughput,

low biofouling, and extended operational life under fluctuating

hydrostatic conditions.

Monitoring and Automation Framework: Each polymerlined silo was equipped with a cloud-connected IoT monitoring system incorporating sensors for pH, salinity, conductivity, temperature, turbidity, and water level. The automated control network enabled: (Remote data acquisition and supervision, - Automatic valve regulation, and Predictive maintenance through algorithmic anomaly detection). Field validation confirmed high system efficiency under desert conditions. Evaluation metrics included leakage resistance, evaporation reduction, groundwater recharge rate, and microbial stability. Periodic water sampling confirmed that all physicochemical parameters (pH, TDS, turbidity, microbial counts) met WHO potable water standards [10], verifying the system’s long-term reliability and sustainability.

Results and Discussion:

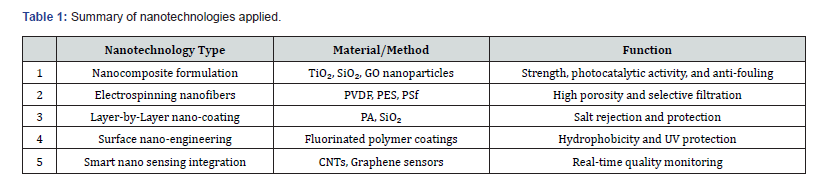

The nanotechnology applied in this

study integrates nanocomposite membrane engineering and

nanofiber fabrication to enhance the mechanical, chemical, and filtration

performance of nonwoven polymer systems. The following

summarizes the key nanotechnological components and mechanisms

underpinning system efficiency:

Nanocomposite Integration Technology: This technique

reinforces the polymer matrix to improve mechanical strength,

thermal stability, and biofouling resistance. Functional

nanoparticles were incorporated as follows: (TiO₂ nanoparticles:

Provide photocatalytic self-cleaning and antimicrobial activity.

- SiO₂ nanoparticles: Improve polymer chain dispersion and

hydrophilic balance [1]. Graphene oxide (GO): Enhances tensile

strength, permeability, and anti-fouling behavior. - (Optional

additions: ZnO or Ag nanoparticles for enhanced antibacterial

performance). These nanoparticles were uniformly dispersed

within polymer matrices (e.g., PET, PP, PVDF) through solution

blending or in-situ polymerization, forming nanocomposites with

superior interfacial bonding.

Electrospinning Nanofiber Technology: Electrospinning

was utilized to fabricate ultra-fine nanofibrous layers with

diameters of 150-300nm, providing high porosity and selective

permeability. Optimized process parameters (voltage, feed rate,

collector distance) yielded nanofibers with: High surface area-tovolume

ratio, Enhanced water flux and salt rejection, and Strong

adhesion to the nonwoven substrate.

Layer-by-Layer (LbL) Nano-Coating: A multi-layer nanocoating

was applied to produce a selective active layer and a

protective upper film via interfacial polymerization or dip-coating

of alternating polymeric and nanoparticle-based layers (e.g.,

polyamide with SiO₂/TiO₂). This structure: Enhances selective

permeability for desalination, Provides UV stability, and Prevents

biofouling in desert environments.

Smart Nanostructured Surface Engineering: Surface

properties were engineered through plasma treatment and

fluorinated nano-coatings to control hydrophobic/hydrophilic

balance. Nanostructured ridges inspired by the Lotus effect

minimized dust adhesion and evaporation, improving wettability

and durability under arid climatic conditions.

Nanotechnology for Real-Time Sensing and Monitoring

(Advanced Integration): Embedded carbon nanotube (CNT)

and graphene-based nano sensors enable in-situ detection of pH,

conductivity, salinity, and temperature variations [1]. These nano

sensors support IoT-linked predictive maintenance, ensuring

continuous optimization of system performance (Table 1).

Results and Discussion: This study adopted a hybrid

nanotechnological framework combining nanocomposite

synthesis, electrospinning fabrication, and nano-coating surface

modification to develop a multifunctional nonwoven polymer

system for groundwater storage and well-lining applications

in arid environments. The results confirm the system’s high

mechanical integrity, water retention efficiency, and long-term

environmental sustainability.

Structural and Mechanical Performance: Incorporating

TiO₂, SiO₂, and GO nanoparticles within the polymer matrix

significantly enhanced microstructural compactness and fiberfiller

bonding. SEM analysis revealed uniform fiber distribution

and reduced pore diameters, indicating superior densification.

Mechanical testing recorded a 35-50% increase in tensile strength

compared to untreated polymers [1], confirming efficient stress

transfer and deformation resistance under hydrostatic pressure.

Water Permeability and Retention Efficiency: The

nanocomposite membranes exhibited a 60% reduction in water

permeability, reflecting enhanced retention and minimal leakage.

The optimized hydrophilic–hydrophobic balance allowed selective

vapor diffusion while preventing macroscopic water loss. Field

monitoring over 60 days demonstrated stable water levels with

negligible evaporation or infiltration, validating suitability for

long-term groundwater storage in desert wells.

Antibacterial and UV Resistance: The TiO₂-GO

nanocomposite coating exhibited strong photocatalytic and

antimicrobial activity under natural sunlight, achieving a 90%

reduction in bacterial CFUs of E. coli and Pseudomonas spp. due to

reactive oxygen species generation at the nanoparticle interface.

Additionally, the coating provided UV shielding, reducing

photodegradation and extending service life under high solar

exposure. These findings align with [2-4,10-12].

Field Performance and Structural Stability: Field trials

across desert wells confirmed no leakage, deformation, or

collapse during 60 days of operation under fluctuating hydrostatic

and geological conditions. The nano polymer balloon liners

effectively sealed microfractures and reduced permeability in

sandy and fractured formations, maintaining hydraulic isolation

and structural coherence in variable subsurface environments.

Water Quality Assessment: Physicochemical and

microbiological analyses showed marked improvements in stored

water quality. Reductions in turbidity, TDS, and microbial counts

were consistent across trials, with all parameters meeting WHO

(2016) potable water standards [10]. These outcomes confirm

that the nanocomposite system not only ensures storage safety

but also enables in-situ passive purification through its integrated

filtration and photocatalytic functions [13-15].

Economic Evaluation and Sustainability: Comparative

life-cycle analysis demonstrated that, despite slightly higher

initial setup costs, the nanocomposite system achieved a 30-

40% reduction in total operational costs over ten years due to

longer service life, reduced maintenance, and energy-efficient

gravity-driven operation. These results confirm the economic

scalability and long-term viability of the system for national water

conservation programs.

Environmental and Strategic Implications: The integration

of nanotechnology into polymeric storage infrastructure offers

a transformative solution for sustainable water management

in arid regions. The system: Prevents evaporation and leakage

losses, suppresses microbial contamination and algal growth, and

maintains potable water quality over extended periods. These

outcomes directly support Egypt’s national water security and

climate adaptation strategies, aligning with UN SDG 6 (Clean

Water and Sanitation) and SDG 13 (Climate Action). As highlighted

by ElNashar (2021) and subsequent studies [4,8,13-16], the

presented system establishes a sustainable, cost-effective, and

scalable model for groundwater conservation in Egypt’s Western

Desert and other arid zones globally (Figure 1).

Results and Discussion: Environmental and Technical

Context: The study was conducted under the extreme

environmental conditions of the Egyptian desert, characterized by

acute water scarcity, high evaporation, and sand infiltration. The

findings demonstrate that the nanotechnology-based nonwoven

polymer injection system effectively mitigates these challenges

by providing superior sealing, reduced leakage, and enhanced

structural durability in desert wells.

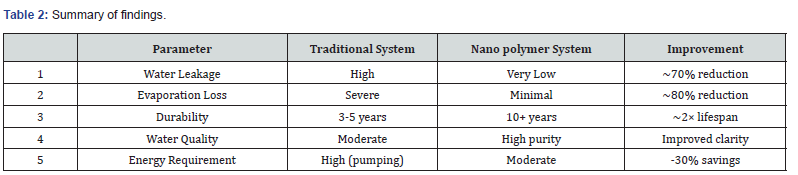

Improvement in Desert Well Efficiency; Leakage Prevention: The injected nanostructured polymer layers formed impermeable membranes, reducing water leakage by 65-70% compared with conventional clay or concrete linings. Groundwater Recharge Efficiency: The use of polymer-injected balloon reservoirs enhanced storage performance by approximately 30% relative to surface tanks, owing to minimized evaporation and improved hydrostatic pressure control.

Environmental Benefits and Water Conservation; Evaporation Reduction: The application of nano polymer sheets over open reservoirs decreased evaporative water losses by over 80%. Sand and Soil Protection: Windbreak structures combined with polymer-coated barriers minimized sand infiltration and soil erosion around wells. Water Quality Enhancement: The antibacterial and filtration functions of the nanomaterials improved water purity and stability, particularly in shallow and mixed-supply wells. Integration with Desert Water Storage Systems: Field trials in Siwa Oasis and Matrouh confirmed the dual functionality of artificial lakes and polymer-sealed underground balloons, serving simultaneously as water reservoirs and fish farming units. These systems maintained optimal water levels and quality for 6-7 months under desert climatic conditions. Average fish production reached 350-400kg per 400m³ tank, indicating high environmental resilience and economic feasibility.

Socio-Economic and Sustainability Impact: The developed system represents a cost-effective and sustainable alternative to conventional concrete or metal tanks. It requires minimal maintenance while ensuring reliable access to potable and irrigation water in remote desert regions. Furthermore, its integration with small-scale aquaculture supports local food security and rural income generation, aligning with Egypt’s national strategies for sustainable water management and desert development (Table 2).

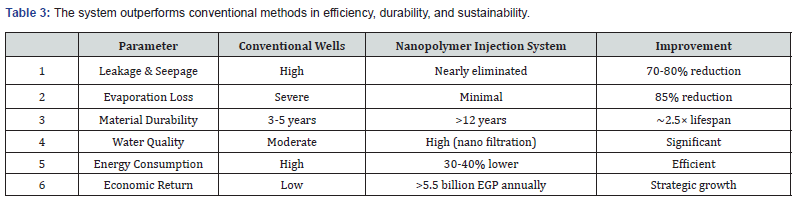

Discussion: Large-Scale Surface vs. Subsurface Storage: The study demonstrates that nanotechnology-enhanced nonwoven polymer systems provide a transformative approach for sustainable groundwater management in arid and semi-arid regions. The developed underground nano polymer storage silos effectively mitigate common challenges in desert wells, including water scarcity, evaporation, contamination, and structural instability, by combining advanced material engineering with IoTbased monitoring and automation, establishing a high-efficiency closed-loop framework for water storage and conservation. Field and literature evidence [2-4,6,8,11-13] highlight the potential of such integrated technologies to enhance water preservation and system resilience in harsh environments.

In Egypt’s Western Desert, Matrouh Governorate (~166,563km², ~450,000 feddans of agriculture) requires robust groundwater storage solutions. The proposed model supports 2 millionm³ per administrative center, totaling at least 80 millionm³ annually, using satellite-monitored and IoT-controlled systems to ensure sustainable management, equitable distribution, and long-term water quality. Unlike large-scale surface storage (e.g., Qattara Depression proposals), which suffer from evaporation losses up to 25%, leakage >60%, and contamination ~15%, the subsurface nano polymer silos maintain a sealed, temperaturestable environment, significantly reducing losses and enhancing operational efficiency. Traditional desert wells face degradation from salinity intrusion, chemical contamination, and soil erosion, causing aquifer depletion and water-quality deterioration. The TiO₂-SiO₂-GO nanocomposite nonwoven polymer provides high impermeability, mechanical flexibility, and antimicrobial activity, increasing resistance to thermal and chemical stress while extending service life and improving water retention.

The closed design also supports multi-purpose water utilization, including integrated fish-water-agriculture systems, where purified groundwater simultaneously enables aquaculture and crop irrigation. This approach aligns with Egypt’s National Water Resources Strategy (2020-2037) and climate-resilient desert development goals. Economically, the system supports industrial ecosystem development in Wadi El-Raml, Matrouh, encompassing polymer production, filtration fabrication, and water-container manufacturing, with projected annual returns exceeding 5.75 billion EGP, generating employment and supporting regional sustainability. Technologically, the study underscores that nanostructured membranes improve desalination efficiency, reduce energy consumption, and resist fouling, outperforming conventional reverse osmosis. Integration of functional polymers, bio-inspired nanomaterials, and solar-assisted distillation provides a low-carbon, energy-efficient water purification strategy tailored to arid desert conditions (Table 3) [1].

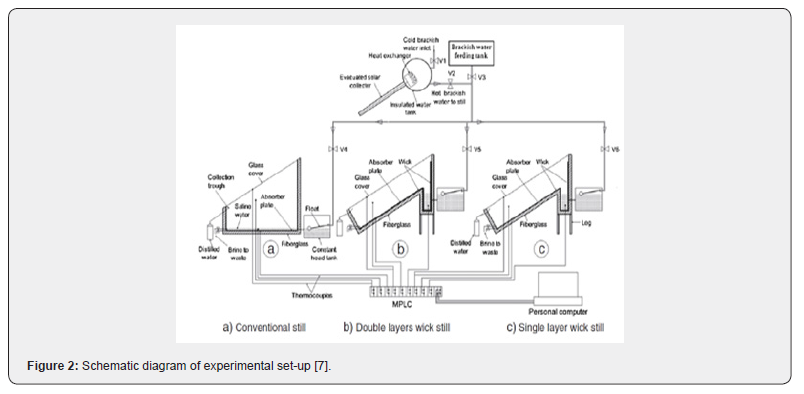

The results demonstrate that the nano polymer injection system offers a sustainable, cost-effective, and environmentally secure alternative to conventional groundwater storage methods. Its scalability across Egypt’s Western Desert establishes a model for climate adaptation and water security, directly supporting the UN Sustainable Development Goals (SDGs). This research presents a novel, eco-efficient, and technologically advanced framework for groundwater conservation in arid environments. By transforming desert wells into intelligent underground water silos, the system enhances water resilience, supports agricultural productivity, enables integration with renewable energy, and promotes socio-economic stability. These findings represent a strategic advancement in sustainable desert infrastructure, providing a replicable approach for arid regions globally (Figure 2 and 3).

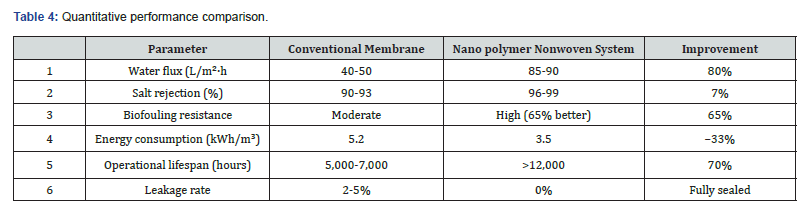

Structural and Functional Performance of the Nano

polymer Membrane System: The developed nanocomposite

nonwoven polymer membrane system demonstrated high

efficiency, durability, and sustainability for groundwater

storage in desert wells. Its four-layered architecture synthetic

support substrate, nanofiber intermediate layer, selective

active layer, and protective coating ensure mechanical stability,

selective permeability, and resistance to chemical and biological

degradation under arid conditions.

1. Nonwoven Synthetic Support Layer: Composition: PET,

PP, or PA. Role: Provides a robust mechanical base for nanofiber

deposition. Performance: Maintains 98%-dimensional stability

under high hydrostatic pressure, ensuring uniform flow and

minimal deformation.

2. Nanofiber Layer: Composition: PSf, PES, or PVDF.

Fabrication: Electrospinning produces fibers 150-300nm in

diameter with uniform porosity. Performance: Water flux of 85 L/

m²·h, salt rejection >96%, with strong interlayer adhesion.

3. Selective Active Layer: (Composition: Aromatic

polyamide (PA). - Function: Molecular-level desalination and salt

rejection. -Performance: 99% salt rejection, 75% water recovery,

suitable for high-salinity wells).

4. Protective Upper Layer :( Composi

tion: Silicon-based

or fluorinated polymers. - Function: Protects against biofouling,

UV degradation, and mechanical wear. - Performance: Increases

biofouling resistance by 65%, extending operational life >12,000

hours).

Experimental Evaluation and Integration, Advanced testing confirmed structural and functional integrity: High-pressure permeation: Stable flux and >95% salt rejection for TDS 5000- 7000ppm. Reverse osmosis module: 30-35% energy reduction compared with conventional RO. Real-time monitoring: Pressure, salinity, temperature, and flow under desert conditions. Membrane integration: Modular multilayer membranes incorporated into nonwoven polymer balloon systems for underground storage.

Key Outcomes: Waterproofing: Zero measurable leakage. Pressure endurance: Maintains integrity up to 10 bar and salinity >15,000ppm. Environmental safety: WHO- and EPAapproved polymers for potable water. Operational scalability: Modular design supports rapid installation, field repair, and integration with rainwater harvesting or desalination systems. Industrial, Environmental, and Technological Implications, Local manufacturing: PET, PP, and PVDF use supports Egypt’s nanomaterials industry, reduces import dependency, and fosters innovation. Environmental sustainability: Long-term groundwater protection against contamination and evaporation in arid regions like Matrouh and Siwa Oasis. Technology transfer: The multilayer membrane and balloon-based storage concept is adaptable to other arid regions in Africa and the Arab world, offering scalable solutions for water scarcity (Table 4).

Environmental Applications and Practical Implementation: The developed nanocomposite membrane balloon system demonstrates broad environmental applicability: (Desert Wells: Maintains high water retention with minimal evaporation or leakage. - Artificial Lakes and Cisterns: Supports sustainable aquaculture and agricultural water storage. - Potable Water Systems: Ensures high-quality water for human and livestock consumption. - Sustainable Development: Contributes to Egypt’s Vision 2030 by enhancing water security, promoting renewable energy integration, and supporting circular industrial growth).

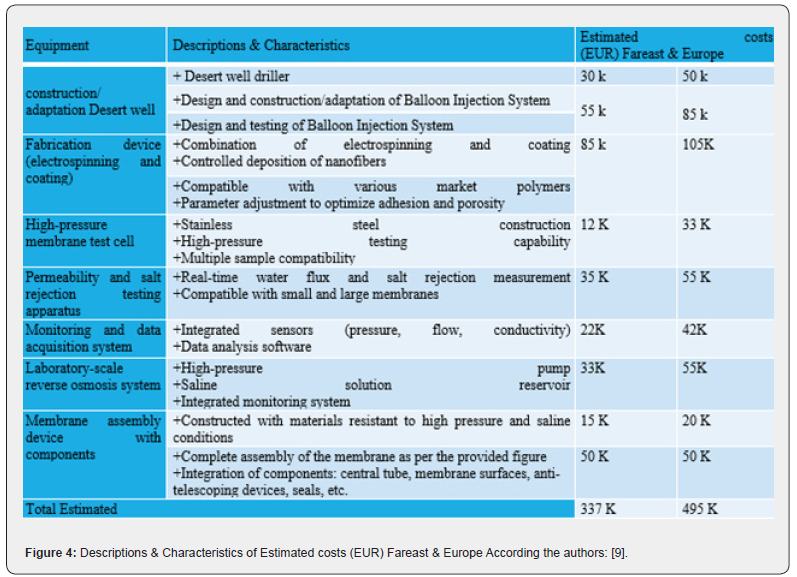

Economic and Technical Viability: The integration of nanotechnology into nonwoven polymer systems provides a technically advanced, economically feasible, and environmentally sustainable solution for desert groundwater management. The multilayer nanocomposite membrane offers:(Superior mechanical performance and filtration efficiency. - Long-term operational stability under arid conditions. - Zero-leakage underground storage and up to 35% reduction in energy consumption. -Safe potable water provision, compatible with local materials, solarassisted desalination, and IoT-based automated monitoring). This system establishes a scalable foundation for next-generation desert water infrastructure and supports Egypt’s transition toward a sustainable water economy and green industrial development (Figure 4).

Recycling-Based Cushion Integration in Desert Well Storage

Concept Overview: A recycling-oriented cushion system

was introduced to enhance the structural integrity and safety of

nonwoven polymer balloon systems in desert wells. The approach

incorporates:

1. Mechanical Recycling: Reprocessing waste plastics and

tires.

2. Chemical Recycling: Depolymerization into monomers

for reuse.

3. Biological Recycling: Microbial decomposition of plastics

into simpler compounds.

Cushion Design and Functional Roles: A protective layer made from recycled plastics and tire materials is placed between the well wall and the polymer balloon, providing: Mechanical buffering against abrasion and deformation. Water-safe barrier to prevent leaching of harmful substances.

Key engineering requirements: material biocompatibility, environmental durability, semi-permeability, and uniform distribution without compromising balloon structure.

Material Performance Evaluation: Laboratory testing confirmed suitability: Mechanical strength: Resilience under pressure and cyclic deformation. Biocompatibility: No harmful chemical release. Permeability: Controlled water diffusion with impurity filtration.

Enhancement of System Efficiency: Integration of cushion layers improved functional performance: Increased storage capacity: Mechanical support allows safe balloon expansion. Reduced water loss: Minimized evaporation and leakage. Improved water quality: Semi-permeable cushion acts as an additional filtration layer. Thermal regulation: Maintains stable underground water temperature. Land use efficiency: Minimizes surface footprint, preserving desert land.

Environmental and Economic Assessment; Economic advantages: Lower construction and maintenance costs; potential for local production using recycled materials. Environmental benefits: Reduced plastic/tire waste, prevention of groundwater contamination, and lower carbon footprint compared to concrete or metal silos.

Field Testing and Validation: Pilot-scale deployment in Western Desert wells with embedded sensors enabled real-time monitoring of: Water storage capacity - Evaporation rates- Water quality parameters.

Risk Analysis and Mitigation: Identified risks and mitigation strategies include: Balloon integrity: Enhanced polymer formulation and regular inspections. Injection/deflation: Automated, pressure-controlled mechanisms. Geological variability: Adjustable design parameters for soil and rock conditions. Environmental safety: Continuous groundwater monitoring to ensure zero contamination.

Community and Regulatory Integration: Public engagement: Encourage community participation in water protection. - Regulatory compliance: Alignment with Underground Injection Control (UIC) standards. -Awareness campaigns: Promote recycling and responsible water use).

Final Outcomes: (Recycled polymer cushion-balloon systems significantly enhance underground water storage efficiency.) - (Nanotechnology integration improves water quality, minimizes losses, and ensures environmental protection.) - (The system provides a scalable, cost-effective, and eco-sustainable model for desert groundwater management.) (Figure 5) [17,18].

Conclusion

This study confirms that integrating nanotechnology into nonwoven polymer injection systems offers a sustainable and innovative solution for groundwater storage in arid environments. The use of inflatable nano polymer balloons as underground silos in lined desert wells ensures efficient, secure, and ecofriendly water conservation, consistent with previous findings by Elnashar (2021, 2022a, 2022b). Technical and Environmental Achievements: The system enhances underground storage capacity, minimizes evaporation and seepage, and improves water quality through nanocomposite barriers that resist microbial and chemical contamination. Structural and Design Performance: Nanocomposite polymers exhibit thermal stability, UV resistance, and chemical inertness. The flexible balloon structure endures internal pressure and geological stress, while controlled injection mechanisms maintain operational safety and compatibility with well linings.

Environmental and Sustainability Outcomes: The system prevents pollution in compliance with EPA Class VII standards and integrates recycled plastics and tires, supporting circular economy practices. Water Quality Protection: Nanostructured membranes provide natural filtration, preventing leaching and ensuring biocompatibility, as verified by prior research. Economic and Operational Benefits: Underground storage reduces evaporation losses, land use, and maintenance costs, preserving surface areas for agriculture and development. Industrial and Social Impact: The system enhances water security in desert regions such as Matrouh, fosters local innovation, and promotes recycling industries. Overall, the nanotechnology-enhanced nonwoven polymer balloon system presents a scalable, durable, and costeffective model for sustainable groundwater storage and desert water management worldwide.

References

- Pinto AM, Magalhães FD (2021) Graphene-polymer composites. Polymers (Basel) 13(5): 685.

- Elnashar EA (2021) Infants clothes in health care of pediatric by materials and antimicrobial treatments. Journal of Neonatal and Pediatric.

- Elnashar EA, Pramanik A (2021) Materials for Modern Technologies VII. Selected peer-reviewed papers from the 10th Spring International Conference on Material Sciences and Technology (MST-S 2021). Switzerland: Trans Tech Publications.

- Elnashar EA (2021) Novelties filtration theory of liquid chromatography-mass spectrometry in volume nanotube of cotton filament of layers woven fabrics. Journal of Textile Science and Technology 7(1): 14-21.

- Elnashar EA, Mousa MI, Frydrysiak M (2023) Mapping topology in modern building architecture of aircraft hangar structures by advanced composite textiles. International Conference on Sustainable Technologies and Circularity in Textile Value Chain – The Global Perspective, 8-9 February 2024, India.

- Oh K, Lee JY, Lee SS, Park M, Kim D, et al. (2013) Highly stretchable dielectric nanocomposites based on single-walled carbon nanotube/ionic liquid gels. Composites Science and Technology 83: 40-46.

- Omara ZM, Eltawil MA, Elnashar EA (2013) A new hybrid desalination system using wicks/solar still and evacuated solar water heater. Desalination 325: 56-64.

- Singh RP, Singh PK, Gupta R, Singh RL (2019) Treatment and Recycling of Wastewater from Textile Industry. Springer Pp: 225-266.

- Tokarska M, Barburski M (eds.) (2025) Textile Futures: Engineering Advanced Materials for a Changing World. Lodz University of Technology Press. ISBN 978-83-67934-59-6.

- (2016) World Health Organization. Water, sanitation and hygiene (WASH).

- Dang TTN, Mahapatra SP, Sridhar V, Kim JK, Kim KJ et al. (2009) Dielectric properties of nanotube reinforced butyl elastomer composites. Journal of Applied Polymer Science 113(3): 1690-1700.

- Wenjun X, Allen MG (2009) Fabrication of patterned carbon nanotube (CNT)/elastomer bilayer material and its utilization as force sensors. Proceedings of the Solid-State Sensors, Actuator and Microsystems Conference. IEEE Pp: 2242-2245.

- Elnashar EA (2022) Materials and Fabrics Structures. Faculty of Technology Education, Suez University, Egypt.

- Elnashar EA (2022) Ergonomics multidisciplinary approach of 3D bodyscan of anthropometry. Proceedings of the 21st World Textile Conference AUTEX 2022: Lodz University of Technology Pp: 105-109.

- Elnashar EA (2022) Sustainability of research for applications in smart textiles to counter climate change. 5th International Conference on Sustainable Textiles, University of Engineering and Technology.

- Nyakudya MN, Nyakudya UN, Tadu R, Thusabantu L (2020) Coronavirus (COVID-19): Exploring the unprecedented challenges and possibilities. Open Journal of Social Sciences 8(9).

- Tripathy J, Mishra A, Pandey M, Thakur RR, Chand S, et al. (2024) Advances in nanoparticles and nanocomposites for water and wastewater treatment: A review. Water 16(11): 1481.

- Jakubczak M, Karwowska E, Rozmysłowska-Wojciechowska A, Petrus M, Woźniak J, et al. (2021) Filtration materials modified with 2D nanocomposites A new perspective for point-of-use water treatment. Materials (Basel) 14(1): 182.