Technological Features of Production of Synthetic Juniper Fiber

Inga Lyashenko* and Arta Viluma-Gudmona

Scientific Research Laboratory of Bio textile Materials, Riga Technical University, Latvia

Submission: February 12, 2018; Published: March 08, 2018

*Corresponding author: Inga Lyashenko, Scientific Research Laboratory of Bio textile Materials, Riga Technical University, LV-1007, Pulka Str. 3/3, Riga, Latvia, Tel: +371 29123931/+ 371 67089631; Email: Inga.Lasenko@rtu.lv

How to cite this article: Inga L, Arta V-G . Technological Features of Production of Synthetic Juniper Fiber. Curr Trends Fashion Technol Textile Eng. 2018; 3(3): 555615. DOI: 10.19080/CTFTTE.2018.03.555615

Abstract

According to the literature Juniper (Juníperus commúnis) as possible implant material has proved biocompatibility with the animal muscle tissue and morphology of its trunk is similar to the morphology of bone, namely the presence of cross-perforations in the juniper allows capillaries to grow through, so usual rejection of the implantable material does not occur. This study shows developed synthetic polypropylene fibers as biomimetics (repeating structure) of juniper fiber and investigation of its mechanical properties. Morphology of Juniper was studied by field emission scanning electron microscope; cross-perforation of fibers was carried out with a focused laser beam pulses with a diameter of 5-10μm synchronously scanning the fiber in the longitudinal direction and perforating with a step 150-200μm. The optimal operating mode was identified: the frequency, laser pulse duration, power of UV pulse and an optical system for tracking the position of the fiber was developed, taking into account the slack of textile fiber. After cross-perforation textile fibers was treated with juniper 5% water solution to provide antiseptic effect. In order to determine the ability of a material to perceive the load, which appears during the operation of the material in the human body, theoretical and experimental research of fiber behavior in the axial deformation was performed, which show that the strength of filaments weakened by cross-perforations is only 6-11% less than of fibers without perforations. Obtained polypropylene biomimetic material conventionally repeating the structure of the juniper probably will improve biomechanical properties and can be standardized for future widespread use in biomaterials.

Keywords: Synthetic juniper fiber; Biomimetic; Juníperus commúnis; Cupressaceae; Nanocomposite

Abbreviations: PP: Polypropylene; SE: Secondary Electron; LVSTD: Low Vacuum Secondary Electron; TE: Transmission Electron; EDS: Energy Dispersive X-ray; MFA: Micro Fibrill Angle

Introduction

Characterization of juniper wood

Juniper (Juniperus communis) is a slowly growing softwood species that has unusually high elasticity, but it also is dense durable, strong and naturally impregnated with essential oil that prevents infections [1-3]. The generic name is derived from Juniperus, Celtic word jeneprus - prickly, the Latin word communis meaning common - it is pine evergreen dioecious, rarely monoecious shrub 1-3m (or a tree with branched stem up to 12m in height), the family Cupressaceae. Family Juniperus includes 60 species occurring mostly in the mountains of the temperate zone of the Northern Hemisphere. Juniperus communis wood is dense, durable, and strong and has naturally impregnated essential oils that display antiseptic properties. Juniperus communis wood implants contain an effective formulation of oil that prevents infection. Toxicity studies showed that rats tolerated the oil well except at high doses that exceeded the oil content typically contained in a wood implant. The oil made available from an implanted wood would be initially limited to the oil in the wood cells on the outer layer of the wood. Rabbit studies of wood implants shaped as femoral components indicated that the wood was well tolerated by the body and was surrounded by bone tissue. Bone growth occurred within the open pores of the wood surface and holes machined in the wood to improve the integration [2]. The essential oil, consisting mainly of cadinene, camphene, etc., is found in all plant organs: in the fruit, stems, pine needles, bark. In addition, the fruit contains up to 40% invert sugar, about 9.5% of resin. The bark contains up to 8% tannins; needles - 266mg /% ascorbic acid. Berries, other than essential oils, contain sugars, resins, pigments, fatty oil, organic acids, malic, formic and acetic acid, tannins and minerals (manganese, iron, copper and aluminum) [4]. The plant extracts from juniper has an influence on the membrane integrity, metabolic activity and amount of protein p53 which is one of the key regulator of apoptosis in SH-SY5Y neuroblastoma cells. Juniper extract is effective in increasing the amount of p53 amongst the tested plant extracts, and it also showed significant cytotoxic effects in SH-SY5Y cells. Since the juniper extract potently decreased the cell viability and increased the amount of p53, further studies are in progress to investigate the role of the juniper extract in the cell death [5].

Basically, the wood is natural fibre composite, or nanocomposite, that has been used successfully by humankind in load bearing structural applications [4]. In vivo studies of juniper wood implants shaped as femoral components indicated that the wood was well tolerated by the body and was surrounded by bone tissue [2]. Juniper in fact resembles the compression wood of spruce in its mechanical properties; its density is 50% higher than density of normal spruce wood, and it has the high Micro Fibrill Angle (MFA). The composition of juniper resembles spruce compression wood, but the lignin and hemicellulose contents are higher in juniper and lower than spruce compression wood [3]. Wood is one of the natural materials that inspired mankind very early to imitate some of its features to develop new «intelligent» artificial materials. The properties of wood are optimized in various respects and in various areas. It exhibits, for example, excellent mechanical properties together with low density, and both are determined by its structural design [6]. For implantation of wood implants are used heat-treated wood. The natural channel structure of wood served as a porous scaffold, allowing host bone growth as small islets into the wood implants. The other properties of heat-treated wood, such as bioactivity, good handling properties, and sufficient biomechanical properties, might be additional favorable factors for the application of wood as a natural composite material for bone and cartilage repair. At the interface of the surfaces of wood and living bone, bonding occurred. The Chemical Interface Model for bonding bone to wood consists of the reactive ions, such as hydroxyl groups -OH, and covalent bonding as well as hydrogen bonding, which originate from both wood and bone. The bone tissue trauma, with its reactive Ca2+ and PO43- ions, proteins, and collagen, available for interaction at ionic and nanolevel, are associated with the complicated chemistry in the cellular response of the early bone healing process. It was concluded that heat-treated wood acted like a porous biomaterial scaffold, allowing on growth and in growth of bone and cartilage differentiation on its surface, and demonstrating osteoconductive contact, bonding at the interface [7].

Despite all mentioned above the wide application of juniper wood as biomaterial is limited because it is difficult to standardize. In this paper study of juniper morphology generated our idea of creating biomimetic, which reminiscent juniper features for use in the manufacturing surgical meshes.

Surgical meshes

Surgical mesh is a woven fabric which usually made of Gore-Tex®, Teflon®, polypropylene (PP, Prolene®) or some other polymers, although a titanium mesh used for chest wall reconstruction, strengthening tissues; provide support for internal organs, and to treat surgical or traumatic wounds. The most common types of surgical mesh are hernia mesh, stress urinary incontinence slings and mesh for treating prolapse. The Polypropylene Mesh and Polytetrafluoroethylene Mesh fabrics are used to manufacture such devices as hernia mesh, stress urinary incontinence slings, and vaginal prolapse suspenders. The main function of synthetic meshes is to provide either mechanical closure to the defect (sublay technique) and/or induce a strong scar tissue that incorporates the mesh within the surrounding environment. Material design parameters such as chemical composition, weight, pore size, and filament structure represent critical parameters employed in surgical mesh design. The right balance between composition and material construction of surgical meshes can lead to similar performance in the field [8].

Over the past decades, stabilization of abdominal wall defects by implantation of surgical meshes has become routine in hernia surgery. However, because surgical meshes are composed of synthetic materials, they induce a foreign body reaction after implantation. Surgical meshes induce chronic pain, infection, adhesions, seroma, and fistula formation and a variety of biological tissue responses such as the activation and recruitment of inflammatory cells to the site of implantation, the development of new blood vessels, and the formation of granulation tissue that finally incorporates the implanted biomaterial into the surrounding host tissue [9]. Therefore, the development of surgical meshes, which guarantee an optimal biocompatibility and incorporation into the host tissue, represents one of the major challenges in modern hernia repair [10]. Huber A, et al. in 2012 performed a meta-analysis of 38 articles and divided surgical meshes into six different treatment groups depending on composition. A meta-analysis was performed to assess these outcomes in six different treatment groups depending on mesh composition: Polypropylene (PP), PP in combination with non absorbable polymers, PP in combination with absorbable polymers, non-PP polymers, non-PP in combination with absorbable polymers, and natural materials. The results support the general concept that meshes made from pure PP alone result in a more adverse host tissue response than composite or naturally occurring biomaterials, thus explaining the need for the development of alternative synthetic and biologic devices. These devices also provided a high level of mechanical stability resulting in a reduced level of adhesion formation and device shrinkage post application. Adhesion area, adhesion grade, vascularization, and the grade of inflammation were generally greater for PP. In conclusion, PP devices with an absorbable component elicit a more beneficial host response when compared with pure PP devices alone with respect to connective tissue adhesion and tissue inflammation while providing a high level of mechanical stability resulting in a reduced level of adhesion formation and device shrinkage post application [11].

Materials and Methods

Morphological examination of juniper root

The juniper wood (Juníperus commúnis) in this work was taken from a forest in Adazi Region, Latvia. Sample of root (length 20cm, thickness 1.5cm) was dug out then carefully washed with distilled water and dried in air at r.t. for 2 days. Morphological investigation and determination of chemical composition of juniper root was carried out by using field emission scanning electron microscope Mira/LMU (Tescan).

Cross perforation of polypropylene fibers

Polypropylene (PP) biotextile fibers 13 Tex were used, cross perforation performed with a Secondary Electron (SE), reflection electron (BSE), Low Vacuum Secondary Electron (LVSTD) and Transmission Electron (TE) detector, sample holder-cooler, Energy Dispersive X-ray (EDS) spectrometer. Electron accelerating voltage from 3 to 30kV and working distance - from 6 to15mm. Non-conducting juniper root sample was covered with the gold (15nm), using the plasma sputtering equipment K550X (Emitech). Cross-perforation of fibers was carried out with a focused laser beam pulses with a diameter of 5-10|/m synchronously scanning the fiber in the longitudinal direction and perforating with a step 150-200μm.

Mechanical properties of cross-perforated polypropylene fibers

Tensile strength determined by universal fibers testing machine ZwickBDO/FB020TN. Polypropylene 13 Tex fiber were used for comparing polypropylene 13Tex fibers weakened with 5-8μm cross-perforations. Examination of the samples were carried out according to the method LVS EN ISO 2062:2001 at the following geometry of fibers:

Di = 0.11mm - cross-sectional diameter of continuous filament (without cross-perforations);

Do = 0.005mm - cross-sectional diameter of the cross-perforations.

𝓁 = 250mm - operating length the fiber at which elongation of the fiber sample is fixed;

v = 250mm/min = const - rate of sample loading.

Results and Discussion

Morphological examination of juniper root

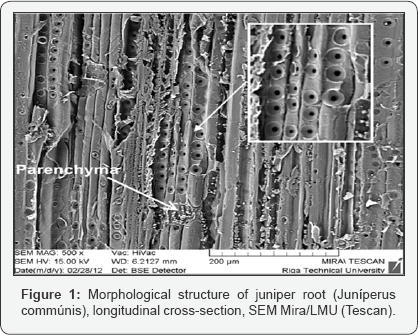

Figure 1 shows morphological structure of juniper root. In the structure of juniper root are clearly visible pores that often occur in the wood of pine trees and parenchymes -specific to vascular plants cells which supply plant with nutrients. It was confirmed by the analysis (SEM), as in parenchyma is present such chemical elements as C (77%), O (22%), Mg (0.23%), P (0.12%), Cl (0.09 %), K (0.20%), Ca (0.50%), etc.

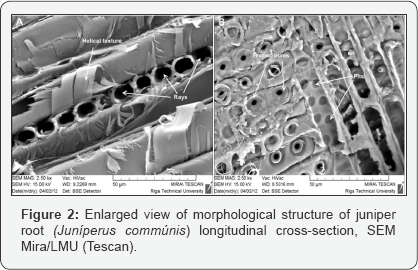

Figure 2 shows enlarged view of morphological structure of juniper. At higher magnification rays helical grooves or cavities indicating the MFA (determines elastic modulus) of the cell wall are clearly visible (Figure 2a). Pits and framed pores with membranes at Figure 2b, became the prototype for the creation of biomimetic, because these structural features of the Juniper root gives it an unusual elasticity.

Cross perforation of polypropylene fibers

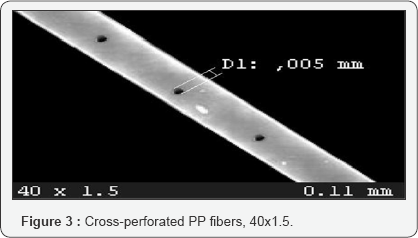

To create the new biomimetic material, was performed cross-perforation of polypropylene 13tex fibers. Figure 3 shows a segment of obtained polypropylene fiber with crossperforations with a diameter 5μm, which corresponds to the diameter of blood capillaries.

Cross-perforation of polypropylene fibers was carried out on the fiber fixed on a 3D scanning micro-manipulator desk so impulse laser beam (5-10μm) could focus on the fiber (space between cross-perforations 150-200μm). The complexity of this work was to synchronize the movement of laser pulses and micro-manipulator table. As a result it was identified the optimal operating mode: the frequency of the pulses (T=0.1 s), laser pulse duration (τ=1-10ms), and power of ultraviolet laser pulse (W= 1÷5mJ). We also developed an optical system for tracking the position of the fiber, taking into account the slack of textile fiber.

Experimental and theoretical determination of mechanical properties of cross-perforated polypropylene fibers

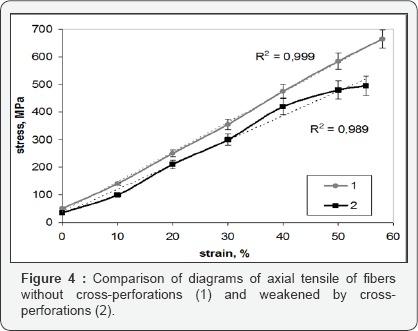

To determine the ability of a material to perceive the load, which will appear during the operation of the material in the human body after implantation, it was carried out experimental and theoretical research of fiber behavior in the axial strain. Experimentally determined mechanical properties of fibers were characterized by diagram of the axial tensile (stress - strain) (Figure 4).

As can be seen from given diagram, the difference in axial tensile between fibers weakened and none weakened by crossperforation is insignificant. This suggests that the modification of fiber's profile with cross-perforation in order to obtain a new biomaterial with better biocompability for surgical mesh production will not significantly decrease the mechanical properties of fibers.

Theoretically, strength and stiffness properties of developed material, as well as its service life determined by the relevant physical and mechanical properties and chemical structure of individual filaments of which are designed material. After analyzing the nature of work of the implantable material, both during and after implanting into the body, it is possible unambiguously conclude that the main component of the load, which treats each fiber, during the deformation when it's used in the body, is related only with axial filament elongation. In addition, the mechanical analysis of the behavior of this textile material as a construction in the body, taking into account the geometry and structure of this material, as well as the diameter, the geometry of the cross-perforations and structure of the material fibers, from which this material was developed, we can suggest that each fiber in the construction of material is resisting flexural loads and poorly resists torsion loads, and therefore does not transmit these loads on the structure of the material. Loading fibers with an axial tensile force, its major force and stiffness of features are:

a. Normal stresses in the material of fibers;

b. The stiffening feature of fiber associated with elongation (or axial deformation);

c. Behavior of the cross-perforations in the fiber, i.e., the nature of their" closing" related to really possible decreasing of its diameter.

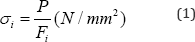

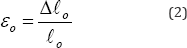

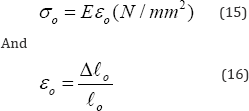

In theoretical and experimental analysis of fibers behavior in the axial tensile deformation using the methods of mechanics for deformed solids. Taking into account the chemical composition of the material, method of manufacturing of fibers and type of transferred load in the first approximation we assume that the material of the fibers is: a homogeneous, isotropic and elastic. Considering the possible load that can be transferred to the material from the organ in which this material is implanted, the deformation occurring in the material of the fiber with these loads can be considered as finite, but enough small. These assumptions are confirmed by experimental studies, which allows in the analysis of the stress-deformed state of fibers material to use methods of linear elasticity theory of deformed solid [12]. In this case, for the stress-deformed features of the material we have the following analytical expressions. Normal stresses a in the material of fiber which cross-section is not weakened by cross-perforations is calculated using the formula (1):

Where: P - axial tensile load (N), which perceives the fiber during loading; Fi - cross-sectional area (mm2) of fiber without cross-perforations, which is calculated using formula (2):

Where: Di - cross-sectional diameter of the continuous fiber which is not weakened by cross-perforations , mm.

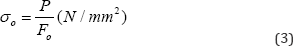

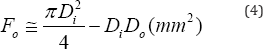

Where: Fo - cross-sectional area (mm2) of fiber with crossperforations, which is calculated using formula (4):

Where: Do - cross-sectional diameter of the continuous fiber which is weakened by cross-perforations, mm.

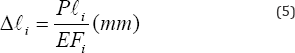

Elongation Δ𝓁i of the fiber's segment which is not weakened with cross-perforations during axial tension is calculated by the formula (5):

Where: 𝓁i- length of the fiber's segment, not weakened with cross-perforation during axial tension; E - the elastic (tensile) modulus (Young's modulus) of fiber's material, MPa.

Elongation Δ𝓁1 of the fiber's segment which is not weakened with cross-perforations during axial tension is calculated by the formula (6):

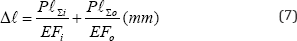

Combining equations (5) and (6) we obtain general equation (7) for calculation elongation of fibers with/without crossperforations:

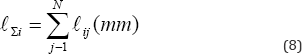

Where:𝓁Σi - the total length of fiber's segments without cross-perforations which perceive the axial tensile load, (mm), which is calculated using formula (8):

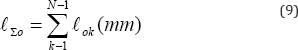

𝓁Σ0- the total length of fiber's segments with cross- perforations which perceive the axial tensile load, (mm), which is calculated using formula (9):

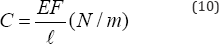

In the analysis of deformed state of the fiber common is used the stiffness or flexibility of the fiber’s material, which is calculated by the formula (10) [11]:

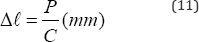

So, in general, when under the axial tensile, elongation of fibers Δ𝓁 , which is with/ without cross-perforations is calculated by the formula (11):

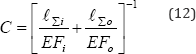

Where C - present stiffness of the fiber’s material, which taking into account equations (8 - 10) can be written as:

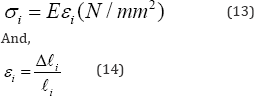

Knowing the elastic modulus of the material (E) an elongation at every fiber’s segment, normal stresses in the material of the fiber (1) and (2) can be written as: normal stress σi in the material fiber (1) which is not weakened by cross-perforations:

Where: ρ𝓁i - elongation of the continuous segment of fibers, mm; 𝓁i - length of the continuous segment of fibers, mm

normal stress ao in the material fiber (2) which is weakened by cross-perforations:

Where: ρ𝓁 o - elongation of the segment of fibers weakened by cross-perforation, mm; 𝓁o - length of the segment of fibers weakened by cross-perforation, mm.

Conclusion

By analysis of the experimental work in the axial strain of fiber material which is or not weakened by cross-perforations can be concluded that the stress-strain dependence is linear both in the cases, not only in the small deformation region, but also in the medium deformation region (up to 50%). Dispersion of quantitative values of stress-strain dependence for non crossperforated fibers is within ± 5.3%. For weakened cross-perforated fibers loaded with the same stress as non cross-perforated fiber, tension values are 6-11% lower (depending on the number of cross-perforations, dispersion ± 9.1%.) along the whole length of the fiber. The increase of dispersion of quantitative values of stress-strain dependence for cross-perforated fibers can be explained with the influence of stress concentration factor in the fiber's material in the region around perforations and dispersion of cross-perforations and fibers diameters. In summary, we have obtained innovative biomimetic textile material, which conventionally repeats the structure of the juniper fibers, namely, polypropylene fibers with cross-perforations (5-8μm, distance 150-200μm), impregnated with 5% juniper solution. Developed biomimetic material can be standardized for future widespread use in production of biomaterials.

Acknowledgement

This research was funded in the frame of a Eureka/MNT ERA- Net European consortium, Project "Fundamental and Industrial Fossilized Resin Research for the Production of Composite Material" Nr. E! 5798.

References

- Hanninen T, Kontturi E, Leppanen K, Serimaa R, Vuorinen T (2011) Kraft pulping of Juniperus communis results in paper with unusually high elasticity. Bio Resources 6(4): 3824-3835.

- Gross KA, Ezerietis EJ (2003) Juniper wood as a possible implant material. J Biomed Mater Res A 64(4): 672-683.

- Hanninen T (2011) Studies on the ultra structure of natural fibres and its effects on the fibre utilization", School of Chemical Technology Department of Forest Products Technology, Aalto University, Finland 116: 24-28.

- 4 Efremov EA, Zikova ID, Efremov AA, Strukova EG (2011) Component composition of the essential oil of the paw and Siberian Evenkia cones- berries of the juniper. Chemistry of vegetable raw materials 2: 127131.

- Lantto TA, Colucci M, Zavadova V, Hiltunen R, Raasmaja A (2009) Cytotoxicity of curcumin, resveratrol and plant extracts from basil, juniper, laurel and parsley in SH-SY5Y and CV1-P cells. Food Chem 117(3): 405-411.

- Stanzl-Tschegg SE (2011) Wood as a bioinspiring material. Mat Sci Eng C 31(6): 1174-1183.

- Aho AJ, Rekola J, Matinlinna J, Gunn J, Tirri T, et al. (2007) Natural composite of wood as replacement material for ostechondral bone defects. J Biomed Mater Res A Appl Biomater 83(1): 64-71.

- Voskerician G, Jin J, White MF, Williams CP, Rosen MJ (2010) Effect of biomaterial design criteria on the performance of surgical meshes for abdominal hernia repair: a pre-clinical evaluation in a chronic rat model. J Mater Sci Mater Med 21(6): 1989-1995.

- Laschke MW, Haufel JM, Scheuer C, Megner MD (2009) Angiogenic and inflammatory host response to surgical meshes of different mesh architecture and polymer composition. J Biomed Mater Res B Appl Biomater 91(2): 497-507.

- Horan RL, Bramono DS, Stanley JR, Simmons Q, Chen J, et al. (2009) Biological and biomechanical assessment of a long-term bioresorbable silk-derived surgical mesh in an abdominal body wall defect model. Hernia 13(2): 189-199.

- Huber A, McCabe GP, Boruch AV, Medberry C, Honerlaw M, et al. (2012) Polypropylene-containing synthetic mesh devices in soft tissue repair: a meta-analysis. J Biomed Mater Res B Appl Biomater 100(1): 145-154.

- Czichos H, Saito T, Smith L (2006) Springer handbook of materials measurement methods. Springer, Germany, pp. 1208.