Micro and Nano Plastics Movement in Body

Dimitrios Christodoulou1*, Philotheos Lokkas2, Ioannis Markou3, Alexandros Droudakis4, Xenofon Spiliotis1, Dorothea Kasiteropoulou1 and Nikolaos Alamanis5

1Department of Environmental Sciences, University of Thessaly, Greece

2Emeritus Professor, University of Thessaly, Greece

3Department of Civil Engineering, Democritus University of Thrace, Greece

4PhD Civil Engineer, Geosynthetic Engineering Specialist, Greece

5Department of Agriculture, University of Thessaly, Greece

Submission: November 18, 2021; Published: November 24, 2021

*Corresponding author: Dimitrios Christodoulou, Department of Environmental Sciences, University of Thessaly, Greece

How to cite this article: Dimitrios C, Philotheos L, Ioannis M, Alexandros D, Xenofon S, et al. The Development of Practice in Permeation Grouting by using Fine-Grained Cement Suspensions-A Review. Organic & Medicinal Chem IJ. 2021; 11(3): 555811. DOI: 10.19080/OMCIJ.2021.11.555811

Abstract

Micro and Nano plastic body movement studies are in the early stages of research without many data. However, studies on rats, clams, and fish have shown that the smaller the particle, the more likely it is to be absorbed and remain in the body. When small plastic particles are introduced into cells, they dissolve in macrophages, which can secondarily reach other organs of the human body, such as the liver, kidney, heart, and brain, so more research is necessary.

Keywords:Micro & nano plastic; Body movement; Cell accumulation; Cell absorption

Abbreviations:PET: Positron Emission Tomography

Introduction

The design related on the shear behavior of a soil material is of particular interest because it has a direct impact on practical problems of bearing capacity [1,2], stability of slopes and embankments [3,4,5] as well as permanent seismic movements of slopes [6,7,8]. The safe construction and operation of many technical projects often requires the improvement of the properties and mechanical behavior of the soil formations that appear in their area. Various methods are used to improve the soils, such as: the lowering of the well horizon, the vibrational condensation, the dynamic condensation, the preloading and the injections. The category of injections includes:

a. permeation grouting,

b. compensation grouting,

c. condensation injections and

d. high pressure vein injections.

Permeation groutings are one of the oldest methods for improving soil formations and have a wide range of applications [9]. According to Sudheer Kumar et. al. (2020), cement-grouting technique is more efficient than compaction method [10].

In general, permeation grouting aim at increasing the shear strength, the density and the stiffness, along with a reduction of the compressibility and the soil permeability. The grouts used to perform permeation groutings, based on their composition, can be divided into:

i. Suspensions,

ii. Solutions,

iii. Emulsions and

iv. Foams.

In the category of suspensions belong these of clay and bentonite, the mixtures of bentonite-cement, pozzolanic-cement, Portland cement and fine-grained cements. Typical representatives of chemical solutions are sodium silicate, amino plastics, pheno plastics, acrylics and acrylamides. The most popular emulsions are asphalt, a combination of asphalt - soap - casein in water, and asphalt with a suitable filler such as clay in water, which have been applied to soil stabilization and waterproofing problems. Foams include cement or clay-cement suspensions that can undergo a physical or chemical modification that creates air bubbles within them.

Practically, and in terms of Engineering applications, the distinction has prevailed in the following types of grouts:

A. Cement grouts,

B. Fine cement grouts,

C. Fuel solutions and

D. Resins.

Cement suspensions are low cost and environmentally friendly, but have a limited scope, which reaches up to the coarse sands. On the contrary, chemical solutions can penetrate fine-grained sands or coarse-grained sludges, but they are more expensive and some of them is considered harmful to the environment and humans. With the aim of replacing these chemical solutions with suspensions that are harmless to the environment, but also equally effective in terms of their penetration into soil formations, efforts have been made to develop new suspension-type materials based on fine-grained cements. The MC-500 is the oldest fine-grained cement in the literature and appeared on the international market in the early 1980s. The volume of applications of fine-grained cements has been systematically increased over the last 20 years. Due to stricter environmental protection laws and lower costs against chemical solutions, fine-grained cements appear to be gradually replacing chemical solutions in the field of impregnation injections. Fine-grained cements have been used mainly to control groundwater flows and/or to improve soil strength, in applications including dams, tunnels, landfills, bridges and large construction projects.

Injections in General

Injection is defined as the transmission process of a fluid material under pressure, to the required depth from the soil surface. The injection material, which is either a suspension of solid granules in water or a solution of chemicals, displaces the water from the soil pores and coagulates or solidifies in a short time. Injections are generally intended either to increase the shear strength, density and stiffness of the soil or to reduce compressibility and permeability.

Injection categories

The categories of injections as defined by European standards EN12715: 2000 and EN12716: 2000 are as follows:

a) Permeation Grouting,

b) Compensation Grouting and

c) Jet Grouting.

The use of permeation grouting is a method of improving the properties and mechanical behavior of the soil. The method is generally expensive and its choice depends on the relative cost with respect to other alternative solutions. It is based on the replacement of water (or air) of soil voids or rock mass cracks by a grout, that is pressed under low pressure, so as not to disturb the soil formation. It is the oldest method of injection and is usually applied to relatively small areas of soil that are far from the soil surface. The method is used in technical projects, aiming at controlling underground flows, increasing the shear strength of soil formation, reducing deformation or subsidence and filling gaps [9].

Historical background on permeation grouting

The first application of injections mentioned in the international literature is credited to the French engineer Charles Berigny, who in 1802 used grouts of clay and calcium oxides to stabilize stone walls in the port of Dieppe, which had lost their strength due to corrosion between the stones. Through this method, named by him “procédé d’ injection”, the stabilization and reduction of the permeability of the local alluvial deposits was achieved. Portland cement was first injected in England in 1838 by Marc Isambard Brunel to build the first Thames tunnel, and in France by Collin (1839) to fill cracks in the body of the Grosbois Dam [11,12]. At the beginning of the 20th century, due to the introduction of high-pressure pumps and pressure gauges, the ability to control the permeation pressure and the flow of grout increased considerably, resulting in a significant improvement on the equipment for performing an injection program [12].

The development of railway networks in the first half of the last century led to the widespread use of cement injections, especially for the repair and strengthening on the foundations of railway bridges to cope with the increased loads of trains. With James Greathead as a pioneer, between 1900 and 1930, mechanical systems and pumps were developed, capable of pumping high-pressure cement injection material deep into the ground. Through this way, problems related to the large dams that began to be built at that time and particularly problems of controlling the underground flows and strengthening the supports of the dams were solved [13]. Along with the development of the injection’s technique with cement grouts, the first injection materials based on chemicals in solution form began to appear. The first application of injections using a chemical solution (concentrated sodium silicate) was attributed to Jeriorsky, who introduced a “two-stage” injection method and for this reason he was awarded a patent in 1886 [11,12].

In 1909, Lemaire and Dumont proposed a “one-step” chemical injection method with a dilute solution of silicon and acid, which, however, in application, presented significant practical problems. In 1925, the Dutchman Joosten perfected the “two-stage” method based on sodium-hydrated silicate and extended its scope to soils with fine sand granulometry. The system introduced by Joosten was widely used in the construction of the Berlin Underground in the 1930s. An important impetus to the application of injections was given in 1933 by the invention of the “tube-à-manchette” (TAM) by the Swiss engineer Ischy, which allows the permeation of grouts with different properties, in any order at any step of time in the same drilling [11,12]. In 1934 Mayer developed a “one-step” method by which he was able to control the curing time of the silicate suspension by helping to solve some of the practical problems of Joosten’s method.

Reports of cement grouts injections are also related to the construction of the Estacada Dam barrier wall in Oregon, USA (1910-1912). The construction of the Hoover Dam (1932–1936), however, was the first large-scale application of cement injections for stabilization and contributed decisively to the development of the existing knowledge for the time. A significant improvement in grout quality was provided by the colloidal mixer invented in 1934 by J.P. Morgan and was marketed in England in 1937 by Colcrete. The rapid mixing achieved, resulted in the removal of air from the grout, improved hydration and increased the amount of fine cement grains. This resulted in the possibility of making grouts with a lower water to cement ratio (W/C), with less exudation and higher strength. This type of mixer is still used today [11]. During World War II (1939-1945) there was, as expected, a slowdown of growth in the field of injections. After its end, however, a rapid progress was made, especially in the field of chemical solutions.

Very important is the invention of an acrylic chemical solution (AM-9) by Mello, Hauser and Lambe in 1953, which presented a slightly higher viscosity than water, had the ability to penetrate muddy soils and provided excellent curing time [12,13,14]. In the early 1980s, this solution was replaced by less toxic chemical solutions with AC-400 as their main representative. Soletanche in 1957 developed a “hard” silicate solution using an organic ester capable of delivering sand resistances of 2–3 MPa [12]. From 1980 onwards, a shift was realized in technological development, towards a limitation on the use of chemical solutions, along with the development of new non-toxic materials, consisting of inorganic components that are less harmful to the natural environment [12,15-19]. In this context, the effort to explore and develop new fine-grained cements, which were and are still widely used in injections, was included.

Suspension-type Grout Components

Suspension-type grouts can even be soil-water mixtures. These grouts are the most economical solution, but at the same time, they show many important disadvantages such as the inability to develop strength along with the difficulty of penetration. The most popular suspension - type grouts are those based on cement, whose main components are the common Portland cement and water. Depending on the needs of each application (high initial strength, resistance to chemical environment), it is possible to use different types of cement (aluminum, slag, etc.) instead of common cement. In addition, it is possible to add to the grouts some solids (sand, clay) with the main purpose of reducing the cost of injections, while the use of admixtures such as fly ash, slag silica fume and addition of chemical improvers (i.e. water reducers, superplasticizers, coagulation accelerators etc.) aims to improve some properties. The following sections list all the ingredients used in the manufacture of cement grouts and additionally indicate how they act on the properties of grouts.

Water

The quality of the water, used to make the cement grouts, should be controlled from the beginning because it is an important parameter of their composition. Generally, drinking water is considered suitable for the preparation of cement grouts [11]. According to Van der Stoel [12], the pH value is the regulatory factor based on which the choice should be made. This is based on the fact that the acidity of the water affects the setting time of the grouts. He argues, in fact, that when pH values range from 6 to 8, the effect of acidity is considered negligible. Also, water, which contains sulfates (> 0.1%), chlorine (> 0.5%), sugars, suspended solids especially organic, or presents a high alkali content, is dangerous, especially for applications with high strength requirements in the presence of steel.

Cement

Cement is a mortar, which, when mixed with water, can thicken and harden both in air and in water. It is mainly an excellent hydraulic mortar, which combines high hydraulicity and strength. Common Portland cements are mainly used for permeation grouting. The raw materials, which are necessary for the preparation of the main phases of Portland cements, are those that contain the oxides of calcium (CaO), silicon (SiO2), aluminum (Al2O3) and iron (Fe2O3). Limestone gives CaO, while clay gives SiO2, Al2O3 and Fe2O3. Marls contain all four oxides in varying amounts depending on their composition. Furthermore, silica sand contains SiO2 and bauxite Al2O3. The main phases of Portland type cements are the following [20]:

I. C3S silica

II. Calcium silicate C2S

III. C3A alumina

IV. Aluminum-iron calcium C2 (A, F)

The above phases are not present in the cements completely pure, but with small admixtures of MgO, TiO2, K2O, Na2O, Mn2O3 etc. Portland cement consists of clinker and gypsum (or gypsum and anhydride), which are collected in a very fine powder with a special surface of Blaine 2200-6000cm2/gr. The amount of gypsum that grinds together with the clinker depends on the fineness and type of cement and is necessary to regulate the setting. However, for reasons of volume stability, the amount of cement must be limited. Clinker is a product of firing (shells or extruders) of blast furnaces and the materials from which it is made are usually limestone and clay or marls that contain both materials. To improve the proportions of the firing mixture, silica sand and iron oxides can be added [20]. Cements have standard mechanical, chemical and physical properties, which are determined by performing standard tests.

According to the European Standard EN 197-1: 2000, these properties are strength after 2, 7 and 28 days, the initial setting time and the swelling after setting. Important properties of Portland cements are also Blaine fineness, density and lose weight. The most important property for choosing the right cement for injections is its fineness, which is expressed by the special Blaine surface (in cm2/gr and m2/gr). The finer the cement is ground, the larger the surface to react with water and therefore the reaction (hydration) takes less time. The cement grains react with the water on their surface and this reaction proceeds gradually towards the center, until the grain is completely hydrated. If the fineness is low, the cement grains are not fully hydrated, while in cements with very high fineness we have the appearance of cracks in the hardened cement paste. The German Regulations define only a lower limit (minimum limit) for fineness at 2200cm2/gr [20]. In general, in common Portland cements the fineness ranges from 350 to 800m2/gr [16].

However, the fineness is not enough to ensure the optimal choice of cement, but should be combined with the knowledge of its granulometric curve. Most common cements have a maximum grain diameter ranging from 50 to 200μm, thus limiting the scope of application of cement injections in coarse-grained soils with D10≥ 1 mm and k 5·10-2 cm/sec and in rocks presenting cracks of thickness α ≥ 160μm [21]. Due to these limitations, arose the need for the production of new fine-grained cements that would be the basis for the preparation of grouts with improved properties, able to penetrate into finer formations. In the following paragraphs, issues related to the aforementioned materials are developed in detail.

Additives

The term additives refers to natural or artificial materials that are added to cement grouts to improve certain properties and/or reduce their manufacturing costs. In the international literature they appear under various terms and mainly with the term “fillers” and are divided into non-active materials that are inert (sands, clays) and pozzolans and chemical property improvers that are active ingredients [21-24].

Fine-Grained Cements

Common cement-based suspensions -as defined by the various standards (ASTM C 150-04, EN 197-1: 2000, etc.)- are capable of penetrating coarse-grained soil materials effectively (e.g. gravel and coarse-grained sands) with a permeability of 10- 1cm/sec and above [25]. Various types of chemical solutions are used to reinforce lower permeability soils (up to 10-4cm/sec) that can penetrate into soil formations such as fine sands and sludges. However, it has been shown that materials of this type have significant disadvantages, such as high cost, unsatisfactory durability, low strength and can also cause environmental pollution due to their toxicity [14,25-27]. In the last thirty years, new materials have been developed, which are presented as a counter-proposal to the use of chemical solutions for the above problems. These are extremely fine-grained cements whose suspensions have the ability to penetrate and reinforce even fine-grained sands [17,28-34]. The main advantage of these materials over chemical solutions is that they are composed entirely of minerals and thus do not cause adverse environmental effects.

Definition

For the reinforcement of soils, characterized as medium or fine-grained sands, various types of solutions have been developed in the last thirty years that are able to penetrate effectively into soil formations with a permeability coefficient of up to 10-4cm/ sec. These solutions, which are mainly chemical, have significant disadvantages associated with high cost, unsatisfactory durability and environmental impact due to their toxic behavior [13,25,26]. On the other hand, mortars developed based on common cements can penetrate effectively into coarse-grained soils (e.g. gravelly and coarse-grained sands) with a permeability of 10-1cm/sec [25]. Therefore, in order to achieve satisfactory penetration with the least possible impact on the natural environment, the use of fine-grained cements for the preparation of suspensions that are capable to permeate fine-grained formations has been proposed in recent years [9,17,28].

Categorization of fine-grained cements

The categorization of cements into “fine-grained” along with their clear separation is based on the establishment of certain criteria and standards that are applied. The Norwegian standard separates the fine-grained cements into: microfine with d95 <30μm and ultrafine with d95<15μm [23]. In the USA, according to the ACI Committee 552, fine-grained cements are those that show a maximum grain size, dmax=15μm [35], while the European standard EN 12715: 2000, defines as fine-grained (microfine cements) those with d95 <20 μm and Blaine fineness > 8000cm2/ gr. Finally, in Britain, ultrafine cements are defined those having a maximum diameter of grain dmax< 6μm [11].

Methods of preparation

The preparation of suspensions from fine-grained cements is carried out by two methods: the dry and the wet grinding process [36]. Most fine-grained cements are produced by the dry method and are products of grinding Portland common cement, blast furnace slag or some pozzolan. Grinding takes place in special mills, in which the size of the maximum grain is reduced [24]. The second method of making fine-grained cements, referred to in the literature as the wet method, and grinds the cement in mills in the presence of water, on site.

Efforts in this direction have led to the production of suspensions called Microsol [25] and Cemill [27], although there are other standard methods of preparing suspensions, such as Ahrens (1997) [38] and Huang et al. (2002) [36]. However, Cemill suspensions appear to have a very short workability and require a complex manufacturing process, while Ahrens suspensions do not exhibit satisfactory rheological properties and result from extremely slow process [24]. Naudts and Landry in 2003 [39] introduced the PASREM grinding machine which enables the preparation of suspensions in a short period along with satisfactory rheological properties. In general, the wet method allows the production of the desired amount of suspension by reducing waste favors more accurate project budgets and requires much lower costs compared to the preparation of fine-grained cements with the dry method. However, it does not allow the production of materials with a maximum grain size of less than 18μm [39].

Fine-grained cements as commercial products

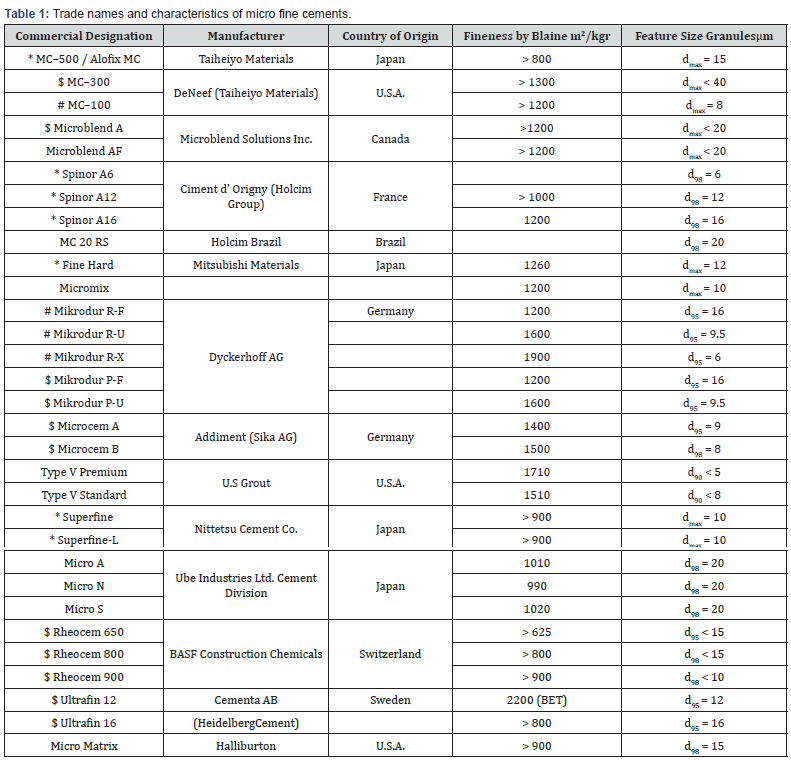

A significant number of commercially available fine-grained cements has been developed in recent years. Specific information on the production method and composition of these fine-grained cements is not available from the producers. Table 1 below gives the trade names of some fine-grained cements and their characteristics, based on the existing information from the international literature. The MC-500 is the oldest fine-grained cement in the international literature and is produced by the Japanese cement company Onoda Cement. Following the absorption of the company by Taiheiyo Materials, this product is available in the market of Southeast Asia and Australia under the brand name Alofix MC, while in the USA under the name MC- 500. It is a mixture of finely ground Portland cement and slag in a ratio of 4:1 [40], which consists only of minerals and has a specific gravity of 3.0±0.1 gr/cm3.

Cement based on: $ Portland, # slag, * Portland + slag

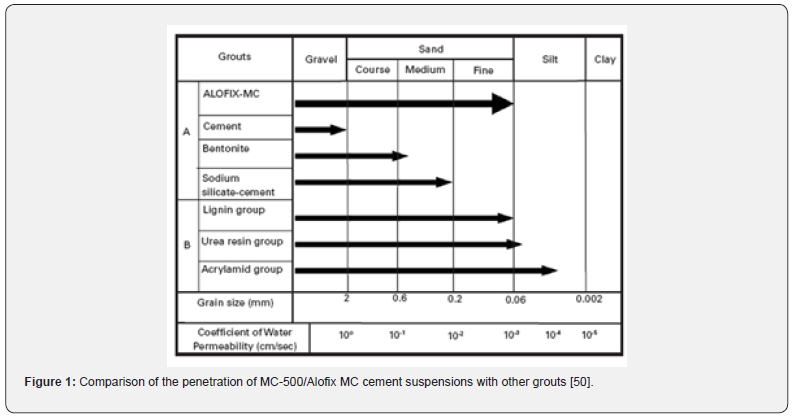

Its manufacturers recommend its combined use with the NS- 200 hyper plasticizer at a dose of 2% by weight of dry cement. From Figure 1 it yields that MC-500/Alofix MC based cement suspensions can achieve penetration comparable to that of chemical solutions. SuperFine and SuperFine-L are fine-grained, slag cements manufactured by the Japanese company Nittetsu. They have an average grain size of 3μm and a specific gravity of 3.0gr/cm3 and 2.92gr/cm3, respectively [19]. Several researchers [41-43] have reported the use of Nittetsu SuperFine. Clarke introduced later the MC-500 to the U.S.A. under the trade name M5 and then manufactured M1 and M3 cements [44-46], giving them the trade names MC-100 and MC-300 respectively. MC-100 is a fine-grained slag, while MC-300 is a fine-grained Portland cement [47-49].

The U.S. Company Grout prepares cement-based injection materials by both dry and wet methods. The fine-grained cements Type V Premium and Type V Standard have a specific weight of 2.63gr/cm3 and 2.70gr/cm3 and an average grain size of 2.50μm and 4.0μm, respectively. Their chemical composition includes 55% Thera earth and 45% super grounded type IV Portland cement. In the dry state, their combined use with a hyper plasticizer in doses of 1.5% and 2.5% by weight respectively of dry cement is required. The specific materials are the basis for the production of suspensions with a ratio W/C of 0.6:1 and 0.8:1, respectively, following the wet method and a very specific process in terms of the manner and time of mixing and stirring. The use of Type V Premium cement is noted in their research efforts by Henn et al., (2001) [41] and Henn et al., (2005) [42].

Important references in the international literature are related to the Spinor cements (A6, A12 and A16) of the French company Soletanche-Bachy [15,51]. Their main representativeis the fine-grained cement A12, which is slag having a specific weight of 2.94gr/cm3. The manufacturer proposes the use of a superplasticizer in a dosage of 3% by weight of dry cement along with W/C ratios from 1:1 to 3:1. Spinor A12 can also be used for the preparation of Microsol grouts, which are prepared by the wet method. It is also reported that MC 20 RC fine cement is manufactured in Brazil by Holcim Brazil [52]. A significant part of the international market is occupied by fine-grained cements under the brand name Mikrodur, which are sold by Dyckerhoff AG. These are products consisting of either pure Portland (with the mark P) or pure slag (with the mark R). Finosol products are also available from the same company, which are suspensions resulting from the mixing of blast furnace slag, clinker, coagulation and admixtures controller in field applications.

Characteristic of these suspensions is the individual preparation of their ingredients before the final mixing. Depending on their fineness, Mikrodur and Finosol materials are divided into F (Fine), U(Ultrafine) and X(EXtrafine). Mikrodur and Finosol cements have been used in various research efforts [25,53-54]. Products of the company BASF Construction Chemicals are the fine-grained cements under the brand name Rheocem, which are based on pure Portland cement. Depending on their fineness, they are divided into products 650, 800 and 900 [55]. The manufacturer recommends their use in combination with the plasticizer Rheobuild 2000PF in a dosage ranging from 1.0% to 3.0% by weight of dry cement. Henn et al. (2001) [41], used in field applications, suspensions based on the fine-grained Microcem A and Microcem B cements of Addiment company. These fine-grained pure Portland cements have a specific weight of 3.20gr/cm3. The Swedish company Cementa AB is also active in the production of fine-grained cements, introducing on the market the fine-grained cements Ultrafin 12 and Ultrafin 16 with a specific weight of 3.10 - 3.20gr/cm3.

The Norwegian company Elkem ASA Materials proposes the product Ultrafin 12 as a basis for the preparation of fine-grained suspensions available in the market under the brand name MultiGrout System. The Cemill designation identifies the wet method by which cement suspensions are prepared on site using Portland conventional cement as a base. The method was proposed by De Paoli et al. (1992b) [37] and aims at developing an on-site production process of fine-grained material using common cement. This process made it possible to produce not only unstable grouts (Cemill-I), but also fixed grouts using bentonite (Cemill-S). These objectives were achieved with a special device, which has two functions:

a) achieves very strong dispersion of cement granules without the addition of a corresponding anticoagulant and

b) implements a progressive procedure of elaborating the coarse cement fraction until it reaches the desired levels of fineness without the need for this coarse material to be removed [37].

Regarding the chemical composition of fine-grained cements, it is emphasized that, mainly, they consist of the same oxides as Portland cements, but in different proportions. Another element, which promotes the use of fine-grained cements for permeation injections, is the fact that they are composed of inorganic and non-toxic materials, an element that is particularly beneficial in preventing environmental pollution. Table 2 below gives typical chemical compositions of commercially available fine-grained cements, while Table 3 lists characteristic cases of use for fine-grained cement grouts.

Conclusion

i. The improvement of properties and the mechanical behavior of soil formations can be achieved on the spot by performing an appropriate injection program. The injection program may: (a) be performed as a part of the preliminary field work prior to the commencement of a project’s construction, (b) be a part of the construction of the main project, or (c) be designed and executed as a “treatment” when unforeseen circumstances arise during the construction of a project.

ii. Injections are generally intended either to increase the shear strength, density and stiffness of the soil or to reduce compressibility and permeability.

iii. The grouts used to make permeation injections are mainly suspensions and chemical solutions.

iv. The suspensions penetrate satisfactorily in soils with granulometry up to coarse sand.

v. Chemical solutions penetrate satisfactorily in more fine-grained formations up to fine-grained sands or coarse-grained sludges.

vi. Because some chemical solutions are toxic or generally harmful to the environment and humans, an effort has been made internationally in recent years to replace them with inorganic fine-grained cement-based suspensions.

Funding

The research effort reported herein is part of the research project (PENED) which is co-financed by E.U. – European Social Fund (80%) and the Greek Ministry of Development-GSRT (20%).

References

- Philotheos Lokkas, Emmanouil Papadimitriou, Nikolaos Alamanis, Grigorios Papageorgiou, Dimitrios Christodoulou, et al. (2021) Significant Foundation Techniques for Education: A Critical Analysis. WSEAS Trans Adv Eng Educ 18: 17-26.

- Philotheos Lokkas, Ioannis Chouliaras, Theodoros Chrisanidis, Dimitrios Christodoulou, Emmanouil Papadimitriou, et al. (2021) Historical background and evolution of Soil Mechanics. WSEAS Transactions on Advances in Engineering Educ WSEAS Trans Adv Eng Educ ation 18: 96-113.

- Nikolaos Alamanis (2017) Failure of Slopes and Embankments under Static and Seismic Loading. Ame Scie Res J Eng Tec Sci 35(1): 95-126.

- Papageorgiou G P, Alamanis N, Xafoulis N (2020) Acceptable movements of road embankments. Elect J Stru Eng 20(1): 30-32.

- Alamanis Nikolaos, Zografos Christos, Papageorgiou Grigorios, Xafoulis Nikolaos, Chouliaras Ioannis (2020) Risk of retaining systems for deep excavations in urban road infrastructure with respect to work staff perception. Inter J Sci Tech Res 9(2): 4168-4175.

- Dimos Zachos, Georgios Bakalis, Konstantinos Bakalis, Nikolaos Alamanis, Grigorios Papageorgiou, et al. (2021) A methodology for selecting the required cross‑section of a self‑supporting retaining bulkhead, on a vertical excavation front, of an energy conduit passage trench. Ener Sys 12: 989-1002.

- Alamanis N, Dakoulas P (2019) Simulation of random soil properties by the Local Average Subdivision method and engineering applications. Energy Systems.

- Alamanis N, Dakoulas P (2021) Effect of spatial variability of soil properties on permanent seismic displacements of slopes with uniform load. 14th Baltic Sea Geotechnical Conference 18-19.

- Atmatzidis D K (1990) Soil improvements with injections. University Notes, University of Patras, Patras, Greece.

- Sudheer Kumar G, Sumanth M K, Madimi S (2020) A review paper on stabilization of sandy soil by using cement grouting technique. J Cri Rev 7(14): 902-908.

- Littlejohn S (2003) The development of practice in permeation and compensation grouting: A historical review (1802-2002): Part 1 Permeation Grouting. Proceedings of the 3rd International Conference on Grouting and Ground Treatment, Johnsen F L, Bruce A D, Byle J M, New Orleans La, U S A, ASCE, New York, U S A Geotechnical Special Publication 120(1): 50-97.

- Van der Stoel A E C (2001) Grouting for pile foundation improvement. Technische Universiteit Delft, DUP Science.

- Karol R H (1985) Grout penetrability. Proceedings, Issues in Dam Grouting In: Baker W H, Denver, Colorado, USA, ASCE, New York, USA pp 27-33.

- Karol R H (1982) Chemical grouts and their properties. Proceedings, Conference on Grouting in Geotechnical Engineering, Baker W.H., Editor, New Orleans, Louisiana, USA, ASCE, New York, USA pp 359-377.

- Saada Z, Canou J, Dormieux L, Dupla J C, Maghous S (2005) Modelling of cement suspension flow in granular porous media”, Inter J Num Anal Meth Geomec 27(7): 691-711.

- Bruce A D, Littlejohn S, Naudts C A (1997) Grouting materials for ground treatment: A practitioner's guide In: Vipulanandan C(Ed), Geotechnical Special Publication, ASCE, New York, USA pp 66: 306-334.

- Arenzana L, Krizek R J, Pepper S F (1989) Injection of dilute microfine cement suspensions into fine sands. Proceedings of the International Conference on Soil Mechanics and Foundation Engineering, In: A A Balkema (Ed) Rotterdam, Netherlands pp 2: 1331-1334.

- Eriksson M, Stille H (2003) A method for measuring and evaluating the permeability of grouts. Proceedings of the 3rd International Conference on Grouting and Ground Treatment. In: Johnsen F L, Bruce A D, Byle J M (Eds) Geotechnical Special Publication, New York, USA pp. 1326-1337.

- Weaver K D (1991) Dam Foundation Grouting. ASCE, New York, USA.

- Sideris K (1998) Technology of building material, Democritus University of Thrace, Xanthi, Greece.

- Markou I N (1995) Grinded Greek lignite fly ash as a suspension-type injection material for on-site soil improvement, University of Patras, Greece.

- Littlejohn G S (1982) Design of cement-based grouts. Proceedings, Conference on Grouting in Geotechnical Engineering In: Baker W H (Ed), ASCE, New York, USA 1: 35-48.

- Tolpannen P, Syrjanen P (2003) Hard rock tunnel grouting practice in Finland, Sweden, and Norway: Literature study. Technical Report, Finnish Tunnelling Association.

- Naudts A, Landry E, Hooey S, Naudts W (2003) Additives and admixtures in cement-based grouts. Proceedings of the 3rd International Conference on Grouting and Ground Treatment. In: Johnsen F L, Bruce A D, Byle J M (Eds) ASCE, Geotechnical Special Publication, New York, USA pp. 1180-1191.

- Legendre Y, Hery Ph, Vattement H (1987) Microsol grouting, A method for grouting fine alluvium. Proceedings, 6th International Conference Offshore Mechanics and Arctic Engineering Symposium, ASCE, New York, USA pp. 433-440.

- Shimoda M, Ohmori H (1982) Ultrafine grouting material. Proceedings, Conference on Grouting in Geotechnical Engineering. In: Baker W H (Ed), ASCE, New York, USA pp. 77-91.

- Dupla J C, Canou J, Gouvenot D (2004) An advanced experimental set-up for studying a monodirectional grout injection process. Gro Impro 8(3): 91-99.

- Clarke W J (1984) Performance characteristics of microfine cement. ASCE Preprint 84-023, Atlanta, USA pp 1-14.

- Dano C, Hicher P Y, Tailliez S (2004) Engineering properties of grouted sands. J Geotec Geoenviron Eng 130(3): 328-338.

- Christodoulou D N, Droudakis A I, Pantazopoulos I A, Markou I N, Atmatzidis D K (2009) Groutability and Effectiveness of Microfine Cement Grouts. Proceedings, 17th International Conference on Soil Mechanics and Geotechnical Engineering: The Academia and Practice of Geotechnical Engineering. In: Hamza et al. (Eds) IOS Press, Egypt pp 2232-2235.

- Pantazopoulos I A, Markou I N, Christodoulou D N, Droudakis A I, Atmatzidis D K, et al. (2012) Development of microfine cement grouts by pulverizing ordinary cements. Cem Conc Comp 34(5): 593-603.

- Markou I N, Christodoulou D N, Petala E S, Atmatzidis D K (2018) Injectability of Microfine Cement Grouts into Limestone Sands with Different Gradations: Experimental Investigation and Prediction. J Geotec Geoenviron Eng 36(2): 959-981.

- Markou I N, Christodoulou D N, Papadopoulos B K (2015) Penetrability of microfine cement grouts: experimental investigation and fuzzy regression modeling. Can Geotech J52(7): 868-882.

- Mollamahmutoglu M (2003) Treatment of medium to coarse grained sands by fine grained Portland cement (FGPC) as an alternative grouting material to silicate-ester grouts. Cem Conc Aggre 25(1): 1-6.

- Perret S, Palardy D, Ballivy G (2000) Rheological behavior and setting time of microfine cement-based grouts. ACI Materials J 97(4): 472-478.

- Huang Z, Chen M, Chen X (2002) A developed technology for wet-ground fine cement slurry with its applications. Cem Conc Res 33: 729-732.

- De Paoli B, Bosco B, Granata R, Bruce D A (1992b) Fundamental observations on cement based grouts (2): Microfine cements and the Cemill process. Proceedings, Conference on Grouting, Soil Improvement and Geosynthetics. In: Borden R H, Holtz R D, Juran I (Eds), ASCE, Geotechnical Publication, New York, USA pp 486-499.

- Ahrens H E (1997) A new and superior ultrafine cementitious grout. Proceedings, Conference on Grouting: Compaction, Remediation, Testing. In: Vipulanandan C (Ed), ASCE, Geotechnical Special Publication, New York USA pp 188-196.

- Naudts A, Landry E (2003) New on-site wet milling technology for the preparation of ultrafine cement-based grouts. Proceedings of the 3rd International Conference on Grouting and Ground Treatment. In: Johnsen F L, Bruce A D, Byle J M (Eds), ASCE, Geotechnical Special Publication, New York, USA pp 1200-1207.

- Bruce D A (1992) Trends and developments in American grouting practice. Proceedings, Conference on Grouting in the Ground. In: Bell A L (Ed) Thomas Telford, London, England, pp 573-589.

- Henn R, Ganse P, Bandimere S, Smoak G, Warner J (2001) Comparison of penetration test results of grouts made with various ultrafine cement products. Proceedings of the Rapid Excavation and Tunneling Conference, Elsevier Science. In: B V Amsterdam pp 345-361.

- Henn R, Davenport R (2005) Ultrafine cement: A critical component of a grouting program. Tunn Tunne Interna 27-29.

- Brachman R W I, Martin C D, Gilliss S A (2004) Grout field trials in outwash sands. Canadian Geotech J 41(1): 1-11.

- Clarke W J, Boyd M D, Helal M (1992) Ultrafine cement tests and dam test grouting. Proceedings, Conference on Grouting, Soil Improvement and Geosynthetics. In: Borden RH, Holtz R D, Juran I (Eds) ASCE, Geotechnical Publication, New York, USA pp 626-638.

- Clarke W J, Boyd M D, Helal M (1993) Ultrafine cement tests and drilling Warm Spring Dam. Proceedings, Geotechnical Practice in Dam Rehabilitation, Specialty Conference. In: Anderson LR (Ed) ASCE, Geotechnical Publication, New York, USA 35: 718-732.

- Clarke W J, McNally A C (1993) Ultrafine cement for oil well cementing. Rocky Mountain Regional Meeting/Low Permeability Reservoirs Symposium and Exhibition, Society of Petroleum Engineers (SPE), Richardson, TX, United States, pp 291-298.

- Weaver K, Coad R M, McIntosh K R (1992a) Grouting against hazwaste. Civil Engineering. ASCE, New York, USA pp 70-72.

- Helal M, Krizek R J (1992) Preferred orientation of pore structure in cement-grouted sand. Proceedings, Conference on Grouting, Soil Improvement and Geosynthetics. In: Borden RH, Holtz RD, Juran I (Eds) ASCE, Geotechnical Publication, New York, USA pp 526-540.

- Schwarz L G, Krizek R J (1992) Effects of mixing on rheological properties of microfine cement grout. Proceedings, Conference on Grouting, Soil Improvement and Geosynthetics. In: Borden RH, Holtz RD, Juran I (Eds) ASCE, Geotechnical Publication, New York, USA pp 512-525.

- Bouchelaghem F, Vulliet L (2001) Mathematical and numerical filtration-advection-dispersion model of miscible grout propagation in saturated porous media. Intern J Nume Anal Met Geomech 25: 1195-1227.

- Abreu J V, Mezzalira F A, Cruz L O M (2005) Brazilian special cements for shotcrete and injections in underground constructions. Proceedings, Conference on Waterproofing, ITA-AITES, Sao Paulo, Brazil.

- Hakansson U, Hassler L, Stille H (1992) Rheological properties of microfine cement grouts with additives. Proceedings, Conference on Grouting, Soil Improvement and Geosynthetics. In: Borden RH, Holtz RD, Juran I (Eds) ASCE, Geotechnical Publication, New York, USA pp 551-563.

- Reinhardt H W (1993) Ultra-fine cements for special applications. Adv Cem Bas Mate 1: 106-107.

- Mittag J, Savvidis S (2003) The groutability of sands - results from one-dimensional and spherical tests. Proceedings, 3rd International Conference on Grouting and Ground Treatment. In: Johnsen FL, Bruce AD, Byle JM (Eds) ASCE, Geotechnical Special Publication, New York, USA pp 1372-1382.

- Mollamahmutoglu M, Yilmaz Y, Kutlu I (2007) Grouting performance of microfine cement and silica fume mix into sands. J ASTM Intern 4(4).