Assessment of Drying Rate, Moisture Management & Comfort Properties of Fabrics for Sport Application

Mayur Basuk1*, Shishir Tyagi1 and RV Adivarekar2

1Wool Research Association - Centre of Excellence for Sportech, India

2Department of Fibers and Textile Processing Technology, Institute of Chemical Technology, India

Submission: March 10, 2023; Published: April 04, 2023

*Corresponding author: Mayur Basuk, Wool Research Association - Centre of Excellence for Sportech, Thane, India

How to cite this article: Mayur B, Shishir Tyagi, RV Adivarekar. Assessment of Drying Rate, Moisture Management & Comfort Properties of Fabrics for Sport Application. Curr Trends Fashion Technol Textile Eng. 2023; 8(3): 555736. DOI: 10.19080/CTFTTE.2023.08.555736

Abstract

The effect of different fiber blends in different composition on thermo- physiological comfort properties such as moisture management properties and heat flux or thermal conductivity (qmax) values are assessed. The thermo- physiological comfort properties of developed knitted fabrics (sportswear), composed of 100% polyester, Poly/ Excel, Poly/ Modal in different fiber blends, have been investigated. The moisture management properties are assessed by using the moisture management tester, and the feeling of coldness or warmth is assessed by measuring qmax value on KES-F7 Thermo labo II. Blending polyester fiber with modal & Excel has improved moisture management properties and quick drying rate of the fabrics in comparison to 100% polyester fabric. Peak Heat Flux study (qmax) also indicates that polyester/excel and polyester/modal blend fabrics retain less heat and thus feel cooler as compared to 100% polyester fabric.

Keywords: Thermo- physiological comfort properties; Excel; Modal; Moisture management testing (MMT); Heat flux; Polyester; Sportswear

Introduction

There has been enormous market growth for sportswear over the last 20years. Sports Apparel Market was valued at USD 171.25 Billion in 2021, and it is expected to reach USD 287.70 Billion by 2029, exhibiting a CAGR of 6.7% during the forecast period (2022-2029). The sportswear market comprises around 45% of the global sports equipment, sport apparel and footwear market. The sportswear categories account for a sales value of approximately US $265 billion in 2015 as reported in Euromonitor International (2016). Sports apparel, often known as sportswear or activewear, is clothing worn for physical activity or sport. For practical, comfort, or safety reasons, most sports and physical activities necessitate the use of sport-specific apparel. Sport-specific attire includes tracksuits, shorts, T-shirts, and polo shirts. Specialized gear includes swimsuits (for swimming), wet suits (for diving or surfing), ski suits (for skiing), and leotards (for gymnastics). Sports footwear includes trainers, football boots, riding boots, and ice skates. Sportswear is sometimes used as casual fashion apparel. As per the market demand, sportswear can be categorized into four groups, viz performance sportswear, basic sportswear, sports leisurewear, and sports- fashion clothing. Performance sportswear is highly technical- oriented clothing which enhances the performance with special functionality. It is produced in lowest volume and highest price range, whereas basic sportswear is cheaper and more stylish while retaining as many of the material attributes as possible. Sports leisurewear is replica of performance sportswear, worn at home and is sold in higher volume at much smaller price.

In recent years, development in active sportswear fabrics has been progressing to perform high functions and to achieve comfort. Comfort may be defined as a pleasant state of psychological, physiological and physical harmony between a human being and the environment. Wear comfort of active sportswear can be divided into four different aspects, namely Thermo physiological comfort, Sensorial/Tactile comfort, Mobility/Dexterity comfort, psychological comfort [1,2]. Thermo physiological wear comfort concerns the heat and moisture transport properties of clothing and the way it helps the clothing to maintain the heat balance of the body during various levels of activity [3]. The sports and leisure wear exert a barrier for efficient transfer of excess heat resulting in a rise in core body temperature and skin temperature greater than 37°C which increases sweating [4]. Clothing materials should thus have a high moisture retention capacity and high moisture transportation properties to maintain constant temperature humidity between skin and fabric. This is based on the fact that the moist fibers can act as a heat reservoir [5]. During sport activity the human body generates heat quickly due to faster metabolism then the body’s cooling mechanism attempts to dissipate this extra heat by producing perspiration. Perspiration should be readily taken away from the skin to the outer atmosphere before it accumulates on skin for maintaining cool and dry condition to make the sport person comfortable and to enhance their performance during sport activity [6,7].

Moisture management is of critical importance in Active sportswear fabrics in respect of thermo-physical comfort. Therefore, it is essential to increase the hydrophilicity of Polyester. In Moisture management fabrics, the body perspiration is transported away from the skin to the outer surface of fabric where it can evaporate quickly in order to accomplishing the consumer satisfaction of comfort [8]. To achieve such moisture management, the structural design and quality of fibers are modified so that the textile products can have good performance in absorbing, transporting, and dissipating moisture [9,10].

Knitted fabrics are widely used in sportswear due to their excellent stretch and recovery, porosity, air permeability, softness and warmth. In last few years knitted fabrics are gaining interest due to its simple production technique, low cost, high level of clothing comfort and wide range.11 it also offers good freedom of movement, shape retention and tailored fit. With the possibility of numerous combinations of fabric construction and yarns used, knitted fabric is considered ideal technique for sportswear development such as t-shirts [11,12].

Materials and Methods

Materials

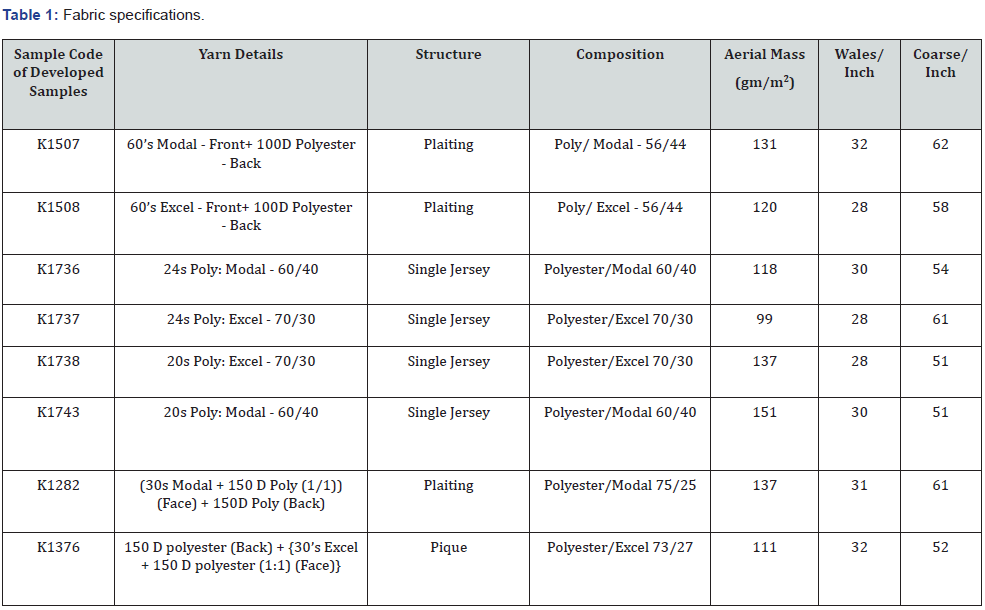

Polyester (100 den, 150 den Micro PET filament), modal (20s, 24s, 30s, 60s Ne), and excel (20s, 24s, 30s, 60s Ne) were combined in different proportions for fabric development. Modal and Excel fibre used in this study were procured from birla Cellulose, Aditya Birla Group. Polyester filaments used for the study were obtained from Reliance Industries. Different knitted structured fabric developed on circular knitting machine such as: Plaiting, single jersey, pique composed of fibers mentioned above in different composition were developed at Textile Research & Application Development Centre (TRADC), Birla Cellulose, Grasim Industries Ltd. All testing was carried out under environmentally controlled conditions (21±1°C and 65±2% RH) according to ASTM D 1776. The moisture management properties of all fabrics were tested and evaluated by using the Moisture Management Tester (MMT) according to the AATCC Test Method 195-2009 and feeling of coldness or warmth was assessed by measuring ‘qmax’ value (peak heat flux) on KES-F7 Thermo labo II at COE-Sportech Laboratory of Wool Research Association, Thane. The composition and physical properties of developed fabrics are presented in table 1.

Peak heat flux (qmax) measurement

The sensation of coldness or warmth when skin touches a fabric is referred to as the “coldness and warmth feeling.” The feeling of coldness or warmth will vary depending on the amount of heat transferred from the skin to the fabric. This device measures that feeling by evaluating the “qmax” value (peak heat flux). Qmax was measured on KES-F7 (Thermolabo II). The Thermolabo II consists of (i) a guarded hot plate (BT-Box) with 5cm×5cm area, (ii) T-box which is essentially a copper plate with a known thermal capacity insulated on all sides except front face, and (iii) water box which can be maintained at any temperature by circulating water through it.

Qmax can be measured both with and without constant temperature base. The present study employed insulated condition for measuring qmax. The T-box was heated to about 30°C by keeping it over hot BT-Box. The T-box was then quickly placed over the fabric, which was kept over a constant temperature of 20°C. The maximum heat flux flowing between the T-Box and the fabric surface was detected by the electronics of the instrument [13]. The experiment was carried out in a controlled atmosphere (65±2% RH and 27±1°C (temp).

Drying rate

The Drying rate tester (AATCC Test Method 201 Drying Rate of Fabrics: Heated Plate Method) is capable of measuring the rate at which a textile specimen dries after being exposed to water drying. The specimen is placed on a heated plate, which is maintained at 37 degrees Celsius to simulate the temperature at which human skin begins to perspire. Water is dosed on to the heated plate underneath the specimen to simulate perspiration.

The temperature drops when the specimen is wet and as the specimen dries, the temperature gradually increases. The machine software records this change in temperature and automatically calculates the drying time and rate of the tested specimen. Quick drying is an important attribute of textiles worn next to the skin, during sporting activities where the skin is likely to perspire. Without this characteristic, perspiration does not easily evaporate from the garment, which can leave a wearer feeling uncomfortable. Drying rate tester replicates the conditions of use in order to verify that quick-drying fabrics are performing effectively. This method is used in the development of quick-drying fabrics and garments such as base layer garments, football kits, running gear, gym gear, socks and footwear, and is important in other performance fabrics such as those used in uniforms for military and emergency services personnel.

Moisture management properties

Fabric liquid moisture transport properties in multidimensions, called moisture management properties significantly influence human perceptions of moisture sensation. Moisture management tester (MMT), developed by SDL Atlas to evaluate textile moisture management properties, was used. This method can be used to quantitatively measure liquid moisture transfer in one step in a fabric in multiple directions. Moisture spreads on both surfaces of the fabric and transfers from one surface to the opposite. Here, ten indices are introduced to characterize the liquid moisture management properties of fabric. Electrical conductivity changes are measured as the test solution migrates across the top of, though and across the bottom of the test specimen. Factors affecting this movement include fabric water repellency, water resistance, and water absorption, along with the fiber and yarn wicking properties. Perspiration is mimicked with TM 195. The results obtained with this test method are based on water resistance, water repellency and water absorption characteristics of the fabric structure, including the fabrics’ geometric and internal structure and the wicking characteristics of its fibers and yarns [14].

Ten indices of the MMT, used to characterize the moisture management properties of a fabric, are as mentioned below:

(i) Wetting time top (WTt)

(ii) Wetting time bottom (WTb)

(iii) Top absorption rate (MARt)

(iv) Bottom absorption rate (MARb)

(v) Top maximum wetted radius (MWRt)

(vi) Bottom maximum wetted radius (MWRb)

(vii) Top spreading speed (SSt)

(viii) Bottom spreading speed (SSb)

(ix) Accumulative one-way transport capacity (OWTC)

(x) Overall moisture management capability (OMMC)

The OWTC is the difference in accumulative moisture content between the two surfaces of the fabric. The OWTC reflects the oneway liquid transport capacity from the top (inner) surface to the bottom (outer) surface of the fabric [15]. The OMMC is an index indicating the overall capacity of the fabric to manage the transport of liquid moisture, which includes following three aspects:

(i) Average moisture absorption rate at the bottom surface

(ii) One-way liquid transport capacity

(iii) Maximum moisture spreading speed on the bottom surface

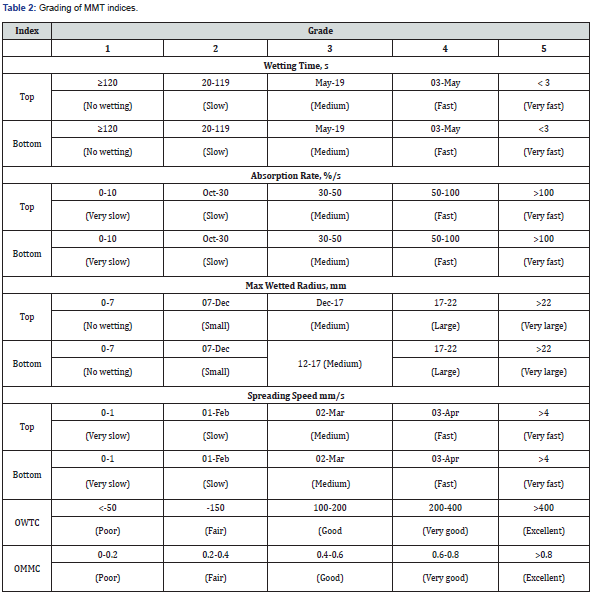

According to AATCC Test Method 195-2009, the indices are graded and converted from value to grade based on a five-grade scale (1-5): 1–poor, 2–fair, 3– good, 4–very good and 5– excellent. Table 2 shows the range of values converted into grades.

Results and Discussion

qmax Measurement

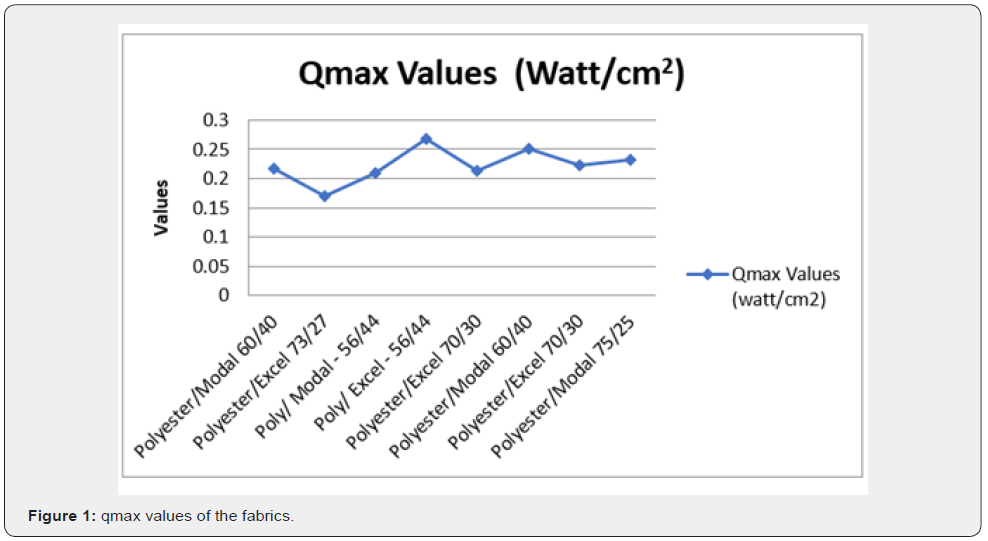

qmax is the feeling of coolness or warmth. It means the feeling we get when human skin touches an object. It is measured as the maximum amount of heat flow between the body and the fabric (Watt/m2). The higher the value, the cooler we feel.

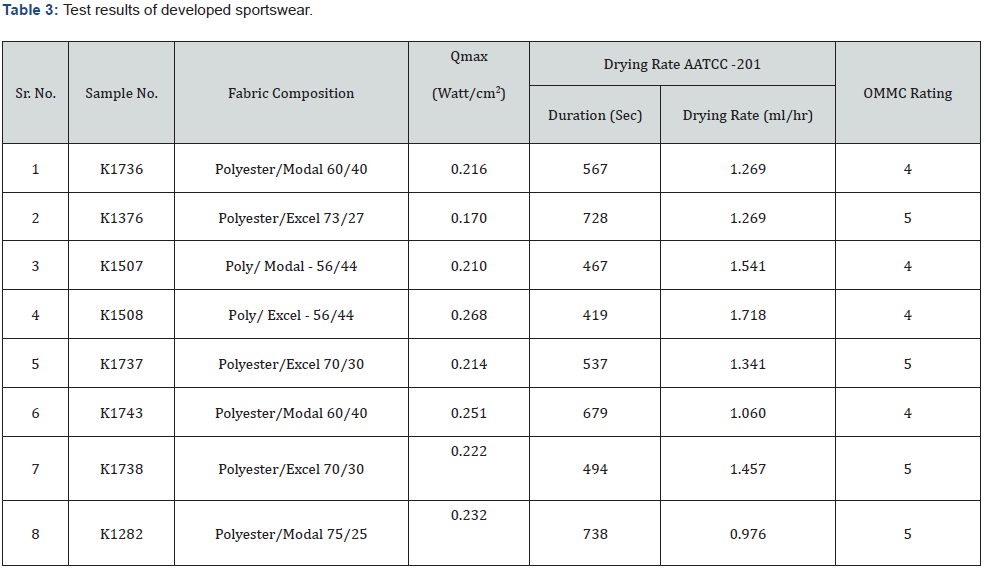

Figure 1 indicates qmax values for the fabric’s samples. Table 3 indicates qmax values for eight fabrics under study. The result obtained indicates that Pique Structure of Polyester blended with Excel in blend ratio of 73/27 gives the lowest value of qmax out of all 08 fabrics developed which corresponding that that less amount of heat transferred from the skin to the fabric compare to other fabrics. In the case of Plaiting Structure of Polyester blended with Excel and Modal, blend ratio of 56/44 Poly/Excel gives the highest value of qmax which corresponding that that less amount of heat transferred from the skin to the fabric compared to other fabrics. Polyester/Modal 60/40 give highest qmax values in single jersey knitted structure which is 0.251 watt/cm2 .

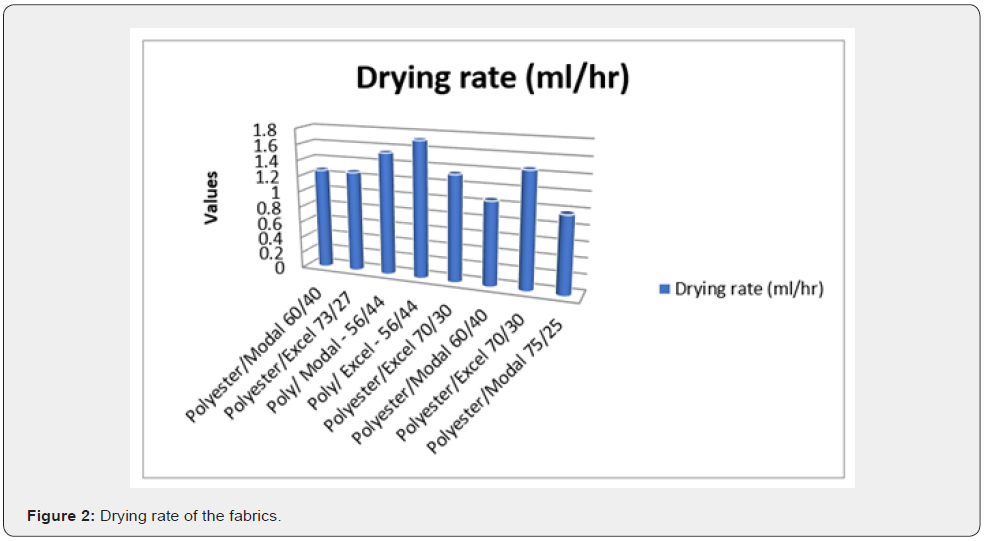

Drying rate

Figure 2 indicates the drying rate of the developed fabrics samples. Table 3 indicates that Poly/ Modal fabric blend ratio - 56/44, Poly/ Excel fabric blend ratio - 56/44 and Polyester/Excel fabric blend ratio 70/30 are having lesser drying time (sec) and better drying rate (ml/hr) among the others. Thus, these fabrics can be considered as quick dry fabrics. Plaiting Structure of Polyester blended with Modal & Excel, the blend ratio of 75/25 polyester with Modal fibers gives lowest drying rate among all developed fabrics. Among the developed single jersey knitted structures of Polyester blended with Modal & Excel fibers, Polyester/Excel 70/30 gives the highest value of drying rate. In case of Pique Structure of Polyester blended with Excel in blend ratio of 73/27, the Drying rate found to be equal to Polyester/ Modal 60/40 blend ratio in single jersey structure.

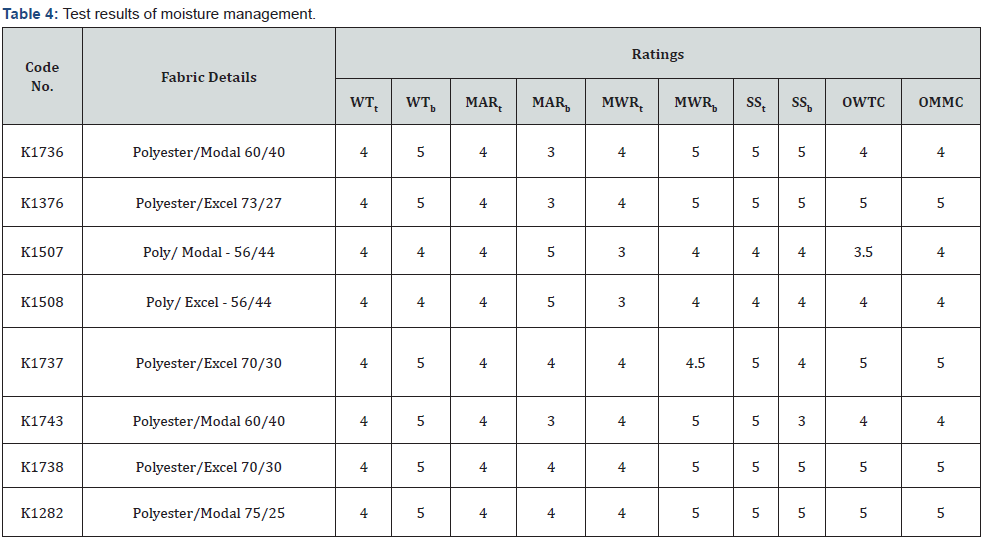

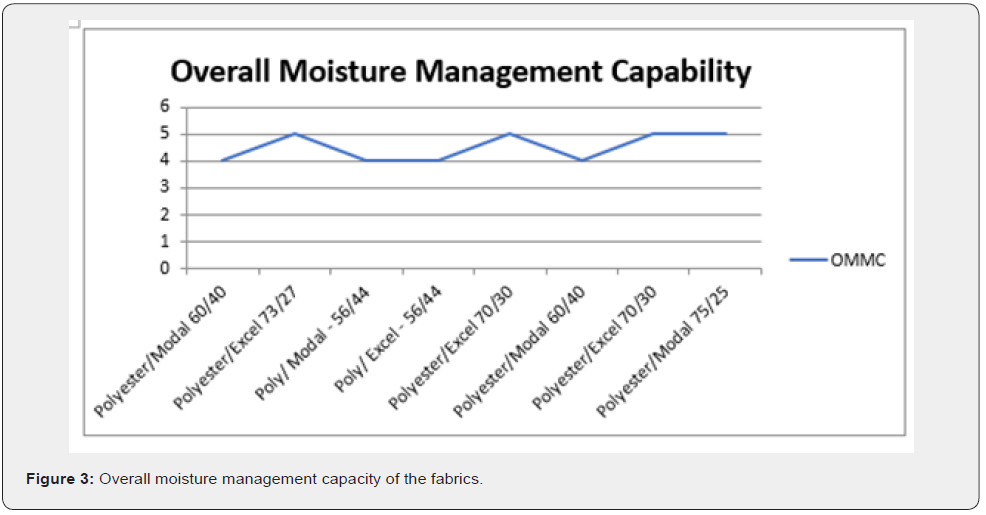

Overall moisture management capability

Table 3 indicates that all the eight developed fabrics have good to excellent overall moisture management capability and qualifies to call as moisture management fabrics & table 4 indicates the test results of moisture management fabrics. Figure 3 indicates the overall moisture management capability of fabrics.

Comparison between single jersey structures of Polyester blended with Modal & Excel demonstrates that blending polyester with such fiber improved OMMC significantly in 70/30 blend ratio of polyester with either Modal or Excel fibers. This indicates that blending modal or excel fibers with polyester makes it more suitable for sportswear application without using any hydrophilic chemical finishes. In case of Plaiting Structure of Polyester blended with Modal & Excel, the blend ratio of 75/25 polyester with Modal fibers gives higher Overall Moisture Management Capability while blend ratio of polyester with either Modal or excel fibers in the proportion of 56/44 gives lower OMMC values. In the case of Pique Structure of Polyester blended with Excel in blend ratio of 73/27, the OMMC values were found to be increased.

Conclusion

Polyester has outstanding dimensional stability and excellence resistance to dirt, alkalies, mold and most of the organic solvent and also has excellent heat resistance but is essentially hydrophobic fiber and does not absorb moisture therefore Polyester to be used in sportswear need to be treated with chemicals to increase its moisture management properties. Polyester has high initial wetting time and low spreading speed therefore it can be used effectively as a base fabric in two layer sportswear where it can transfer moisture quickly to outer hydrophilic layer. Out of 08 fabrics selected in the present study, Polyester/ Excel in the blend ratio of 56/44 among plaiting structure fabrics gives a higher Drying rate & higher Peak heat flux (qmax) value i.e., more coolness and also gives good moisture management. Polyester/ Excel in the blend ratio of 70/30 also gives higher Drying rate & Good Peak heat flux (qmax) value i.e., more coolness and also gives excellent moisture management among single jersey structure and may be suitable blend composition for designing in sportswear application. Therefore, Polyester if blended with Excel can be used effectively for sportswear applications.

Acknowledgement

The authors of this article are thankful to the Management of Wool Research Association & Institute of Chemical Technology for their continuous support, valuable guidance & input. The authors gratefully acknowledge the R & D Project support received from Ministry of Textiles, Govt. of India & Textile Research & Application Development Centre (TRADC), Birla Cellulose, India.

References

- Kothari VK (2006) Theermo-physiological comfort characteristics and blended yarn woven fabrics. Indian J Fibres Text Res 31: 177.

- Nelson Raj AE, Yamunadevi S (2016) Application of textile fibres for technical and performance enhancements in sports. Int J Multidiscip Res Dev 3(12): 40-45.

- Bhatia D, Malhotra U (2016) Thermophysiological Wear Comfort of Clothing: An Overview. J Textile Sci Eng 6(2): 1.

- Stoffberg ME, Hunter L, Botha A (2015) The Effect of Fabric Structural Parameters and Fiber Type on the Comfort-Related Properties of Commercial Apparel Fabrics. J Nat Fibers 12: 505-517.

- Okubayashi S, Griesser U, Bechtold T (2004) A kinetic study of moisture sorption and desorption on lyocell fibers. Carbohydr Polym 58: 293-299.

- Gorji M, Bagherzadeh (2016) Moisture management behaviors of high wicking fabrics composed of Profiled Fiber. Indian J Fibres Text Res 41: 318-324.

- Sharma N, Kumar P, Bhatia D, Sinha SK (2015) J Inst Eng India Ser E.

- Duru S, Candan C (2013) Effect of repeated laundering on wicking and drying properties of fabrics of seamless garments. Text Res J 83 (6): 591-605

- Sarkar M, Fan J, Szeto Y, Tao X (2009) Biomimetics of plant structure in textile fabrics for the improvement of water transport properties. Textile Res J 79: 657-668.

- Su, Fang J, Chen X, Wu W (2007) Moisture absorption and release of profiled Polyester and cotton composite knitted fabrics, Textile Res J 77(10): 764-769.

- Mahish S S, Patra A K, Thakur R (2012) Indian J Fibres Text Res 37: 231.

- Nazir A, Hussain T, Ahmad F, Faheem S (2014) Effect of Knitting Parameters on Moisture Management and Air Permeability of Interlock Fabrics. AUTEX Res J 14(1): 39.

- (2002) KES-F7 Thermolabo II Instruction Manual (Kato Tech Co. Ltd, Kyoto 601, Japan).

- AATCC Test Method 195-009 (2009) Liquid Moisture management Properties of Textile Fabrics.

- Mayur B, Mrinal C, Saptarshi M, R Adivarekar (2018) Moisture Management Properties of Textiles and Its Evaluation. Curr Trends Fashion Technol Textile Eng 3(3): 555611.