Abstract

Circular material design is a growing trend in the textile and automotive sectors, driven by sustainability targets and regulatory pressures. This case study reports on the transition from multi-material automotive floor mats to a mono-material design using recycled polyester (rPET) derived from Eastman’s methanolysis, a material-to-material chemical recycling process. The newly designed floor mats are assembled as Volkswagen Atlas floormats and represent a significant step toward circular material systems in automotive applications. This paper compares conventional versus mono-material mat architectures, outlines their performance characteristics, and evaluates carbon footprint reduction. The shift to single-material construction facilitates easier disassembly and chemical recycling, advancing closed-loop goals without compromising mechanical performance or aesthetics.

Keywords: Automotive Textiles and fibers; Mono-material design; Chemical Recycling; Methanolysis; Circular Economy; Floor Mats

Abbreviations: rPET: Recycled polyester; EoL: End-of-life

Introduction

Sustainable product design is a growing imperative in the automotive industry, where interior components often consist of heterogeneous materials, hindering recyclability and increasing lifecycle emissions [1-3]. Floor mats, typically fabricated with multiple polymer layers, are particularly challenging to recycle [4]. The automotive industry, on the other hand, is increasingly under pressure to decarbonize and transition toward circular material flows. This is in response to tightening EU end-of-life (EoL) vehicle regulations (Directive 2000/53/EC) and OEM carbon neutrality commitments [5] which causes a transition to mono-material, recyclable.

Mono-material design focuses on using a single type of material, like a specific polymer or bio-based material, for product manufacturing, especially for plastic products. The aim is to create products that are easier to recycle and support a circular economy. This involves designing products using circular and biodegradable polymers made of a single monomer, enabling tailorable proper ties without altering the chemical makeup or composition [6]. As mentioned, interior components such as floor mats represent a significant challenge due to their multi-layered, multi-material construction, which complicates EoL separation and recycling.

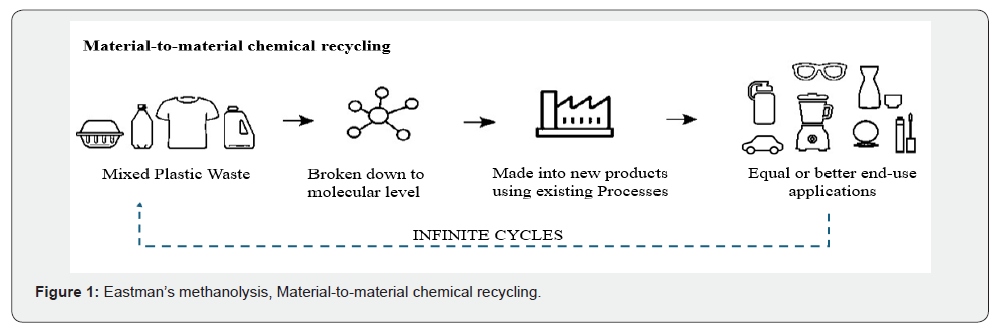

Traditionally, floor mats include combinations of textile tops, foam or fiber cores, and rubber or plastic backings, each requiring distinct recycling pathways or leading to landfill disposal or incineration. To address this, Volkswagen Group of America- Innovation Hub Knoxville collaborated with Eastman Chemical co and Visscher-Caravelle to develop and test a fully PET-based mono-material floor mat solution compatible with Eastman’s methanolysis Figure 1 [7], a form of chemical recycling that depolymerizes PET waste into virgin-quality recycled monomers that can be used to produce new polyesters. This case study presents a redesign initiative within the Volkswagen Atlas template leveraging Eastman’s chemically recycled PET and Visher Caravel’s floor mat design and production.

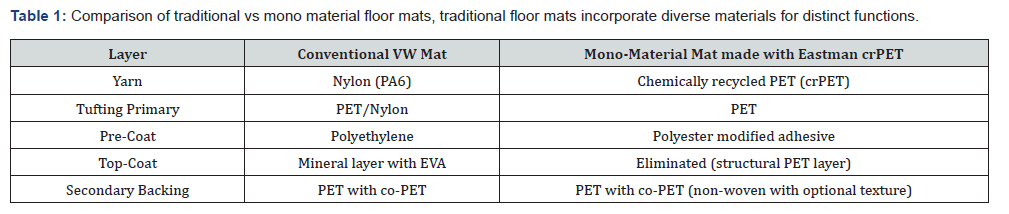

Eastman’s methanolysis is a molecular recycling technology that depolymerizes PET waste into its monomers, enabling the production of virgin-quality rPET. Unlike mechanical recycling, Eastman’s process tolerates mixed plastic streams and hard-to-recycle plastics, such as colored and opaque PET making it ideal for automotive interior upcycling Table 1 [7]. Eastman’s technology unzips polyesters, using methanolysis to convert them back to their basic monomers and create new materials. The molecules produced are indistinguishable from materials made with virgin or nonrecycled content. This process, also known as depolymerization, allows Eastman to recycle polyester waste again without degradation over time and reduces greenhouse gas emissions at the intermediate level compared to processes using fossil fuels. Eastman’s new methanolysis facility in Kingsport, Tennessee became operational in early 2024 with the capacity to recycle 110,000 metric tons annually.

Material Structure and Design Comparison

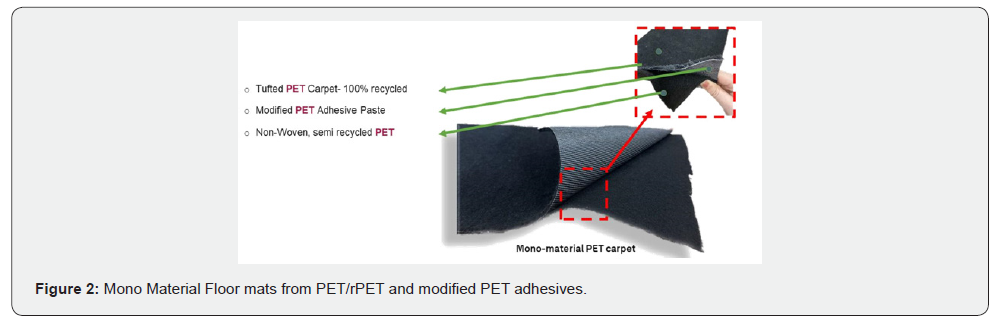

The floor mat prototype consists of the following layers:

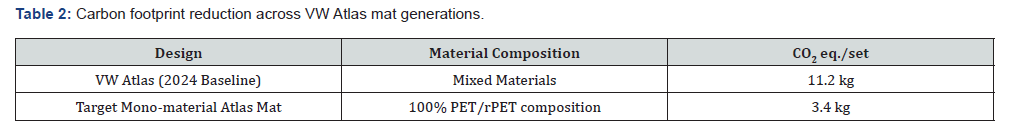

A top surface consistence of a tufted rPET yarn, UV stabilized, colored and textured for durability and appearance. The rPET resin used to produce yarn is made from Eastman’s methanolysis process. The tufted yarn is attached to a PET felt, providing structural resilience and then laminated with a modified PET adhesive to a bottom Layer consisting of rPET-based fiber arranged in a non-woven form providing anti-slip function. All layers are made from polyester (also containing recycled content), using Eastman’s chemically recycled PET where possible. No additional adhesives, latexes, or non-PET barriers were used, allowing full mono-material classification. The multi-material architecture complicates recycling due to incompatibility of layers during reprocessing. Conversely, a single PET-based design allows the opportunity for closed-loop recycling using existing PET streams Table 2.

Performance Validation

The mono-material mats were validated through testing protocols including:

• Abrasion resistance: matched or exceeded nylon-based

control

• Dimensional stability: acceptable shrinkage within OEM

tolerances

• Flogging, VOC and odor: compliant with indoor air standards

• Slip resistance meets anti-skid standards

Such validation demonstrates that sustainable redesign needs not sacrifice functional performance, aligning with findings by Quinn et al. [6] on mono-material composites. The study focuses on the concept and benefits of using single-material design in transportation to facilitate recycling and achieve a circular economy, thereby addressing environmental concerns related to waste and resource depletion [6].

Environmental Impact and Circularity

Circular Design Benefits

Mono-material PET floor mats offer significant advantages in advancing circular design principles. by using a single polymer family, these mats simplify EoL handling. The vision is to use Eastman’s chemical recycling technology to enable a cradle-to-cradle lifecycle. The uniform material composition eliminates the need for complex sorting, facilitating straight forward collection and efficient reprocessing and potential recycling through Eastman’s methanolysis process. These mats are designed to be compatible with both mechanical and chemical recycling technologies, including advanced processes like methanolysis. Additionally, mono- material construction enhances recyclability and traceability of material content across the value chain and makes it easy to separate these mats as they can be removed during routine service or vehicle reconditioning, well before mats or vehicle EoL, preventing them from ending up in landfills. This proactive recoverability ensures that valuable materials are continuously looped back into production systems through recycling either chemical or mechanical, supporting both sustainability targets and regulatory compliance.

Mono-material PET mats support a cradle-to-cradle system:

• Single-material identification simplifies collection and

reprocessing

• Compatibility with both mechanical and chemical recycling

pathways

• Enables transparency and traceability of material content

Life Cycle CO₂ Footprint

This data aligns with prior LCA studies by van der Velden et al. [8] indicating a significant CO2 reduction potential when shifting from nylon to PET or rPET and plastic recycling. Also, a report by Geyer et al. [9] shows that of the 8.3 billion metric tons of plastics ever produced, only 9% has been recycled, 12% incinerated, and 79% accumulated in landfills or the natural environment. These new floor mats can replace approximately 14 kg of fiber materials used in a single VW Atlas. They also enhance recyclability and help reduce the amount of waste sent to landfills and incinerators.

Implementation Challenges and Solutions

Key technical and strategic hurdles included:

• Material Behavior: PET’s thermal profile required adjustments

in all steps of the manufacturing process.

• Supplier Alignment: Coordinated with Eastman and Tier

1 supplier such as Visscher-Caravelle for material supply assurance

• Consumer Perception: Maintained high aesthetic standards

to ensure user acceptance

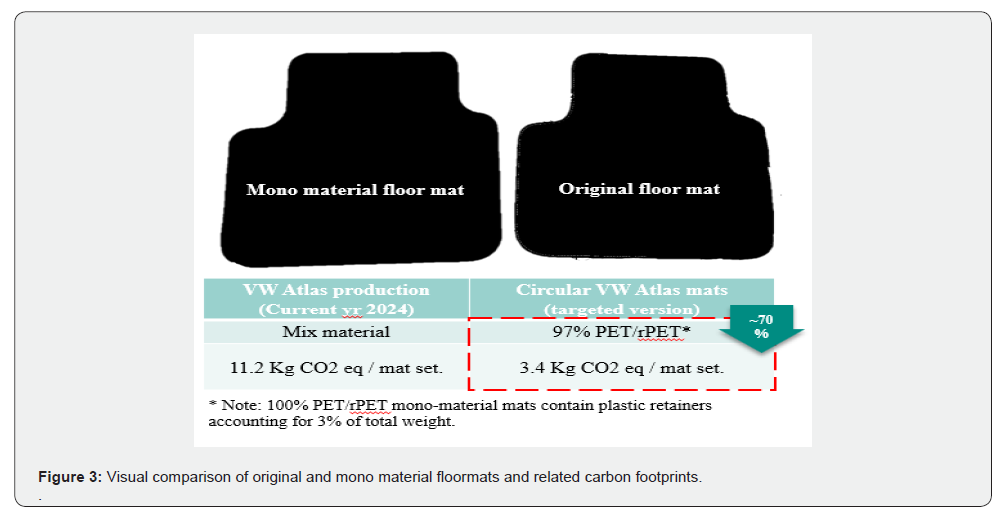

As highlighted by Masoumi et al. [10] and [11], successful implementation of circular materials in automotive supply chains requires more than just technical readiness, it demands strategic alignment across stakeholders, clear communication of sustainability goals, and long-term partnerships. Their findings emphasize that OEMs play a pivotal role in initiating and facilitating change by setting clear environmental targets, encouraging innovation, and incentivizing suppliers to adopt circular practices. In the case of the mono-material PET floor mats Figure 2, Volkswagen’s leadership and integration with Eastman and Visscher Caravelle as two main suppliers exemplify how such alignment and proactive collaboration can help overcome traditional barriers, such as risk aversion and lack of supplier readiness, accelerating the adoption of sustainable material innovations. Therefore, OEM leadership and cross-functional collaboration could lead to overcoming inertia typically associated with sustainable material substitution Figure 3.

Conclusions and Future Directions

This case report on redesigning Volkswagen Atlas floor mats reports the successful implementation of a mono-material design for automotive floor mats using chemically recycled PET, enabled by Eastman’s methanolysis process transitioning from complex, multi-material constructions to a simplified PETbased architecture, the Volkswagen Group, in collaboration with Eastman and Visscher Caravelle, has demonstrated that sustainable innovation can meet the demanding performance, aesthetic, and environmental requirements of the automotive industry. The mono-material PET mats not only simplify recycling logistics and enable cradle-to-cradle reuse but also significantly reduce carbon emissions, achieving up to a 70% reduction in CO2 equivalent per mat set compared to the conventional version. This circular approach allows early removal and recovery of mats, minimizing landfill disposal even during mid-life service. These results show the importance of mono-material strategies as a solution for advancing circularity in automotive interiors. Future work will focus on scaling this model across other interior components and expanding mono-material concepts to other trim components (e.g., door panels, trunk liners).

References

- Kia A, et al. (2021) Challenges and strategies for recycling polymer-based automotive parts. Journal of Cleaner Production 314: 127914.

- Jody J, Daniels EJ, Duranceau CM, Pomykala JA, Spangenberger JS (2011) End-of-life vehicle recycling: state of the art of resource recovery from shredder residue.

- Vieyra H, Molina-Romero JM, Calderón-Nájera JDD, Santana-Díaz A (2022) Engineering, recyclable, and biodegradable plastics in the automotive industry: a review. Polymers 14(16): 3412.

- Zheng J, Arifuzzaman M, Tang X, Chen XC, Saito T (2023) Recent development of end-of-life strategies for plastic in industry and academia: bridging their gap for future deployment. Materials Horizons 10(5): 1608-1624.

- Volkswagen Group (2023) Way to Zero Report.

- Quinn EC, Knauer KM, Eckham GT, Chen EYX (2023) Mono-material product design with bio-based, circular, and biodegradable polymers. One Earth 6(6): 582-585.

- Eastman (2023) Sustainability Full Report, Polyester Renewal Technology.

- Van der Velden, Natascha M, Martin K Patel, Joost G Vogtländer (2014) "LCA benchmarking study on textiles made of cotton, polyester, nylon, acryl, or elastane." The International Journal of Life Cycle Assessment 19(2014): 331-356.

- Geyer R, Jambeck JR, Law KL (2017) Production, use, and fate of all plastics ever made. Science Advances 3(7): e1700782.

- Masoumi SM, Kazemi N, Abdul-Rashid, SH (2019) Sustainable supply chain management in the automotive industry: A process-oriented review. Sustainability 11(14): 3945.

- Directive 2000/53/EC. Design and production, End-of-life vehicles. European Parliament.