Diffusion Infiltration of Miscible Cement Suspensions in Sandy Soils

Dimitrios Christodoulou*

Department of Environmental Sciences, University of Thessaly, Larissa, Greece

Submission: February 21, 2023; Published: March 01, 2023

*Corresponding author: Christodoulou Dimitrios, Assistant Professor, Department of Environmental Sciences, University of Thessaly, Campus Gaiopolis, Larissa, Greece

How to cite this article: Dimitrios Christodoulou. Diffusion Infiltration of Miscible Cement Suspensions in Sandy Soils. Ann Rev Resear. 2023; 8(4): 555748. DOI: 10.19080/ARR.2023.08.555748

Abstract

The safe construction and operation of many engineering projects often requires the improvement of the properties and mechanical behavior of the soil formations occurring in their area. Impregnation injections are one of the oldest methods of improving soil formations and present a wide range of applications. A phenomenon, which is often observed during the process of performing impregnations, is related to the filtering that the suspension undergoes from the soil formation as it flows through it. It consists in the retention of the cement grains, which form the basis for the preparation of the suspension, from the soil, which is soaked. In the context of the present study, the existence of the phenomenon of the retention of solids by the sandy formations was investigated, utilizing the volume of suspension collected at the outlet of the impregnation column and the possible differentiation of the ratio of water to cement collected in the volumetric containers in relation to the initial water to cement ratio of the slurry injected.

Keywords: Permeation Grouting; Suspensions; Injectability; Filtration

Introduction

The safe construction and operation of many engineering projects often requires the improvement of the properties and mechanical behavior of the soil formations occurring in their area. Impregnation injections are one of the oldest methods of improving soil formations and present a wide range of applications. The object of this work is the quantification of the injectability and penetrability of cement suspensions in sandy soils and the investigation of the parameters and mechanisms that enter and influence it. The term “Injectability” describes the ability of a specific suspension to impregnate a specific soil under a specified impregnation pressure. The term “Penetrability” describes the maximum length from the injection point that a specific suspension can penetrate into a specific sandy soil under a specified maximum infiltration pressure [1]. From their definition, these parameters appear to be decisive for the assessment of the feasibility of impregnation injections, the choice of the appropriate suspension and, therefore, the economics of the injection program. Many research efforts have been made in order to study the permeability of suspensions of common and fine-grained cements and the eventual retention of cement by sandy formations [2-8].

Materials and Procedures

The objective of a cement slurry injection program is to create a composite material consisting of the soil and the cement slurry that has been injected into its pores. In the present research, impregnation injections were performed with cement suspensions of various types and particle sizes in selected sand particle sizes. For the needs of this laboratory investigation, three types of cement were used, namely a pure Portland cement, a composite Portland cement and a pozzolanic cement denoted as CEM I, CEM II/B-M and CEM IV/B, respectively, according to EN 197-1. The selection of the specific types was based on the fact that they represent common industrial products available on the market during the current time period. In the present work these cements are referred to as I/42.5, II/32.5 and IV/32.5, respectively, because that is how they are designated by their producer. The composition and chemical analysis of these cements were determined in the laboratories of TITAN S.A. cement. Cement I/42.5 contains clinker at 90% of its composition, while in cements II/32.5 and IV/32.5 the percentage of clinker is reduced to 63% and 58%, respectively. The sum of pozzolan and fly ash in II/32.5 and IV/32.5 cements is 23.5% and 38%, respectively.

The nominal maximum grain size, dmax, of these cements is 100 μm while the d98 size ranges between 56 μm and 68 μm. To produce the fine-grained cements, which were the focus of this investigation, the cements were milled to obtain three additional grain sizes from each cement type.

Grinding was done with a special laboratory mill. The AJ-100 laboratory mill, unlike conventional ball mills, does not contain grinding media and relies on grinding using impinging air currents. In addition, it has a high-speed separator to determine the maximum grain of the material resulting from grinding. Clean dry air is required for grinding purposes, which refers to the production of fine-grained cements by the dry method. The cements obtained after the first, second and third grinding stages had a maximum nominal grain size, dmax, approximately equal to 40 μm, 20 μm and 10 μm. It is emphasized that the grinding process did not change the composition and chemical composition of the cements at all. The type I/42.5 cement proved extremely difficult to grind, for the capabilities of the mill, resulting in small quantities of cement being produced in a reasonable time, while the grinding of the type IV/32.5 cement showed little difficulty in adjusting the mill to control the of produced particle size composition. The parent sand used for the production of the individual sand fractions comes from the company TITAN SA. and is used by the company’s Concrete Technology Laboratory for strength testing. It is a quarry sand with angular grains, the mineralogy of which can be characterized as calcareous. With appropriate processing in the laboratory (sieving and washing) six fractions were separated.

Cement Retention from Sands

A phenomenon, which is often observed during the process of performing impregnations, is related to the filtering that the suspension undergoes from the soil formation as it flows through it. It consists in the retention of the cement grains, which form the basis for the preparation of the suspension, from the soil, which is soaked. In the context of the present study, the existence of the phenomenon of the retention of solids by the sandy formations was investigated, utilizing the volume of suspension collected at the outlet of the impregnation column and the possible differentiation of the ratio of water to cement collected in the volumetric containers in relation to the initial water to cement ratio of the slurry injected. The procedure followed to use the volume of slurry collected after exiting the impregnation column for the short and long columns was as follows. During the impregnation - if this was possible - the outflow quantity of the suspension was collected at the outlet of the column using five containers of equal volume. This quantity was used to check if the suspension had undergone filtration during its passage through the sand mass. Specifically, the amount of suspension included in each container was weighed and then placed in a drying oven at a temperature of 105°C for 24 hours. After this time, each container was weighed again. Using the weights it was possible to determine with sufficient accuracy the amounts of cement and water contained in the suspension of each container and to check whether the composition of the suspension varied as the injection progressed. Although with the weighing process it was not possible to accurately calculate the quantities of the components of the suspension (due to the possible binding of water by the cement), nevertheless the results were considered highly realistic and therefore reliable. The binding of water by the cement during the drying stage is unavoidable, but it does not introduce a significant error in the calculation of the amounts of cement and water [9]. In cases where impregnation was not possible, the PVC column was removed from the metal base, brought to a horizontal position and, after removing the amount of sand that had not been impregnated, the penetration length marked by the suspension was measured.

For the long columns, the result obtained from this procedure consists in quantifying the water-to-cement ratio of the slurry after it exits the impregnation column for each of the volumetric vessels used. A value of the water-to-cement ratio of the slurry was therefore obtained for each volumetric container, which was compared to the initial water-to-cement ratio of the injected slurry and, at the same time, the change in the ratio over time from the time the slurry exited the impregnation column. In short-length columns, the slurry exiting the impregnation column was collected in a volumetric tube and the final output was the total water-to-cement ratio determination, which was compared to the initial water-to-cement ratio of the slurry injected into the column. An increase in the water-to-cement ratio of the resulting slurry after leaving the impregnation column relative to the initial ratio and the collection of a slurry volume smaller than the predetermined one (volume of injected slurry twice the void volume of the sand column) were indications of retention of solids from the soil mass of the sand column. The majority of injections in long columns were carried out in uniform fractions of sands with cement suspensions combining 3 different fineness’s (F0, F2 and F3). Phenomena of cement retention from sands were observed in a few relative cases, which concern impregnations carried out with suspensions of common cements. The majority of injections in long columns were made in uniform fractions of sand with cement suspensions combining 3 different fineness’s (F0, F2 and F3). Phenomena of cement retention by sands were observed in a few relevant cases, concerning impregnations made with suspensions of common cements.

The water-to-cement ratios of the slurry determined after leaving the impregnation column show relatively small deviations from the initial water-to-cement ratio of the injected slurry, which is true for the majority of impregnations. For an initial water-to-cement ratio equal to 1:1, the range of variation of the W/C ratio of the suspension after leaving the impregnation column was from 0.9:1 to 1.2:1. Similarly, for initial water-tocement ratios equal to 2:1 and 3:1, the water-to-cement ratios of the exit suspension ranged from 1.78:1 to 2.2:1 and 2.75 to 3.3:1, respectively. (Table 1) lists data concerning the cases of cement retention of the suspension from the soil columns of uniform sands, which are an exception compared to the general trend that emerged from the experimental procedures. Specifically, these are suspensions I-F0-1-X and IV-F0-1-X, which were injected into soil columns of sand 10-14, as well as suspensions II-F0- 1-X and II- F0-2-X, which were injected into sand columns 14-25. At the exit of these suspensions from the impregnation columns, their obvious dilution was diagnosed. As can be seen from Table 1, for the injection performed with the II-F0-1-X slurry, water to-cement ratios equal to: 1.9:1, 2.7:1 and 4.1:1 were obtained for each of the volumetric collection vessels suspension. For the injection performed with the II-F0-2-X slurry, the water-tocement ratios ranged from 4.2:1 to 8.5:1 for each of the slurry collection containers. It should be noted that it was not possible to press a suspension volume twice the void volume of the soil column due to ceasing the flow of slurry from the column outlet after a certain period of time.

A similar behavior was observed for the I-F0-1-X suspension injected into a 10-14 sand column. Significant dilution of the slurry exiting the column was noted with water to cement ratios ranging from 2.8:1 to 4.8:1. Also in this case, the volume of suspension injected was less than twice the void volume of the soil column. For injection performed with IV-F0-1-X suspension in a 10-14 sand column, the final ratio ranged from 1.7:1 to 3:1. From the data in Table 1 it follows that filtering effects of the suspension within the soil column were found only for suspensions of common cements. In contrast, in the injections carried out with suspensions of fine-grained cements in columns of uniform sands, no filtering effects were observed, in general. Successful injections were found to match the water-to-cement ratio of the slurry collected at the outlet of the impregnation column and the initial water-to-cement ratio introduced. Negligible to zero deviations were observed, a fact which does not strengthen the case of retention of the solid grains of the suspension by the mass of the soil column. Reinforcingly, consistency was also found regarding the temporal evolution of the water-to-cement ratio of the suspension collected in volumetric containers, as negligible variations were observed from container to container. The difference in the behavior of common and fine-grained cements is probably attributed to the geometric correlations of the suspension and soil grain sizes. The grains of common cement are filtered by the uniform soil formation, so that only those suspended solids that meet the geometric conditions continue to flow. In contrast, the occurrence of filtration in injections with suspensions of finegrained cements is minimal to non-existent, since the grain size in these cements varies between very limited limits, so that the finer percentage of them continues its flow for a longer time.

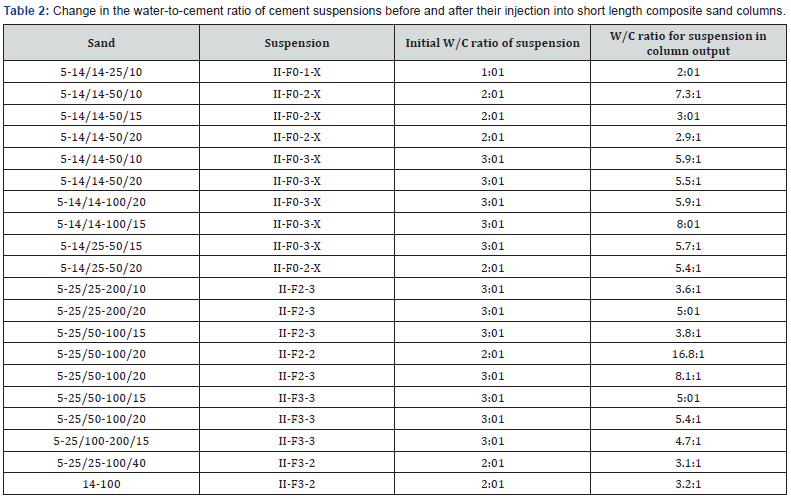

The investigation of solid grain retention of cement suspensions by soil sand columns was further extended to the composite sands by performing injections in short length columns.

As mentioned above, the suspension, after leaving the impregnation column, was collected in a volumetric tube and the water-to-cement ratio of the suspension that had passed through the sand mass was determined. In the majority of impregnations, as in the uniform sands, no phenomena of retention of the solid grains of the cement by the soil formations were observed. The results listed in Table 2 refer to the cases in which cement retention of the examined suspensions from the soil columns of the composite sands was found. These exceptions concern a total of 20 short column impregnation tests. In Table 2 a comparison is made between the initial injected water-to-cement ratio and the final water-to-cement ratio of the slurry collected at the exit of the column. These exceptions are for a total of 20 short column impregnation tests. Table 2 compares the initial water-to-cement ratio injected and the final water-to-cement ratio of the slurry collected at the column exit. The geometric relationships that exist between the cement suspension grains and the soil formation appear to be the cause of retention of the suspension solid grains by the sand fractions. The well-graded common cements combined with the graded composite sands favor the occurrence of filtration since they include a wide variety of grain sizes. Graded soils appear to filter suspensions and fine-grained cements, in some cases, allowing flow of only those suspended solids whose size favors infiltration. The grain size range of fine cements is relatively limited compared to that of common cements, however in the case of graded composite sands it appears that the geometrical constraints imposed by soil formation are capable of contributing to the occurrence of suspension filtration. The general conclusion that emerges is that the good gradation of one or both of the injection factors (cement and sand) can contribute in some cases to the retention process of the suspension grains by the sand grains of the soil column.

Discussion and Conclusions

a) Filtering effects of the suspension within the soil column were found only for suspensions of common cements.

b) In the injections carried out with suspensions of finegrained cements in columns of uniform sands, no filtering effects were observed, in general.

c) Successful injections were found to match the water-tocement ratio of the suspension collected at the outlet of the impregnation column and the initial water-to-cement ratio injected. Negligible to zero deviations were observed, a fact which does not strengthen the case of retention of the solid grains of the suspension by the mass of the soil column.

d) The difference in the behavior of common and finegrained cements is probably attributed to the geometric correlations of the suspension and soil grain sizes.

e) The grains of common cement are filtered by the uniform soil formation, so that only those suspended solids that meet the geometric conditions continue to flow. In contrast, the occurrence of filtration in injections with suspensions of fine-grained cements is minimal to non-existent, since the grain size in these cements varies between very limited limits, so that the finer percentage of them continues its flow for a longer time.

f) The geometric relationships that exist between the cement suspension grains and the soil formation appear to be the cause of retention of the suspension solid grains by the sand fractions.

g) The well-graded common cements combined with the graded composite sands favor the occurrence of filtration since they include a wide variety of grain sizes. Graded soils appear to filter suspensions and fine-grained cements, in some cases, allowing flow of only those suspended solids whose size favors infiltration.

h) The general conclusion that emerges is that the good gradation of one or both of the injection factors (cement and sand) can contribute in some cases to the retention process of the suspension grains by the sand grains of the soil column.

References

- Shibi M, Senthil VA, Saravanan S, Uma MK (2020) The emergence of COVID-19 as a global pandemic: Understanding the epidemiology, immune response and potential therapeutic targets of SARS-CoV-2. Biochimie 179: 85-100.

- Iain Robertson‐Steel (2006) Evolution of triage systems. Emerg Med J 23(2): 154-155.

- Simon de L, Jamie Lopez B, Maria Z, Oluwafunmi A, Gayatri A, et al. (2020) Emergence of a Novel Coronavirus (COVID-19): Protocol for Extending Surveillance Used by the Royal College of General Practitioners Research and Surveillance Centre and Public Health England. JMIR Public Health Surveill 6(2): e18606.

- (2020) Role of primary care in the COVID-19 response Interim guidance.

- Williams S, Tsiligianni I (2020) COVID-19 poses novel challenges for global primary care. npj Prim Care Respir Med p. 30.

- Kirsty Challen, Steve WG, Richard W, Andrew B, Mike C, Christopher F, et al. (2012) Evaluation of triage methods used to select patients with suspected pandemic influenza for hospital. Emerge Med J 29(5).

- Paul Sebo, Benoit Tudrej, Julie Lourdaux, Clara Cuzin, Martin Floquet, et al. (2021) Cross sectional study of the clinical characteristics of French primary care patients with COVID- 19. Scientific Reports 11: 12492.

- Romero-Gameros CA, Colin-Martínez T, Waizel-Haiat S, Vargas-Ortega G, Ferat-Osorio E, et al. (2021) Diagnostic accuracy of symptoms as a diagnostic tool for SARS-CoV 2 infection: A cross-sectional study in a cohort of 2,173 patients. BMC Infect Dis 21(255).

- (2020) Management of a Suspected Case - COVID -19.

- (2020) Coronavirus disease 2019 (COVID-19) in the EU/EEA and the UK - ninth update. National Guidelines for Clinical Management and Treatment of COVID19-19. Eur Centre Dis Prevent Control.

- (2020) World Health Organization. Public health surveillance for COVID-19: interim guidance COVID-19: Surveillance, case investigation and epidemiological protocols.