Laboratory Errors in the Fabrication of Complete Dentures. A Clinical Survey

Fotoula Nikolopoulou1* and Anestis Chrysostomidis2

1Assistant Professor of the Dental School, National and Kapodistrian University of Athens, Greece

2Medicine School, National and Kapodistrian University of Athens, Greece

Submission: November 07, 2019 Published: November 18, 2019

*Corresponding author: Fotoula Nikolopoulou, Assistant Professor of the Dental School, National and Kapodistrian University of Athens, Greece

How to cite this article: Fotoula Nikolopoulou, Anestis Chrysostomidis. Laboratory Errors in the Fabrication of Complete Dentures. A Clinical Survey. Adv Dent & Oral Health. 2019; 11(4): 555820. DOI:10.19080/ADOH.2019.11.555820

Abstract

Introduction: The purpose of this study was to evaluate and discuss laboratory errors which were collected in Prosthodontics Department of the Dental School of the National and Kapodistrian University of Athens. The collected data are analyzed, and we have created a report of the findings.

The goals of this study were:

a) To identify the most common mistakes during laboratory procedures when performing prosthodontic treatment.

b) To note the incidence and trends of mistakes during student clinical education.

Material and Methods: The collected data from the October of 2016 until the June of 2019 were evaluated and recorded for type of errors made in submission of laboratory work by students.

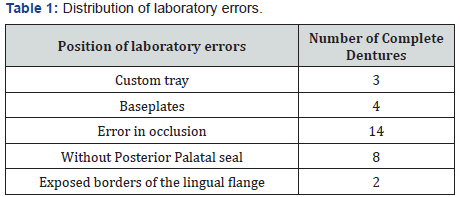

Results: The five most common laboratory errors observed by students and instructors. These errors were in custom trays, baseplates, error in occlusion, without posterior palatal seal and the exposed borders of the lingual flange. There were laboratory errors in thirty –one complete denture [32,97%].

Clinical Relevance: Dentists must assume responsibility for laboratory procedures and must provide adequate and necessary information for a successful fabrication of complete dentures.

Keywords: Laboratory Errors; Complete Dentures; Custom Tray; Errors in Occlusion; Baseplates

Introduction

It is imperative that a dentist assume the responsibility and initiative in designing and planning complete dentures for their patients. The laboratory technicians are responsible for handling the materials and mechanical details. Dentists are negligent if the laboratory technicians are entrusted with the responsibility for the biologic and physiologic needs of patients. The results of many errors made during the fabrication of a complete denture may not be recognizable when they occur. This article, therefore, has two aims:

a) To call attention to results that can be attributed to these errors.

b) To identify steps that can be taken to avoid these errors. The errors are listed in the order that they would occur during the fabrication of a complete denture.

Dental Stone Casts

i. If a technician doesn’t use the correct water/powder ratio and put excess water, the cast will have voids. It will have reduced strength. Evaporation of excess water continues for about 24 hours following pouring. As water evaporates the cast shrinks and increases in density [1,2]. If a denture is constructed on this cast, this prosthesis will not have good retention and stability.

ii. Different manipulative conditions control the setting expansion of gypsum cast. Increases in spatulation will increase the setting expansion [3,4]. Ease of manipulation and production of the cast in a reasonable time is desirable for an accurate cast [5].

iii. A thick mix of stone is difficult to pour because it doesn’t flow well. It may trap air. The setting expansion of the stone is also affected, resulting in a cast that is not dimensionally accurate [6]. A technician must always use the exact amount of powder and water recommended by the manufacturer to make a smooth and creamy mix [7].

iv. If a technician adds a stone mix to the impression too rapidly, air may be trapped between the stone and the impression, resulting in air voids in the cast [3].

v. If the cast is separated from the impression too soon, it may cause problems on the strength of the cast. The dry strength of the cast is more than two times that of the wet strength, so a wait of at least 24 hours is advisable if the ridge is high and thin [8].

vi. If a dentist has not placed the posterior palatal seal, either in the impression or by cast carving, a technician cannot correctly determine the location outline, and depth of the posterior palatal seal from the hard-stone cast. The outline of cast carving technique should be done by a dentist when a patient is present [9].

Custom Trays

i. The handles of the trays should permit free upward and downward of the upper and lower lip. If they aren’t positioned correctly, the placement of the tray on the residual ridge will not be in correct position, while the final impression materials set [8].

ii. If a dentist allows the technician to design and fabricate a custom tray, there will be problems in the retention of complete dentures. A custom tray should be chosen by a dentist, who will based on anatomy, physiology and the impression technique [8,10].

iii. If there is a faulty construction of the custom tray the correct thickness of impression material will not be permitted. For example, zinc oxide pastes impressions require closer fitting tray than alginate [10].

Occlusal Rims

i. If the presence of undercut areas on the ridges of the cast are not blocked out, the baseplates with occlusal rims will break the cast as withdrawal is attempted, such undercut areas will therefore need to be blocked out before the base material is adapted to the cast [11].

ii. If the baseplates are not adapted so accurately to the cast, any discrepancy in the adaptation of them will make it impossible for the dentist to record the correct anatomical relationship of the patient’s jaw [12].

iii. If the occlusal rims are bulky, they will inhibit patients from closing the mouth in a normal manner. A dentist will record errors in the jaw relations [5,13]. The bulk of the rim in the anterior region of both upper and lower rims should be reduced as much as possible to avoid constricting the tongue [14].

Mounting Casts in an Articulator

i. If a face-bow is not used to mount a maxillary cast in an articulator, the casts are mounted too far anterior or posterior in an articulator. This inaccuracy will be more apparent in the mouth [15].

ii. If the casts are not mounted in an articulator in the dental office inaccurate jaw relation records may be made, because a laboratory technician cannot know how the casts relate to each other [6].

iii. Improper powder-to-water ratio is used, it can cause excessive expansion of mounting stone. The result can be an increase of vertical distance between the maxillary and mandibular casts [16].

iv. If the casts are not wetted before they are mounted in an articulator, the dry casts will absorb water from mounting stone. This can result a dry layer of stone between the casts and rest of the mounting stone will be formed. This soft layer may make the mounting casts in an inaccurate position [6].

v. If a dentist allows the technician to develop an occlusal scheme that will not meet the needs of this patient [17].

vi. If maxillary incisors are placed palatal, they will restrict the space for the tongue, and possible consequence is denture displacement, speech interferences and lack of the support the lip [18,19].

In mandibular dentures, the common fault is associated with placement of the molars too lingual with restriction of tongue space [20].

vii. If a balanced occlusion is set without anteroposterior and mediolateral curves, dentures, patients will have problems during functional movements [21].

Contouring and Finishing the Wax Surfaces

i. If a large buccal concavity is built into the dentures it means that the teeth must be lingually displaced, and as the muscle is unable of functioning without adequate support, patients will complain of food falling into the check [13,22].

ii. If the rugae area is not waxed properly, the denture base creates phonetic disturbances with the sound “s” or “t” [23].

iii. The highly skilled dental technician will carve the wax on a trial denture to the contour desired to the finished denture, thus avoiding unnecessary dimensional change caused by excessive reduction of bulk during finishing and polishing [23,24].

Flasking the Complete Denture

i. If a dry cast in invested, the stone will be susceptible to crushing when the resin is packed during processing. There will be noticed an increased vertical dimension of occlusion [6].

ii. If there are undercuts in the investing stone after complete dentures are flasked, these undercuts will make separation of the flask halves difficult [5].

iii. If the investing plaster is compressed or crushed, it will cause an increase in the vertical dimension of occlusion, which will be evident when the complete dentures are placed in the mouth. This error can be corrected by selective grinding, when complete dentures have been remounted in an articulator [25].

iv. If the flasks are placed in boiling water longer than 5 minutes, the wax will become totally fluid and penetrate the stone investment. Wax absorbed by the investing stone prevents the resin to adhere to the stone [26]. If the temperature of water is lower than 100 °C and then it increases gradually the wax doesn’t melt well, so that the risk arises of allowing the wax to be absorbed into the stone. Acrylic resin will be discolored by no melted wax [22,27].

v. When the water has been drained from the flasks the mold is washed again with the boiling water containing a detergent. If solvents such as chloroform are used, they affect on acrylic resin [28].

vi. If a technician carelessly applies irreversible hydrocolloid separating medium, it will remain and dry around the denture teeth. As the patients wear complete dentures this material will dissolve gradually, and the space will be filled with food and bacterial [29].

Preparing, Packing and Processing of Acrylic Resin

i. It is known that the powder / liquid ratio is 3:1 by the volume. If it is too high, not all the polymer will be wetted by monomer and the cured acrylic resin will be granular [30].

ii. If there is too much monomer, there will be greater shrinkage. In correctly proportioned acrylic dough, the shrinkage is about 7% [31].

iii. If a technician places the resin during the rubbery stage, there will be too much resistance to compression. Tooth movement, alteration of the vertical dimension and centric relation will be caused [32].

iv. The slightest discrepancy in the closure of the two halves of the flask will cause an error in the occlusion [11].

v. It is known that the boiling point of the monomer is 212 °F. If this heat is not controlled, the exothermic reaction will cause the monomer in the thick bulky sections of the denture to boil during the curing process and result in areas of porosity [33].

vi. If the flasks are forced to cool quickly rather be cool gradually by contract with cold water, it may induce stress that will strain and warp the complete dentures [34].

Deflasking and Polishing a Complete Denture

i. If the deflasking is not done with care, a technician won’t avoid flexing and breaking of complete dentures [26].

ii. It is important to remove a denture from the flask until it has completely cooled. As the denture cools, a dimensional change occurs. The change in the denture base is greater than that occurs in the plaster. Because gypsum restricts the acrylic from shrinking, stress is built up within the denture. This stress will be relieved. If it is relieved while the denture is in the flask, there will be little distortion in the base on removal. If dentures are removed from the flask too soon, the dimensional change will be greater and the fit poorer [27].

iii. The polished surfaces of a complete denture are essential for the retention of complete dentures by muscular forces. If a laboratory technician doesn’t develop and finish the external surfaces of complete dentures correctly the result will be an unstable denture [18].

iv. If polishing is done under no wet conditions, temperatures will be sufficient to decompose and distort the denture base [35].

v. One of the most common errors of a technician is to try to simulate gingival portion, such as it appears in periodontal diseases so that food will stick between the teeth [36].

vi. If a polished denture is not stored in water before being delivered to the patient’s dimensional changes of the denture base material will occur. Residual monomer may be released from the denture and irritate the oral tissues [27].

Materials and Methods

This clinical survey was carried out at the Department of Prosthodontics, of the Dental School, National and Kapodistrian University of Athens. We examined the laboratory errors during the fabrication of the complete dentures. Ninety-four complete dentures had been constructed in the Second Department of Prosthodontics. The students must construct complete dentures for dental education. The duration of this survey was four academic years. The laboratory errors which had been presented, were written down, the errors were listed in the order that they occurred during the fabrication of the complete denture.

a) The faulty construction of custom tray didn’t permit the correct thickness of the final impression [10,11].

b) We also recognized that the baseplates were not adapted so accurately to the cast and it is impossible for the student to record the correct anatomical relationship of the patient’s jaw.

c) Eight casts were not mounted in the articulator in accurate jaw relation.

d) Errors in occlusion were presented in ten complete dentures. The selection of the occlusal scheme was not correct. There were absences of the anteroposterior and mediolateral compensating curves. Teeth were placed on the residual ridge incline and they ascended to the pad.

During the delivery of the complete dentures, we recognized the following errors. First, there were not posterior palatal seal onto the six CD. This process was determined in the mouth and its location was transferred onto the final impression. The technicians didn’t curve into the cast the posterior palatal seal.

At the time of the initial placement of the mandibular dentures, there were exposed borders at the lingual flange. They related to unnecessary movement of the denture or soreness the alveolar lingual sulcus at a later date. Another problem was the sharp borders in the frenal notches.

Results

We observed that there were laboratory errors in thirty-one complete dentures [32,97%]. The Table 1 shows the laboratory errors, which had been done by technicians.

Discussion

Some errors in denture fabrication can result from faulty dental laboratory procedures. A technician should be supplied with detailed legible instructions by a dentist. The well-trained or thoroughly experienced dental laboratory technician recognizes the importance of using only base materials, investments, casting alloys, and so forth that have been certified by ADA. Ninetyfour complete dentures had been constructed in the second Department of Prosthodontics of the Dental School of Athens. The clinical procedures for construction of CD were made by students for educational experience. The laboratory procedures were constructed by technicians in their private technical companies. We observed that there were laboratory errors in thirty-one CD [32,97%] Five main laboratory errors were reported:

i. Faulty custom tray in 3 complete dentures.

ii. In 4 complete dentures there were faulty baseplates. Two were not fit accurately and the under cuts of two casts were not blocked out.

iii. There were 14 errors in occlusion rims.

During the delivery of the CD we recognized that there was not palatal seal onto the 8 dentures. The technicians didn’t curve into the cast the shape of the posterior palatal seal. Only two mandibular dentures were exposed the borders in the lingual flange. A small number of articles have been written concerning the laboratory errors. Chan et al. [37] evaluated the laboratory errors among dental students and observed five common laboratory errors.

a) Improperly articulated casts.

b) Teeth weren’t properly set.

c) Light contacts in maximum intercuspation.

d) Baseplates inadequately sealed.

e) The lack of posterior palatal seal carved into the master cast [37].

In a clinical survey by Juszcqyk et al. it was found that out of 803 dental laboratories only 9% scored communication as very good, and only 26% dental students communicated with dental laboratories effectively [38]. Other authors in their study concluded that there were three main reasons were for laboratory errors:

i. Lack of recognition the errors by the dental team.

ii. Lack of effective communication in laboratory script.

iii. A lack of knowledge by the dentist of technical procedures [38].

Conclusion

This article was not written to place blame on anyone for errors that may occur during the fabrication of a complete denture. Dentists and technicians both participate in the production process and must share in the success or failure of the complete denture. Dentists must provide an easy-to-follow work authorization to the laboratory in written instructions. Both dentists and technicians must recognize their respective responsibilities in providing prosthodontic service.

References

- Ellinger CW, Rayson JH, Terry JM, Rahn AD (1975) Synopsis of complete dentures. 1st edn, Lea and Febicer, Philadelphia pp. 220-229.

- Graig RG, Powers JM, Wataha JC (2000) Dental Materials properties and manipulation. 7th edn, Mosby, St Loui, USA pp. 211-217.

- Earnshaw R (1973) The consistency of dental gypsum products. Aust Dent J 18(1): 33-37.

- Garber DK, Powers JM, Brandau HE (1985) Effect of spatulation on the properties of high-strength dental stones. J Mich Dent Assoc 67(3): 133-136.

- Harrison A, Huggett R, Murphy WM (1990) Complete dentures construction in general dental practice: An update of the 1970 survey, Br Dent J 169(6): 159-163.

- Fan PL, Powers JM, Reid BC (1981) Surface mechanical properties of stone, resin, and metal dies. J Am Dent Assoc 103(3): 408-411.

- Rudd KD, Morrow RM, Bange AA (1969) Accurate casts. J Prosthet Dent 21(5): 545-554.

- Morris JC (1997) Handles on custom trays for complete master impressions. J Prosthet Dent 78(3): 331.

- Ettinger RΙ, Scandrett FR (1980) The Posterior palatal seal. A review. Aust Dent J 25(4): 197-200.

- Knap FJ (1979) Border molding in mandibular denture impressions. J Prosthet Dent 42(3): 351-352.

- Zarb G, Bolender C, Hickey J, Carlsson G (1990) Boucher’s Prosthodontic Treatment for Edentulous Patients. 10th edn, CV Mosby Co, Saint Louis pp. 303-305

- Basker RM, Davenport JC, Tomlin HR (1983) Prosthetic treatment of the edentulous patient. 2nd edn, MacMillan Press, London, UK pp. 176-188.

- Osborne J, Wilson HJ (1970) Dental Mechanics for Students. 6th edn, Staples Press, London, UK p. 51-53.

- Blakeslee RW, Renner RP, Shiu A (1980) Dental technology. Theory and practice, The CV Mosby Company, St Louis pp. 95: 98-100.

- Meyer FS (1951) Dentures causes of failures and remedies. J Prosthetic Dent 1(6): 672-691.

- Philips RW (1984) Elements of dental materials. 4th edn, WB Sounders Co, Philadelphia p. 76-84.

- Sheppard IM, Sheppard SM (1971) Denture occlusion. J Prosthet Dent 26(5): 468-476.

- Rahn A, Heartwell C (1993) Textbook of complete Dentures. 5th edn, Lea and Febiger, Philadelphia pp. 329-331.

- Renner R (1981) Practical Complete Denture Occlusion. In Renner Red Complete dentures, Masson Publishing Inc, New York, USA pp. 122-140.

- Levin B (1977) A review of artificial tooth forms including a preliminary report on a new a posterior tooth. J Prosthet Dent 38(1): 3-15.

- Grant AA, Johnson W (1983) An introduction to Removable Denture Prosthetics, Churchill Livingstone, Edinburg p. 43-45.

- Renner RP, Blakeslee RW (1978) Basic wax contouring for complete dentures. J Prosthet Dent 40(3): 343-348.

- Rosenthal RL, Kemper JT (1974) The ‘blow-wax’ technique for stippling dentures. J Prosthet Dent 32(3): 344-347.

- Jeganathan S, Payne JA (1993) Common faults in complete dentures: A review. Quintessence Int 24(7): 483-487.

- Sharry JJ (1972) Denture failures related to occlusion. Dent Clin North Am 16(1): 119-126.

- Renner R. Complete dentures (1989) A Guide for patient treatment, Masson Publishing Inc, New York, USA pp. 200-2013.

- Rοraff AR, Stansbury BF (1972) Errors caused by dimensional change in mounting material. J Prosthet Dent 28(3): 247-252.

- Winkler S (1979) Essentials of Complete Denture Prosthodontics, WB Saunders Co, Philadelphia, USA pp. 350-359.

- Rudd RW, Rudd KD (2001) A review of 243 errors possible during the fabrication of a removable partial denture: Part III. J Prosthet Dent 86(3): 277-288.

- Stafford GD, Huggett R (1978) Creep and hardness testing of some denture base polymers. J Prosthet Dent 39(6): 682-687.

- Takamata T, Setcos JC (1989) Resin dentures bases: review of accuracy and methods of polymerization. Int J Prosthodont 2(6): 555-562.

- McCabe JF, Wilson HJ (1974) Polymers in Dentistry. J Oral Rehabil 1(4): 335-351.

- Firtell D, Harman L (1983) Porosity in boilable acrylic resin. J Prosthet Dent 49(1): 133-134.

- Wong DM, Cheng LY, Chow TW (1999) Effect of processing method on the dimensional accuracy and water sorption of acrylic resin dentures. J Prosthet Dent 81(3): 300-304.

- Soni PM, Powers JM, Craig RG (1977) Physical and mechanical properties of acrylic and modified acrylic denture resins. J Mich Dent Assoc 59(7-8): 418-422.

- Sowter J, Barton R (1986) Removable Prosthodontic Techniques. Dental Laboratory Technology Manuals, Revised, University of N. Carolina Press p. 80-86.

- Chan CT, Sukotjo C, Gehrke KW, Yuan JC, Campbell SD, et al. (2013) Laboratory quality Assurance in the Department of Restorative Dentistry at the University of Illinois at Chicago, College of Dentistry. J Prosthodont 22(1) 85-91.

- Afsharzand Z, Rashedi B, Petropoulos VC (2006) Communication between the dental laboratory technician and dentist: Work authorization for fixed partial dentures. J Prosthod 15(2): 123-128.