Evolutionary Significance and Sustainable Applications of Coarser Grade Wool Fibers: A Review

Vaibhav Vankundre1 and Shishir Tyagi2*

1Senior Research Fellow, Wool Research Association, Centre of Excellence for Sportech, India

2Senior Deputy Director, Wool Research Association, Centre of Excellence for Sportech, India

Submission: December 27, 2023;Published: January 11, 2024

*Corresponding author: Shishir Tyagi, Senior Deputy Director, Wool Research Association, Centre of Excellence for Sportech, India

How to cite this article: Vaibhav V, Shishir T. Evolutionary Significance and Sustainable Applications of Coarser Grade Wool Fibers: A Review. Curr Trends Fashion Technol Textile Eng. 2024; 9(1): 555751. DOI: 10.19080/CTFTTE.2024.09.555751

Abstract

The building sector, responsible for a substantial portion of global energy consumption and carbon emissions, underscores the need for enhanced energy efficiency. In 2018, the residential sector accounted for 22% of the world’s total energy consumption. Traditional insulators like polyurethane foams and polystyrene are energy-intensive and have high embodied energy. In response, there is a growing demand for sustainable and eco-friendly products as a natural thermal insulator such as: sheep wool due to its properties. Sheep wool’s ability to regulate temperature and contribute to energy efficiency aligns with the increasing global focus on sustainable building materials. These abstract highlights the current research trend and rising interest in adopting sheep wool for greener and more sustainable construction practices.

Keywords: Thermal insulator; Sheep wool; Sustainability; Ecofriendly

Introduction

Wool, a highly intricate protein that has evolved over millions of years, plays a crucial role in facilitating the survival of certain animals in diverse environments. Derived from the fiber follicles present in the skin of sheep, wool exhibits notable variations influenced by factors such as sheep health, diet, species, breeds, and climate change [1,2]. This review explores the multifaceted nature of wool fibers, encompassing physical characteristics like staple length, crimp number, fiber type, and diameter, as well as chemical properties including scouring yield and wool wax [3].

The multipurpose appeal of wool stems from its high demand, primarily driven by its unique physical features that directly impact wearer comfort, processing performance, durability, and textile qualities [4]. Utilized in the production of garments, carpets, draperies, upholstery, and blankets, wool extends its applications to include industrial uses such as incubator insulators. Additionally, coarse quality wool, exemplified by fleece from Menz sheep, finds purpose in the creation of woolen sheets, felted goods for saddlery, and coarse blankets for equines and canines. Beyond traditional applications, wool is also employed in crafting handbags and wall decorations.

Examining global trends, the review projects a substantial growth in the global sheep population, anticipated to rise from 1.7 billion in 2000 to 2.7 billion by 2050. Region-specific distinctions, including CWANA, ESAP, LAC, NAE, and SSA, underscore the global contributions to this surge. Against this backdrop, researchers are actively developing innovative techniques to leverage natural wool over synthetic alternatives, aiming to enhance environmental sustainability and cost-effectiveness.

In conclusion, this scientific introduction synthesizes a comprehensive overview of wool, exploring its evolutionary significance, global population trends, sustainable applications, and potential contributions to thermal energy storage. Referenced studies provide a foundation for further exploration, making this review a valuable resource for researchers, practitioners, and stakeholders invested in the intricate world of wool and its sustainable utilization.

Wool Morphology

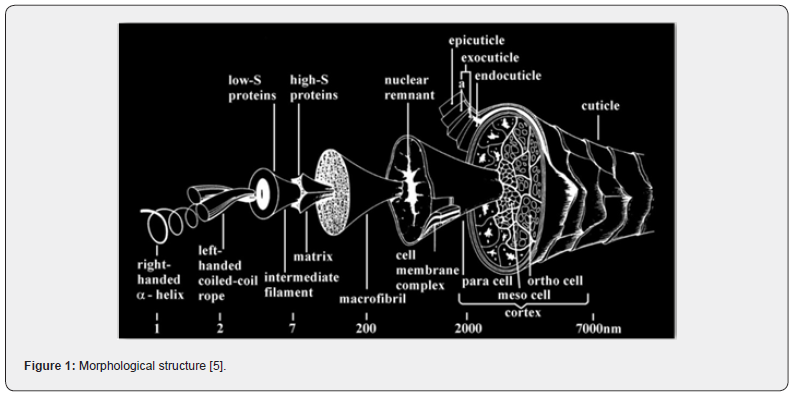

Wool fibers have unique frictional properties due to overlapping cuticle cells and a cortex with ortho-, para-, and meso-cortex cells influencing fiber crimp. The cuticle layers, including epicuticle, exocuticle, and endocuticle, make wool water- and soil-repellent. Key physical properties like staple length, crimp, fiber type (wool, hetero, hairy/kemp) and fiber diameter impact quality and value. Staple length correlates with processing success, crimpiness affects spinning capacity, and fiber type is influenced by follicle ratios, genotype, and age. Fiber diameter, measured in millimicrons, determines wool pricing and processing capabilities. These characteristics make wool valuable for low-maintenance carpets [5-8] (Figure 1).

Wool Advantages

a) Naturally processed, minimizing allergy risks.

b) Hypoallergenic, resisting dust mites and mold.

c) Non-flammable, enhancing safety in fire incidents.

d) Well-established safety record in insulation without requiring safety gear.

e) Low in volatile organic compounds (VOCs), improving indoor air quality.

f) Health benefits include improved sleep and reduced infection risks.

g) Provides UV protection, acts as a static electricity barrier, and excels in sound insulation.

h) Breathable, actively manages perspiration, ensuring wearer-sensitive comfort.

i) Adapts to temperature changes for year-round comfort.

j) Easy to care for, machine washable, and resistant to odor, stains, and quick drying.

Wool Disadvantage

a) Attracts moths due to cystine linkage or sulfur content.

Synthetic Insulator Drawbacks

a) High embodied energy.

b) Significant environmental impact.

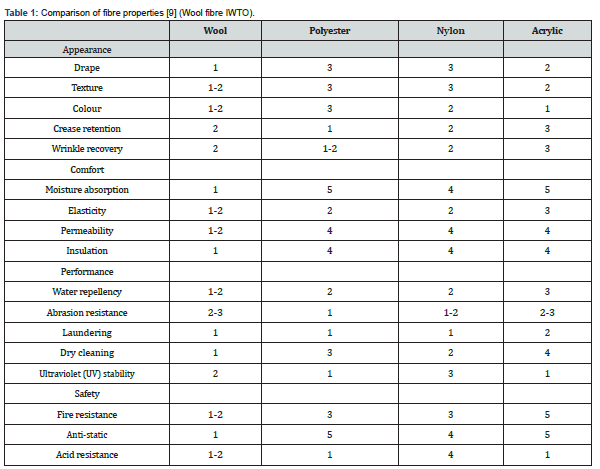

c) Expensive [6] (Table 1).

Sheep Wool Production and Consumption

Globally, a single sheep contributes about 4.5 kg of wool annually, resulting in a total production of 1,977.3 million kilograms (mkg) of greasy wool and 1,051.2 mkg of clean wool in 2022. China leads in sheep population with 1.296 billion, followed by India and Australia. The wool industry, spanning various products from clothing to carpets, is undergoing global expansion, particularly notable in Australia, where production surged by 11% in 2022 [9,10].

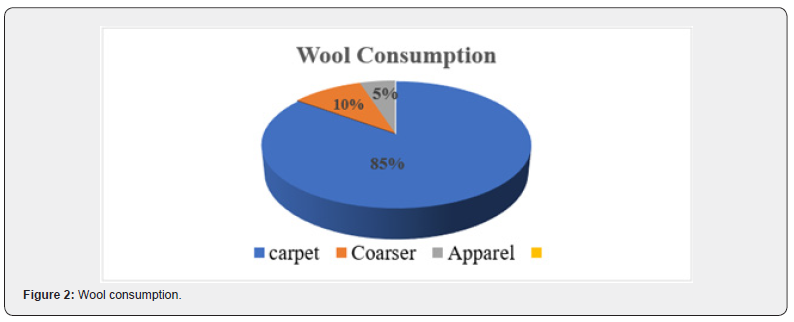

In India, although the woolen textile sector is smaller than its cotton and synthetic counterparts, it plays a pivotal role in bridging rural and urban economies. In the fiscal year 2018- 19, India, boasting the world’s third-largest sheep population, produced 40.42 million kg of raw wool, predominantly used for carpets (85%), clothing (5%), and coarser wool applications. Despite an average yearly sheep production of 0.9 kg, below the global average of 2.4 kg, the industry significantly contributes to India’s textile landscape [10,11] (Figure 2).

Note: Grades on scale from 1 = excellent, 2 = very good, 3 = good, 4 = moderate, 5 = poor

Insulation refers to the resistance of heat transfer, reducing heating and cooling costs and enhancing comfort in homes. The demand for energy-efficient and eco-friendly buildings has grown globally to address increased energy consumption and greenhouse gas emissions from the construction sector. Thermal insulation in buildings is crucial for meeting energy demands, minimizing temperature fluctuations, and ensuring occupant comfort in various climates. Insulating materials are utilized in building enclosures to regulate temperature and comply with heating and cooling requirements [12,13].

Thermal Properties

Thermal Conductivity (“k”): characterizes the heat transmission capability of insulating materials, with lower values denoting enhanced insulation. Fourier’s law and ISO 9869-1 standards, evaluating thermal resistance (R) and transmittance (U), rely on key equations. Material thickness influences R and U, while heat capacity, diffusivity, and effusivity impact the rate at which materials reach a thermal equilibrium. Equations (4) and (5) establish the relationships between thermal conductivity, specific heat capacity, and density.

Apparent Density

Reducing apparent density is advantageous for thermal conductivity in construction. Lower apparent density correlates with improved insulation, as illustrated in the relationship between apparent density and thermal conductivity.

Fire Resistance

Critical for safety, fire resistance categorizes materials from highly flammable to incombustible per European standard BS EN 13501-1. Classification considers factors like temperature increase, fire growth rate, smoke growth rate, flame spread, and total smoke output [14].

Sheep Wool in Construction

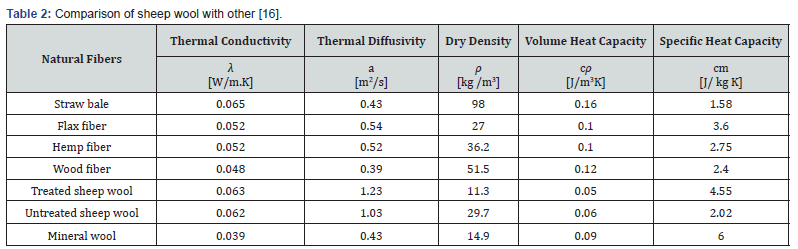

Sheep wool, traditionally used in textiles, has gained traction in Western Europe’s insulation market. In Bosnia and Herzegovina, it is primarily utilized for interior decoration [15]. Recognized for properties akin to conventional materials, sheep wool-based thermal insulators emerge as eco-friendly alternatives to synthetic counterparts. Applications include roofs, walls, and concrete slab floors [16]. Notably, sheep wool insulation exhibits lower environmental impact (5.4 kg CO2/m3) than mineral wool (135 kg CO2/m3) and maintains stable hygrothermal conditions, reducing the risk of mold growth [17]. Innovative projects, such as Fitness and Cartonlana, showcase the development of sustainable insulation panels from sheep wool and hemp fibers [18,19]. Researchers have repurposed sheep wool and agricultural remnants into effective insulation panels [20-22]. Bamboo, valued for its eco-friendly characteristics, holds potential for thermal insulation in construction [23] (Table 2).

Insulation refers to the resistance of heat transfer, reducing heating and cooling costs and enhancing comfort in homes. The demand for energy-efficient and eco-friendly buildings has grown globally to address increased energy consumption and greenhouse gas emissions from the construction sector. Thermal insulation in buildings is crucial for meeting energy demands, minimizing temperature fluctuations, and ensuring occupant comfort in various climates. Insulating materials are utilized in building enclosures to regulate temperature and comply with heating and cooling requirements [12,13].

Thermal Properties

Thermal Conductivity (“k”): characterizes the heat transmission capability of insulating materials, with lower values denoting enhanced insulation. Fourier’s law and ISO 9869-1 standards, evaluating thermal resistance (R) and transmittance (U), rely on key equations. Material thickness influences R and U, while heat capacity, diffusivity, and effusivity impact the rate at which materials reach a thermal equilibrium. Equations (4) and (5) establish the relationships between thermal conductivity, specific heat capacity, and density.

Apparent Density

Reducing apparent density is advantageous for thermal conductivity in construction. Lower apparent density correlates with improved insulation, as illustrated in the relationship between apparent density and thermal conductivity.

Fire Resistance

Critical for safety, fire resistance categorizes materials from highly flammable to incombustible per European standard BS EN 13501-1. Classification considers factors like temperature increase, fire growth rate, smoke growth rate, flame spread, and total smoke output [14].

Sheep Wool in Construction

Sheep wool, traditionally used in textiles, has gained traction in Western Europe’s insulation market. In Bosnia and Herzegovina, it is primarily utilized for interior decoration [15]. Recognized for properties akin to conventional materials, sheep wool-based thermal insulators emerge as eco-friendly alternatives to synthetic counterparts. Applications include roofs, walls, and concrete slab floors [16]. Notably, sheep wool insulation exhibits lower environmental impact (5.4 kg CO2/m3) than mineral wool (135 kg CO2/m3) and maintains stable hygrothermal conditions, reducing the risk of mold growth [17]. Innovative projects, such as Fitness and Cartonlana, showcase the development of sustainable insulation panels from sheep wool and hemp fibers [18,19]. Researchers have repurposed sheep wool and agricultural remnants into effective insulation panels [20-22]. Bamboo, valued for its eco-friendly characteristics, holds potential for thermal insulation in construction [23] (Table 2).

Other application of wool

Geotextile

Wool, particularly low-demand wool from sheep breeding, proves economically justified for geotextile production. Ropes made from recycled textile waste, especially wool-based ones, show potential in slope protection, erosion prevention, and moisture retention [33].

Filtration

Wool’s unique properties make it increasingly popular in filtration applications. In air filtration, wool-based filters exhibit high efficiency in trapping particles, while in liquid filtration, wool’s hydrophobic nature makes it effective in separating oil and water. Its use extends to industrial filtration, environmental remediation, marine filtration, and biomedical applications [34- 39].

Agrotech

Wool, a biodegradable fiber, offers benefits in agrotech. Its moisture absorption and retention capabilities make it effective in soil applications, contributing to water conservation. Wool waste serves as an organic mulch, soil amendment, slow-release fertilizer, and composting material, showcasing its sustainable and diverse applications in agriculture [40-45].

Aquaculture

Research explores the potential of wool ropes in seaweed farming, presenting an eco-friendly alternative to plastic. However, further research is needed to determine commercial viability and durability [46].

Existing Woolen Products:

Various Coarser grade wool-based products, such as non-woven mats, insulation materials, mulch mats, and felted blankets, offer sustainable solutions in erosion control, landscaping, insulation, and weed suppression [47].

Wool-based solutions abound in sustainable applications. Cirtex BioWool 400 offers non-woven wool matting for slope protection. Geofabrics NZ’s Biomac Woolmulch, a 100% wool mat with jute mesh, aids plant growth and inhibits weeds. EcoWool Mulch Mats by Advanced Landscape Systems use 100% waste wool for soil conservation. Twool® twine, a British alternative to jute, is strong and compostable. Thermafleece Original combines 85% wool and 15% polyester for superior insulation. Woolch™ is a sustainable blend of recycled wool and wood for weed control. Brookside Woolen Mill’s Needle Felted Wool Blanket offers versatility in weights. Wool Battings from Sugar Loaf and Thirteen Mile Wool Company are used for bedding and insulation. Ero- Guard Inc.’s Wool/Straw ECB combines wool and straw for erosion control [47].

Conclusion

Coarser grade Sheep wool, once considered waste, emerges as a sustainable solution in construction, filtration, agriculture, and more. Its natural properties contribute to energy efficiency, environmental sustainability, and a resilient future. Ongoing research continues to explore and expand the applications of sheep wool, emphasizing its crucial role in fostering a greener and more sustainable world.

References

- Baba MA, Ahanger SA, Hamadani A, Rather MA, Shah MM (2020) Factors affecting wool characteristics of sheep reared in Kashmir, Trop Anim Health Prod 52: 2129-2133.

- Khan MJ, Asad A, Mazhar A, Muhammad N, Muhammad S, et al. (2012) Factors affecting wool quality and quantity in sheep. Afr J Biotechnol. 11(73): 13761-13766.

- Lakshmanan A (2022) Physical and chemical properties of wool fibers, in: Wool Fiber Reinforced Polymer Composites.

- Szatkowski P, Tadla A, Flis Z, Szatkowska M, Suchorowiec K, et al. (2021) The potential application of sheep wool as a component of composites, Roczniki Naukowe Polskiego Towarzystwa. Zoo Technic znego 17(4).

- Allafi F, Hossain MS, Lalung J, Shaah M, Salehabadi A, et al. (2022) Advancements in Applications of Natural Wool Fiber: Review. J Natural Fibers 19(2): 497-512.

- Speakman PT (1985) Wool fibres.

- Botha AF, Hunter L (2010) The measurement of wool fibre properties and their effect on worsted processing performance and product quality. Part 1: The objective measurement of wool fibre properties. Textile Progress 42(4): 227-339.

- Gelaye G, Sandip B, Mestawet T (2022) A Review on Some Factors Affecting Wool Quality Parameters Of Sheep, Afr J Food Agri Nutr Dev 21(10): 18980-18999.

- IWTO-MIR-2023_sample_watermark, (n.d.).

- Henry B (2012) Understanding the environmental impacts of wool: A review of Life Cycle Assessment studies.

- “Wool and Woollen Textiles Sector,” n.d.

- Ijjada N, Nayaka RR (2022) Review on properties of some thermal insulating materials providing more comfort in the building, Mater Today Proc 58(4): 1354-1359.

- Kumar A, Prince LL, Jose S (2017) Sustainable wool production in India, in: Sustainable Fibres and Textiles p. 87-115.

- Cosentino L, Fernandes J, Mateus R (2023) A Review of Natural Bio-Based Insulation Materials. Energies (Basel) 16.

- Volf M, Diviš J, Havlík F (2015) Thermal, moisture and biological behaviour of natural insulating materials. Energy Procedia 78: 1599-1604.

- Parlato MCM, Porto SMC (2020) Organized framework of main possible applications of sheep wool fibers in building components. Sustainability Switzerland 12.

- Korjenic A, Klaric S, Hadžic A, Korjenic S (2015) Sheep wool as a construction material for energy efficiency improvement, Energies (Basel) 8: 5765-5781.

- Campbell N, McGrath T, Nanukuttan S, Brown S (2017) Monitoring the hygrothermal and ventilation performance of retrofitted clay brick solid wall houses with internal insulation: Two UK case studies. Case Studies Construct Materials 7: 163-179.

- Pennacchio R, Savio L, Bosia D, Thiebat F, Piccablotto G, et al. (2017) Sheep-wool and Hemp Sustainable Insulation Panels. Energy Procedia 111: 287-297.

- Bosia D, Di Torino P, Giordano R, Savio L (2011) A sustainable building product: advanced insulation panels obtained by recycling regional sheep’s wool. Techne - J Tech Architect Environ.

- Giordano R, Savio AL, Human D, Bosia D, Thiebat F, et al. (2015) Natural is always Ecological? From a study concerning the environmental impact of building insulating wool to the awareness to promote a SLOW TECH approach in architecture (n.d). Science direct 78: 315-320.

- Bosia D, Savio L, Thiebat F, Patrucco A, Fantucci S, et al. (2015) Sheep wool for sustainable architecture. Energy Procedia 78: 315-320.

- Savio L, Pennacchio R, Patrucco A, Manni V, Bosia D (2022) Natural Fibre Insulation Materials: Use of Textile and Agri-food Waste in a Circular Economy Perspective. Materials Circular Economy 4(6).

- Tiza TM, Singh SK, Kumar L, Shettar MP, Singh SP (2021) Assessing the potential of Bamboo and sheep wool fiber as sustainable construction materials: A review. Mater Today Proc 47(14): 4484-4489.

- Atbir A, El Wardi FZ, Khabbazi A, Cherkaoui M (2019) Thermophysical study of a multi-layer brick of grids made of sheep’s wool yarn and clay, in: AIP Conf Proc, American Institute of Physics Inc.

- Mounir S, Khabbazi A, Khaldoun A, Maaloufa Y, El Hamdouni Y (2015) Thermal inertia and thermal properties of the composite material clay-wool. Sustain Cities Soc 19: 191-199.

- Atbir A, Taibi M, Aouan B, Khabbazi A, Ansari O, et al. (2023) Physicochemical and thermomechanical performances study for Timahdite sheep wool fibers application in the building’s insulation. Sci Rep 13: 5038.

- Bharath KN, Manjunatha GB, Santhosh K (2019) Failure analysis and the optimal toughness design of sheep-wool reinforced epoxy composites, in: Failure Analysis in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites p. 97-107.

- Xing Y, Brewer M, El Gharabawy H, Griffith G, Jones P (2018) Growing and testing mycelium bricks as building insulation materials. IOP Conf Ser Earth Environ Sci 121(2).

- Stapulionienė R, Vaitkus S, Vėjelis S (2017) Development and research of thermal-acoustical insulating materials based on natural fibres and polylactide binder, in: Materials Science Forum, Trans Tech Publications pp. 123-128.

- Whitman CJ, Armijo G, Schiappacasse LN (2015) Methodology for informed design of sustainable tourism accommodation in Chile’s 9th Region the Gateway to Patagonia, in: Energy Procedia 78: 267-272.

- Omidi A, Jahangiri M, Mohammadidehcheshmeh F, Mostafaeipour A (2021) Comprehensive assessment of agricultural waste effect on the thermal bridge phenomenon using ZUB ARGOS software, A case study in Iran. Energy Build 245.

- Chmura D, Salachna A, Broda J, Kobiela MK, Gawłowski A, et al. (2022) Multifunctional Geotextiles Produced from Reclaimed Fibres and Their Role in Ecological Engineering, Materials 15.

- Najafabadi SAN, Ding E, Hobeika N, Bluyssen PM (2023) Do wool carpets ‘clean’ the air or not? A study on the sorption effects of wool carpets by sensory evaluation. IndoorBuilt Environ 33(1).

- Pang L, Lin S, Krakowiak J, Yu S, Hewitt J (2022) Performance analysis of sheep wool fibres as a water filter medium for human enteric virus removal. J Water Process Engineer 47.

- El Sayed H, Kantouch A, Raslan WM (2004) Environmental and technological studies on the interaction of wool with some metal ions, Toxicol Environ Chem 86(3).

- Reddie RN, Nicholls CH (1971) Absorption of Formaldehyde by Wool. Textile Res J 41(4).

- Muir Brown R (1994) The Microbial Degradation of Wool in the Marine Environment.

- Islam S, Arnold L, Padhye R (2012) Wound dressing utilizing nonwoven wool matrix, in: Adv Mat Res 1534-1541.

- Juhos K, Papdi E, Kovács F, Vasileiadis VP, Veres A (2023) The Effect of Wool Mulch on Plant Development in the Context of the Physical and Biological Conditions in Soil, Plants 12(3): 684.

- Adi M, Păcurar I (2015) Study on the Use Sheep Wool, in Soil and Fertilozation as the Mixture into Cubes Nutrients, ProEnvironment/ProMediu 8(22).

- Zheljazkov VD (2005) Assessment of Wool Waste and Hair Waste as Soil Amendment and Nutrient Source, J Environ Qual 34(6): 2310-2317.

- Nustorova M, Braikova D, Gousterova A, Vasileva TE, Nedkov P (2006) Chemical, microbiological and plant analysis of soil fertilized with alkaline hydrolysate of sheep’s wool waste. World J Microbiol Biotechnol 22: 383-390.

- Tiwari VN, Pathak AN, Lehri LK (1989) Effect of cattle dung and rock phosphate on composting of wool waste. Biol Wastes 27(3): 237-241.

- Hustvedt G, Meier E, Waliczek T (2016) The feasibility of large-scale composting of waste wool, in: Environmental Footprints and Eco-Design of Products and Processes. Green Fashon 95-107.

- Drury KE, Crotty FV (2022) Developing the Use of Wool Rope within Aquaculture. Syst Rev Sustainabil Switzerland.

- Pokorny M, Jennings S, Ament R, Cuelho E (2017) Evaluation of effectiveness and cost-benefits of woolen roadside reclamation products final report prepared for the state of montana department of transportation in cooperation.