Abstract

Agro textile is one of the twelve categories of technical textiles, including utilisation in primarily four sectors: agriculture, horticulture, forestry, and aquaculture. Agro textile is one of the twelve categories of technical textiles, including utilisation in primarily four sectors: agriculture, horticulture, forestry, and aquaculture.

Keywords: Agro textile; Technical textiles; Natural fibres; Synthetic fibres

Introduction

Agriculture has been one of society’s most primitive professions and is still a significant sector on a global scale. Agricultural production needs to be significantly increased to fulfil the future food demands of increasing animal production and an expanding human population. Although agricultural practices have a long history of using traditional textile materials, it has broadened boundaries and begun using unconventional textiles known as technical textiles in this era of modernity and great technological breakthroughs. Agro textile is one of the twelve categories of technical textiles, including utilisation in primarily four sectors: agriculture, horticulture, forestry, and aquaculture. It minimizes the potentially harmful effects of environmental and climatic conditions on crop production and cattle breeding, controls the nutrients plants consume, and aids in the processing and post-harvest processes [1].

Agro textiles are incredibly versatile and cost-effective materials, having a market size predicted to expand from a value of $8.9 billion in 2020 to $12.4 billion by 2025 at a CAGR of 6.9%, their worldwide significance can be enormous. The market is predicted to grow by 8 to 10% annually in developing countries like China, India, and Brazil. Asia accounts for over 60% of the total market volume and 55% of the total market value. This category includes a wide range of products such as nets, fishing lines, shade cloth, ropes, mulch mats, woven and nonwoven crop covers, bird protection nets, anti-hail nets, and so on. Fishing nets account for the largest share of all agro-textile use. It is anticipated that other agro-textile product categories, such as shade nets, mulch mats, bird nets, and hailstorm nets, will also experience considerable growth.

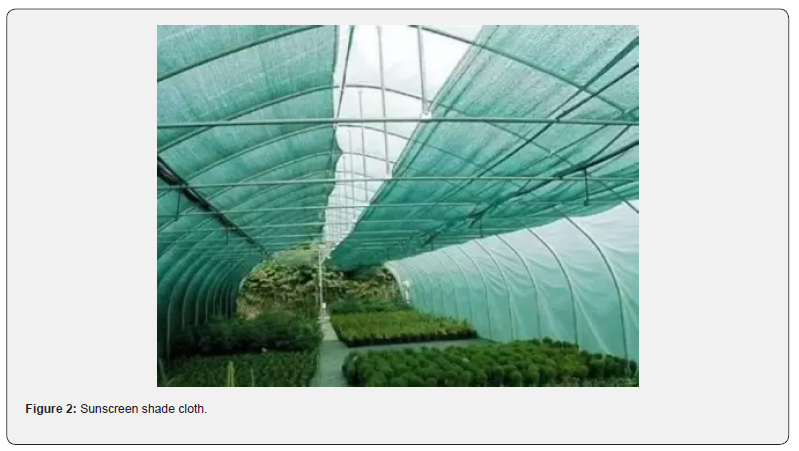

In the modern era of agriculture, the involvement of agro textiles is crucial. Due to increasing production and lowering the demand for chemicals, these textiles are profitably propelling the industry. Agro textiles prevent the soil from drying out, increase crop yield, and protect farmers from harmful pesticides. They also provide thermal protection against ultraviolet rays and are used for shade netting and thermal screens, saving up to 40% of energy in heating greenhouses. The use of agro textiles also prevents staining and improves the uniformity of colour. Because of its unique qualities, horticulture generates and dynamises employment crucial for local economies [2]. A few examples of agro textiles are shown in figure 1-4.

Essential Characteristics Needed for Agro-Textiles

Agrotextiles must have adequate tensile strength, sufficient permeability, and no significant degradation due to climatic extremes to be used for most end purposes. The type and circumstances of their manufacture and the fibres from which they are made affect these qualities. Agro textiles are placed over the cultivated areas right away after sowing or planting because they are flexible to adopt the contour of the plant and resistant to solar radiation. For applications such as agro-textiles, developments must be able to tolerate solar radiation with fluctuating ambient temperature; weather resistance; protection from climatic changes and their effect; protection from wind; and the establishment of a microclimate between the ground and the textile material, which results in the balance of temperature and humidity. The temperature rises in the root area concurrently. This results in earlier harvests; microorganism resistance - to safeguard the products and prevent infections; and should be biodegradable after their life to prevent soil and environment pollution [3].

Natural polymers have a higher capacity to hold onto water, lessen evaporation, and keep the soil from drying up than synthetic ones, but they have a shorter service life. This is accomplished by using fibre mats by adding superabsorbent so they can drench water. storage that requires less space; ease of transport; reduced need for fertilisers, pesticides, adequate stiffness and flexibility; which prevents soil contamination. The fabric construction should be made to withstand certain wear and strain, and the weight is expected to be light [4].

Natural Fibres and their Application in Agro-Textiles

Jute and coir are two natural fibers with a wide range of uses and carry huge potential in agro textiles. Jute is used for soil conservation and to reduce nutrient loss, as a nursery seed-bed cover, weed management, agro-mulching, afforestation in semiarid zones, sleeves for the growth of saplings, and wrapping or covering of plants. Mulch mats made from jute, wool, or coir nonwoven fabrics suppress weed growth in horticulture applications. Jute sleeves are used to grow seedlings and saplings in the nursery. Jute-based woven and braided sapling bags can regulate air and water circulation inside the sleeves, stimulating plant growth. Agro bags made from jute have been used for over two centuries to pack agricultural commodities like grains, sugar, spices, vegetables, etc [5].

Coir is a biodegradable organic fiber obtained from the husks of a coconut, and it is much more advantageous in different applications for agricultural textiles. Coir is versatile, hard, and has the greatest tearing strength of all-natural fibers, even when wet. Coir is used for erosion control, reinforcement, and stabilization of soil and is naturally resistant to rot, moulds, and moisture. Nonwoven coir is used to control erosion, condition soil, basket liners, mulch mats, plant cultivation mats, roof green applications, portable lawns, instant lawns, etc. Coir is also used for coco logs and beds for shore protection and stream banks [6].

Fibres such as wool, sisal, and hemp are also used in agro textiles. Wool offers better moisture resistance than polypropylene/ polyethylene and can minimise seedling damage from ground frost, allowing for earlier planting and a longer growing season. Unlike black plastic, wool maintains the soil temperature and does not create a wind tunnel effect, which dries out the soil. For tying, baler twines made of sisal and hemp fibres are used in grape yards. These twines are strong threads of two or three smaller threads or strands twisted together and are mostly used for crop wrapping. This is also employed in tomato plantations and can hold heavy fruits and vegetables on their stems or branches [7].

Synthetic Fibers and their Application in Argo-Textiles

Synthetic fibres are widely used in agro-textile production due to their durability, strength, and resistance to UV radiation. Shade nets are utilized to shield plants from overheating and UV rays. These nets are primarily formed from polyethylene fabrics or monofilaments and are woven or knitted. Shade nets come in various colors, including white, black, dark green, pale green, and green, and provide shade percentages ranging from 25% to 90%. They are lightweight and resistant to strong winds.

Crop/Antifrost covers are lightweight, breathable textiles that reduce heat and moisture loss, keep crops warm and well, and are wind resistant. Nonwoven spun bonded mesh fabric and UV-resistant polypropylene fleece are commonly used to make these covers. Windshields protect crops against high-velocity wind damage and help to regulate temperature by preventing wind-induced cooling. These shields are typically warp-knitted using high-density polypropylene monofilament or tape yarns. Windshields can have big or small apertures according to the wind protection needed, keeping branches from breaking, fruits from falling prematurely, and undesired harm to leaves and flowers.

Harvesting nets, primarily composed of polyethylene monofilaments and formed using warp knitting, gather the fruits that fall from trees. These nets streamline and rationalise the harvesting process, lowering cultivation costs by eliminating extra labour connected with harvesting. Bird protection nets are installed across trees and fields to keep birds from eating the fruits. These nets are typically manufactured using warp knitting, polypropylene monofilament, or polyethylene tape yarns. The mesh size for bird protection nets is large enough for bee movement, sunlight, and open-air circulation, preventing dangerous fungus from forming on the crop.

Anti-Hail nets protect crops from hail damage in hailstormprone and high-height locations. These nets are normally clear in colour and have a mesh size of 2*100 mm, allowing crops to get an acceptable amount of shadow (13% to 30%). UV-stabilised and constructed by weaving high-density polyethylene (HDPE), the anti-hail nets are lightweight, flexible, and easy to spread, with a simple support structure [8].

Future Prospects

The development of efficient agriculture, sometimes known as protected farming by controlling the environment, has expanded far beyond agricultural irrigation and water management. People’s incapacity to anticipate and control the weather continues. This is accompanied by an increasing population, which includes an increasing number of affluent and demanding people who expect better. From the literature, it can be rationalised that the use of synthetic fibers in agro textiles has immensely increased as compared to natural fibers. Although synthetic fibre can play a major role in making knitted and woven agro textiles such as mesh and nets, non-woven can be specifically preferred for making mulch and seed beds. Further, there should be more opportunities and research to use agro textiles because many nations’ economies rely heavily on agriculture. Land, water, energy, mineral nutrients, and the need for enhanced resource management are all factors to consider. As a result, it is expected that the size and spread of protected farming will continue to expand worldwide, with agro textiles serving as a catalyst.

References

- Palamutcu S and Devrent N (2017) Tehnical textiles for agricultural applications. Int Interdiscip J Sci Res.

- Kellie G (2016) Advances in Technical Nonwovens: Developments in nonwovens as agrotextiles, Woodhead Publishing, pp. 365-384.

- Subramanian S and Kannan M (2005) Another dimension to technical applications agro-textiles. Technical Textiles International 14(8): 25-27.

- Ajmeri J, Ajmeri C (2018) Developments in nonwovens as agrotextiles. Advances in Technical Nonwovens.

- Debnath S (2014) Jute-Based Sustainable Agrotextiles, their Properties and Case Studies. Roadmap to Sustainable Textiles & Clothing 327-355.

- Palash P, Debiprasad G (2011) Coir fibre and its Application in Geotextiles. Indian Textile Journal 121(6): 61-67.

- Maity S, Singha K, Prasad GD, Palash P, Singha M (2016) A Review on Nonwovens: Manufacturing, Properties and Applications, Journal of Natural Fibres 13(4): 383-396.

- Max J, Schurr U, Tantau J, Mutwiwa U, Hofmann T, et al. (2012) Greenhouse Cover Technology. Hortic Rev 40(1): 259-396.