The Synergism of a Novel Thermostable Acetyl Xylan Esterase with Cellulase Degrade Wheat Straw

Xiaoshen Zhao1,2*, Jin Xu1,2, Liyang Liu3, Zujun Deng1,2, Shan Liu4, Jeonyun Yun4, Xiong Xiao4 and He Li 1,2*

1School of Life Sciences and Biopharmaceuticals, Guangdong Pharmaceutical University, China

2Guangdong Key Laboratory of Bioactive Drug Research, China

3Business School of Medicine, Guangdong Pharmaceutical University, China

4Guangzhou Yachun Cosmetics Manufacturing Co., Ltd, China

Submission: November 19, 2020;Published: December 04, 2020

*Corresponding author: He Li, School of Life Sciences and Biopharmaceuticals, Guangdong Pharmaceutical University, Guangzhou, China and Guangdong Key Laboratory of Bioactive Drug Research, China

How to cite this article: Xiaoshen Z, Jin X, Liyang L, Zujun D, et al. The Synergism of a Novel Thermostable Acetyl Xylan Esterase with Cellulase Degrade Wheat Straw. Organic & Medicinal Chem IJ. 2020; 10(2): 555785. DOI: 10.19080/OMCIJ.2020.10.555785.

Abstract

Acetyl xylan esterase is one of the key enzymes in xylan degradation enzyme system. However, acetyl xylan esterase from natural microorganisms has low expression, low enzyme activity and impure product. In this study, a new xylanase gene, est1051, from the metagenomic library, was expressed in prokaryotic system. Enzymatic properties, including optimum temperature and pH, thermal and pH stability, organic solvent, metal ion and salt solution tolerance were explored. Finally, the synergism with cellulase on degrading straw was identified and evaluated. EST1051 displayed high homology with acetyl xylan esterases in amino acid sequences and conserved active sites. And EST1051 showed good stability across a broad temperature range, its enzymatic activities had been retained more than 50% between 4℃ and 50℃ after 24 hours of incubation. Furthermore, we conducted single-factor analysis and orthogonal design to determine optimal conditions for the highest reducing sugar yield of wheat straw. Interestingly, the synergism of EST1051 with cellulase showed the efficient transformation of wheat straw. In conclusion, these findings might open the door to significant industrial applications of a novel acetyl xylan esterase (NCBI Reference Sequence: MK111431, EST1051) and help identify more efficient methods to degrade cellulose-rich plants.

Keywords:Acetyl xylan esterase; Fermentation condition optimization; Straw degradation

Introduction

Acetyl xylan esterase (AXE, EC 3.1.1.72) is one of the least known hemicellulose degrading enzymes. It is found that the acetyl group hinders the hydrolysis of xylanase to xylan. Deacetylation of acetylated xylan can improve its hydrolysis efficiency. Therefore, deacetylation of acetylated xylan, as carbon source, has been widely used for microbial growth in past long time. However, the ability of the microorganism to produce AXE is inhibited under this condition. Moreover, the discovery and research of this enzyme are relatively late than other lignocellulose degrading enzymes due to the lack of suitable substrate and low content. AXE has same conserved sequence, G-X-S-X-G [1], as serine esterase family. The substrate binding site of AXE is very small and can only contain one acetyl group. Thus, the specificity of the enzyme is maintained [2,3]. As far as we know, although many acetyl xylanases [4,5,6] have been reported, they are difficult to be used in industry due to their lack of stability and activity. The thermostable AXE with excellent properties still needs to be discovered.

Nonrenewable resources are gradually exhausted, which has caused serious environmental pollution problems [7]. The demand for renewable resources development and utilization in the world is increasing [8]. With the continuous progress of Chinese agriculture, the total output of crop straw is also increasing year by year. However, only a small part of the crop straw is used for returning to the field, a part of the crop straw is used as feed, and only a very small number of applications in industry [9], the rest is directly burned. Cellulose, lignin, and hemicellulose are the main components of straw, among which the content of the hemicellulose accounts for about 30% [10]. Hemicellulose is the second largest renewable biomass resources after cellulose in plant cell walls [11]. The original soluble sugar and hydrolyzed small molecular sugar in hemicellulose can be further fermented into ethanol [12]. Hemicellulose also contains a variety of side chains together with various side chains of lignin. Cellulose is wrapped inside so that the accessibility of cellulose and enzymes is reduced. Therefore, degradation of hemicellulose can also improve the utilization of cellulose.

Synergism of acetyl xylanase and cellulase can effectively improve the conversion rate of biomass sugar, which can reduce the cost of biofuel. Treatment of hemicelluloses by organic solvents or other non-biological methods will result in large loss of hemicellulose with high energy consumption and high cost of equipment. Therefore, enzymatic treatment of hemicellulose is a feasible, green, and reasonable way. Some studies on enzymatic degradation of straw have been reported. using. The maximum sugar yield reaches 23.48mg/ml when crude enzyme complex of T. reesei Rut-C30 and AXE transformant T2 react with corn stover plus paddy straw mix (1:1 ratio) after 96h [13]. The maximum sugar yield reaches 1.6umol/ml when immobilized enzyme, PersiXyn2@bis-AE@RKIT-6, reacts with rice straw after 50h [14]. In this work, the saccharification rate reached 76.12% when EST1051 and cellulase reacted with wheat straw pretreated by alkali for 8h.

In this study, EST1051 was sequenced and then performed multiple sequence alignment. The results diaplayed that it was a novel AXE. And EST1051 showed excellent thermal stability and tolerance to metal ions, organic solvents, salt solutions and excellent ability to degrade wheat straw and great potential for industrial application.

Results and Discussion

Genetic characterization

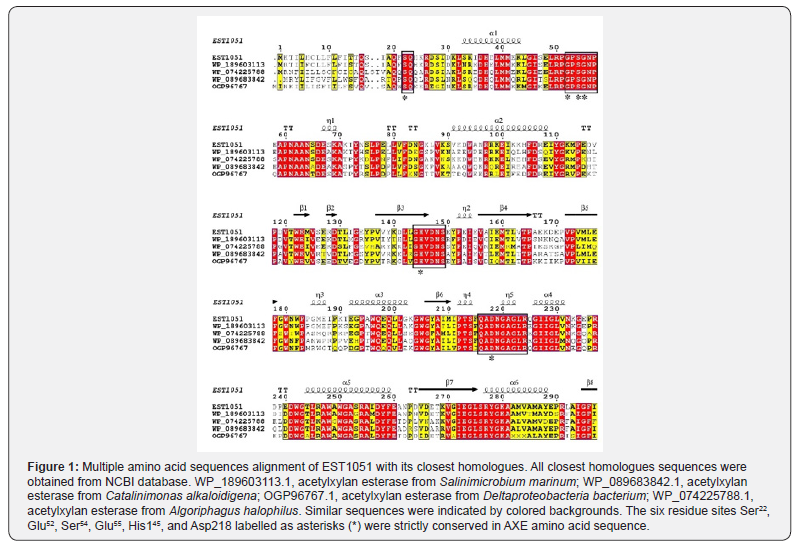

The est1051 was sequenced and analyzed with ORFfinder of the National Center for Biotechnology Information (NCBI), which showed that the full length of the ORF sequence is 1051 bp containing AXE gene named est1051. The est1051 encoded a 35.07 kDa protein containing 307 amino acids. Through multiple sequences alignment and protein BLAST search by BioEdiet , ESPript 3.0 and NCBI, EST1051 was found to be similar to an acetylxylan esterase (81.40%, NCBI accession: WP_189603113.1), an acetylxylan esterase (67.24%, NCBI accession: WP_089683842.1), an acetylxylan esterase (66.55%, NCBI accession: OGP96767.1), an acetylxylan esterase (64.69%, NCBI accession: WP_074225788.1). These sequences were strictly conserved with G-X-S-X-G and catalytic triad Ser22-His145-Asp218 (Figure 1). The catalytic triad formed the catalytic active center of AXE. Through multiple sequences alignment, it could be concluded that EST1051 was a new AXE (EC3.1.1.72).

Cloning and overexpression of the AXE Gene in E. coli and purification of the recombinant protein

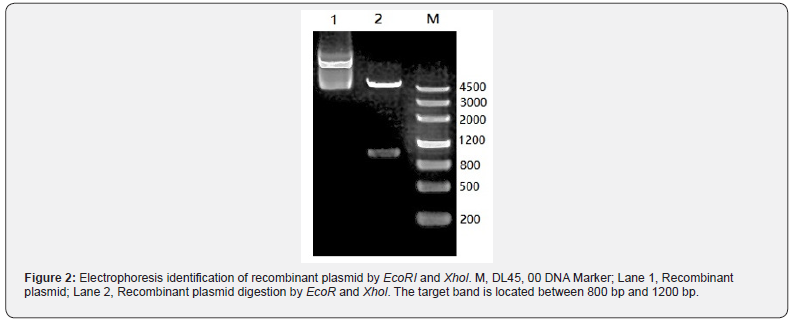

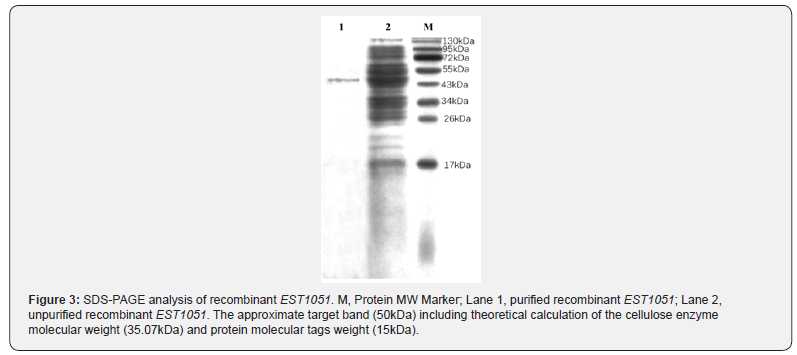

PCR was conducted by using plasmids containing pUC118- Est1051 and Est1051-F, Est1051-R as templates and primers respectively. The amplified fragment length was consistent with the predicted target DNA fragment length of 1051 bp. pET28aest1051 was identified by enzyme digestion verified (Figure 2) and DNA sequencing confirmed. EST1051 was expressed in E. coli BL21 (DE3). According to the optimal induced temperature (37℃) and time (10h), the optimal induction concentration of isopropyl β-D-1thiogalactopyranoside (IPTG) was 0.8 mM. Expression strain was induced by IPTG and then broken by ultrasound. The crude enzyme was purified and then analyzed by SDS-polyacrylamide gel electrophoresis (SDS-PAGE) [15]. The enzyme was purified with a specific activity of 1046±17 U/mg. Figure 3 showed the results, the approximate target band (50kDa) including theoretical calculation of the cellulose enzyme molecular weight (35.07kDa) and protein molecular tags weight (15kDa). The results showed that the recombinant protein was high soluble expression in E. coli, which was also the premise and basis for industrial application.

Characterization of recombinant EST1051

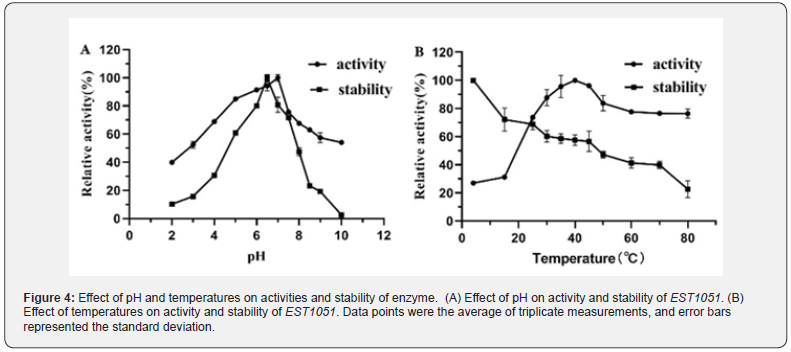

EST1051 displayed an optimal pH of 7.0 toward ρ-nitrophenyl acetate (ρNP-C2), indicating that AXE EST1051 was a alkali resistant enzyme (Figure 4A). The enzyme activity could still maintain above 50% between pH 5-7.5 after 24 h. The optimal reaction temperature of EST1051 at optimal pH was measured with ρNP-C2 as substrate (Figure 4B). Maximum activity occurred at 40℃. And more than 50% of maximum activity was retained at 4℃–50℃ after 24 h, indicating that cellulase Cel1029 has good tolerance to temperature.

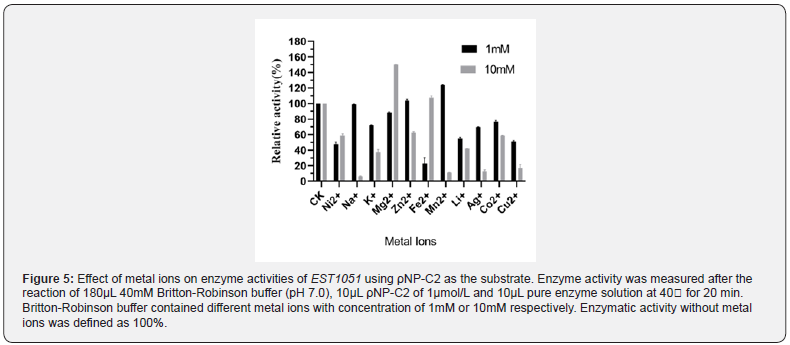

As shown in Figure 5. AXE activity was slightly enhanced in the presence of Zn2+, Mn2+ and Mg2+, Fe2+ at a concentration of 1mM and 10mM respectively. And AXE activity was obviously enhanced by the addition of Mg2+ at concentration of 10mM with the relative activity 150.46%. The result suggested that metal ions were required for enzyme activity and EST1051 was resistant to most metal ions. The enzyme activity could be increased by adding appropriate metal ions in industrial production.

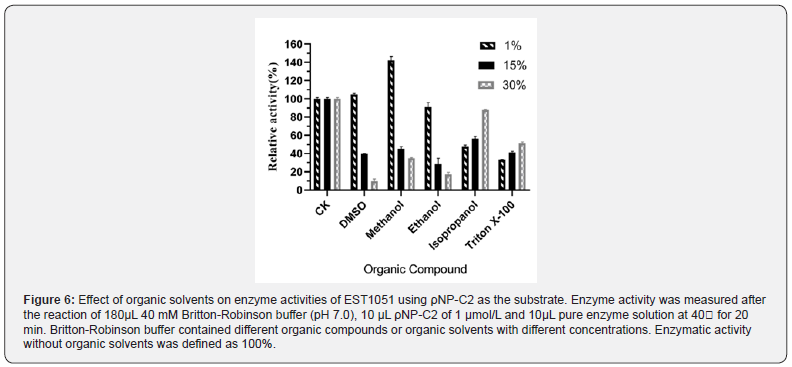

To determine the usefulness of est1051 in industrial applications, it was necessary to study the effects of organic solvents and high salt on its activity and stability. Fig. 6 shows the results. The relative activity was maintained at around 91.01% in the presence of 1 mM ethanol. AXE activity increased slightly in the presence of 1 mM DMSO or methanol with relative activities 105% and 141.89% respectively. Interestingly, with the increase of the concentration of isopropanol and Triton X-100, the enzyme activity increased, and the enzyme activity could reach 87.80% in 30% isopropanol.

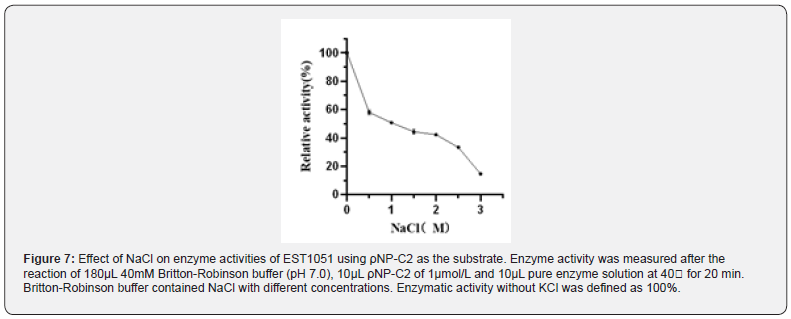

NaCl (0M to 2M) were used to study the salt tolerance of recombinant enzyme properties under optimal temperatures and pH. Figure 6 shows the results for the enzyme activity, which remained above 50% when the salt concentration was lower than 1 M, indicating that EST1051 tolerated low concentrations of salt. In summary, AXE EST1051 tolerated some organic compounds and reagents. The addition of different concentrations of certain organic compounds increased enzyme activity.

As shown in Fig. 5, AXE activity was slightly enhanced in the presence of Zn2+, Mn2+ at 1 mM, and by Mg2+, Fe2+ at a concentration of 10 mM, with other relative activities. For Mg2+, at 10 mM had the greatest promoting on the enzyme, and the relative enzyme reached 150.46%. The relative activity of AXE was inhibited by other metal ions in different degrees.

To determine the usefulness of est1051 in industrial applications, it is necessary to study the effects of organic solvents and high salt on its activity and stability. Fig. 6 shows the results. The relative activity was maintained at around 91.01% in the presence of 1 mM of ethanol. AXE activity increased slightly in the presence of 1 mM of DMSO and methanol, with relative activities ranging from 105% to 141.89%. Other concentrations of organic solvents have different degrees of inhibition in relative activity. Interestingly, the enzyme activity was promoted with the increase of the concentration of isopropanol and Triton X-100, and the enzyme activity could reach 87.80% in 30% isopropanol. This result suggested that EST1051 had strong tolerance to organic solvents. And even adding appropriate organic solvents in industrial production might increase the enzyme activity.

NaCl (0 M to 2 M) were used to study the salt tolerance of recombinant enzyme properties under optimal temperatures and pH. Figure 7 shows the results. The enzyme activity remained above 50% when the salt concentration was 1M, indicating that EST1051 tolerated low concentrations of salt. In this study, The Km and Vmax values were 0.923mM and 0.061mM/min, respectively. The kinetic constants Km and Vmax of AXE were determined using ρNP-C2 as substrate. Km was the most important characteristic constant of enzyme. Determining Km is an important method to study enzyme kinetics, which can reflect the size of affinity between enzyme and substrate.

Enzymatic Hydrolysis of Wheat Straw Biomass

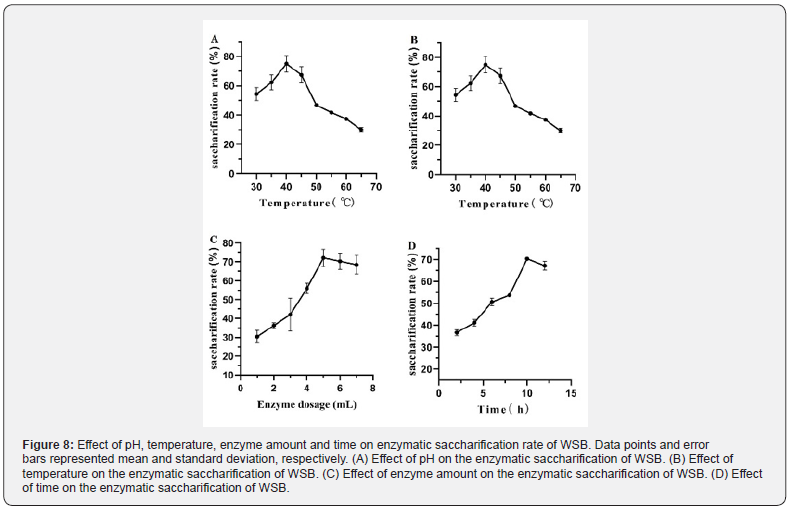

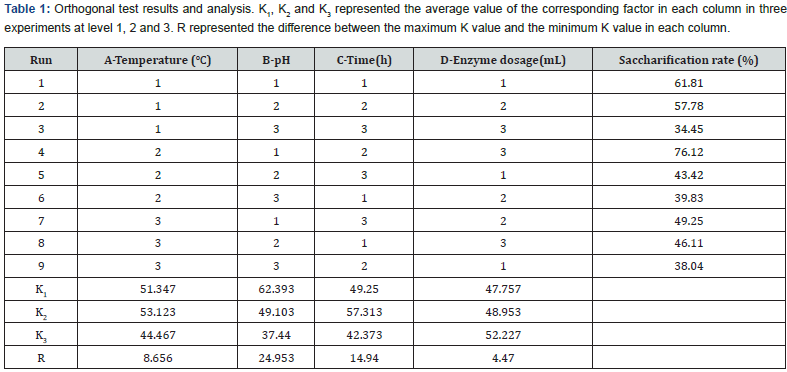

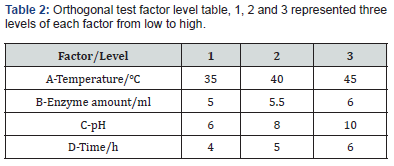

Wheat straw biomass contain a large amount of cellulose, lignin, and hemicellulose, which are hydrolyzed into cellobiose or glucose by enzymes such as cellulase and xylan esterase. Cellulase and AXE can degrade cellulose, lignin and hemicellulose to produce cellulosic ethanol, and then produce biofuel by microbial fermentation, which can optimize the use of WSB as a resource [16,17]. The optimal conditions of enzymatic hydrolysis to WSB were studied by using spectrophotometry. Figure 8 showed the optimal hydrolysis conditions. The saccharification rate reached 72.58% at a pH of 6 (Figure 8A). As pH increase, the saccharification rate decreased. At a pH of 7.5, the saccharification rate was only 42.08%. At 65℃, the saccharification rate dropped to its lowest value of 29.96%. As temperature decreased, the saccharification rate increased, reaching its highest value of 75.04% at 40℃ (Figure 8B). The maximum saccharification rate reached 72.13% with 5 mL of enzyme (EST1051 and cellulase, 1:1, v/v). Fig. 8D showed the effect of different enzymatic hydrolysis time on the saccharification rate. The saccharification rate of WSB reached its highest value of 70.33% when the enzymatic hydrolysis time was at 10 hours. Table 1 showed the results of the orthogonal test. The primary factor affecting the saccharification rate of WSB was pH, followed by the secondary factors, enzymatic hydrolysis time, temperature, and addition amount. The optimal conditions for a peak saccharification rate of WSB were as follows: 40℃, 6 mL of enzyme, pH of 5.0, and 8 hours of enzymatic hydrolysis. The maximum saccharification rate of WSB was about 76.12%. So far, it has not been reported that the nature enzyme degrades water hyacinth with such high efficiency.

Materials and Methods

Strains, materials and chemicals

E. coli BL21 (DE3) and E. coli DH5α were purchased from TSINGKE Biological Technology (Guangzhou, China) and used as the expression host and cloning host, respectively. The pET-28a (+) was used for protein expression. T4 DNA Ligases, restriction endonucleases, DNA and protein marker were purchased from TaKaRa (Dalian, China). The DNA extraction kit and plasmid extraction kit were purchased from OMEGA (San Diego, CA, USA). Kanamycins (Kan), 5-Bromo-4-chloro-3-indolyl β-Dgalactopyranoside( X-Gal), IPTG and ρNP-C2 were bought from Sigma. Tryptone and yeast extract powder are from British Oxoid, and agar powder is purchased from Coolable. Electrophoretic agarose and Tris were purchased from PUBO Biological Technology (Beijing, China) and other chemical reagents were domestic analytical pure. Gene sequencing and primer synthesis were entrusted to Guangzhou TSINGKE Biological Technology.

Preparation of wheat straw biomass

Wheat straw was collected from rural areas in Heze, Shandong Province, China. Then the wheat straw is chopped, dried at 105 ℃, and finally ground into 0.1-1 mm powder. Take a certain amount of wheat straw biomass (WSB), add dilute NaOH (2%) in the ratio of 1:10 (g/ml) with soaking time 1 h at 40℃, then drain the dilute NaOH , wash WSB to neutralize the pH with distilled water [18].

Construction of the recombinant plasmid and transformation

The research about PCR amplification adopts pUC118- est1051 plasmid as template, est1051-F and est1051-R as primers respectively. The amplified products and vectors, pET-28a (+), are digested with EcoR Ⅰ and Xhol Ⅰ, then linked by T4 DNA Ligase. Finally, the constructed vector, pET28a-est1051, is transferred into E.coli BL21 (DE3). PCR primers for est1051 amplification were as follows: est1051-F, 5’-CCGGAATTCCCCGTTGCGGTGTCATTATACTGAC-3’; est1051-R, 5’-CCGCTCGAGGCTCCCGAAGAACCTATGAAACCAATTG-3’ (the EcoR Ⅰ and Xhol Ⅰ restriction sites are italicized). The PCR process is as follows: denaturation 2 minutes at 98 ℃, followed by 30 cycles of 10 seconds at 98 ℃, 5 seconds at 64 ℃, and 5 seconds at 72 ℃, then the final elongation step 8 minutes at 72 ℃. The expression vector pET-28a (+) are digested using EcoR Ⅰ and Xhol Ⅰ at 37 ℃ for 20 minutes and then ligated to the PCR products, which are treated with the same restriction endonuclease. The double-digested expression vector pET-28a (+) and the PCR products are ligated by TaKaRa T4 DNA Ligase at 16 ℃ for 14 h. This recombinant plasmid is transformed into E. coli BL21 (DE3) by heat shock method.

Expression, protein purification and electrophoresis

The protein was expressed by growing the E. coli BL21(DE3) cells in LB medium (50μg/mL concentration of Kan). For purification of EST1051 expressed by E. coli, the sediment is collected by centrifugation with 8000 rpm for 10 minutes at 4℃. Sediment was washed with sterile water twice and broken using an ultrasonicate with amplitude set at 30W for 15 minutes. Recombinant AXE EST1051 was purified using His-tag Protein Purification Kit (Novagen). Determination of the molecular weight of denatured protein by SDS-PAGE. The molecular weight of the expressed protein is determined based on the protein markers (TaKaRa) as the standards. According to the predicted molecular weight of protein and its relationship with different concentrations of polyacrylamide gel, separation, and concentration gels with concentration of 12% and 5% respectively are selected. The protein is stained with Coomassie brilliant blue G-250 for 10-12 h, and then decolorized with eluent.

AXE activity assay

AXE activity was measured using ρ-nitrophenol esters as the substrate [19]. The ester bond in ρ-nitrophenol esters can be decomposed by AXE. And the product is yellow p-nitropheno (ρNP). The absorption peak of ρNP was 405 nm, and there was a linear relationship between the absorption value and the content of ρNP. The standard curve is drawn using the ρNP concentration as the abscissa (X) axis, and the A405 value as the ordinate (Y) axis. Content of ρNP could be obtained through the standard curve by measuring the A405 value of the solution. One unit is defined as the amount of enzyme that release 1 μmol of ρNP per minute, under the conditions assayed [20].

Evaluation of Enzymatic Properties

AXE activity was determined using ρNP-C2 as the substrate, as mentioned previously. At the temperature of 40 ℃, the enzyme activity was measured in the range of pH 2-10. Took 190μL of 1μmol/L ρNP-C2 prepared with the 40mM Britton-Robinson (BR) buffer of different pH, added 10μL of purified enzyme solution, reacted for 20min, then took supernatant to determine the A405 value to obtain the optimal pH. The optimal temperature was investigated in the range from 4℃ to 80℃ at the optimal pH. 2 mL crude enzyme solution was prepared with BR buffer solution of different pH respectively, stored at 4℃ for 24 h, 10μL crude enzyme solution was taken, and the residual enzyme activity was determined under the optimum temperature and pH, the maximum enzyme activity was set as 100%. Put the enzyme solution into different temperature (4-80℃) for 24 h, measured the residual enzyme activity at the optimum temperature and pH according to the method described above.

The effects of various metal ions (Ni2+, Na+, K+, Mg2+, Zn2+, Fe2+, Mn2+, Li+, Ag+, Co2+, Cu2+) and chemicals (methanol, ethanol, isopropanol, DMSO, Triton X-100) on EST1051 activity were investigated by preincubating the enzyme for 20 minutes at an optimum temperature and pH. The enzyme activity without any reagent’s addition was set as 100%. KCl and NaCl were used to study the salt tolerance of the recombinant enzyme. The activity of the enzyme was determined in the optimal pH buffer with a salt solution of concentration range from 0mM to 2mM at the optimal temperature and pH. The enzyme with no added agent was used as a control.

The kinetic constants Km and Vmax of AXE were determined using ρNP-C2 as substrate. The Ρnp-C2 with different concentrations range from 0.0mg/mL to 5.0mg/mL are prepared with the buffer solution of optimum pH. Take 190μL ρNP-C2 solution with different concentration respectively, add 10μL 0.62mg/ml enzyme solution, react for 20 minutes under the optimal temperature, take out the reaction solution, then measure A405. The absorption value at 0.0mM was negative control, and the concentration of ρNP-C2 was determined. According to the substrate concentration [S] and the measured initial reaction rate V, the Linear Weaver Burk double reciprocal plot (formula: [ ] ( [ ]) max m V=V S K + S ) was made for 1/V, and the enzymatic kinetic parameters m K and max V of AXE were calculated respectively.

Enzymatic hydrolysis of wheat straw biomass

There was a linear relationship between the absorption value and the content of reducing sugar. The standard curve was drawn using the glucose concentration as the abscissa (X) axis, and the A570 value as the ordinate (Y) axis. Reducing sugar content could be obtained through the standard curve by measuring the A570 value of the solution. The optimal conditions were tested with WSB. The wheat straw contained high amounts of lignin, cellulose, and hemicellulose that were converted to a reducing sugar by cellulase and AXE.

First, single factor analysis was used to study degradation of the WSB by changing the pH, temperature, enzyme dosage, and enzymatic hydrolysis time. Then, an L9(34) orthogonal design (Table 2) was used to determine an optimal degradation combination. The reaction mixtures contained the WSB (0.2g), Britton-Robinson buffer (40mM), cellulase and EST1051 enzyme solution (v/v,1:1) in a 20-mL system at 200rpm. Enzymatic extraction of the WSB was determined using spectrophotometry. The supernatant was centrifuged to measure absorbance at 570nm. All reactions were performed in triplicate.

Nucleotide sequence accession number

This nucleotide sequence had declared the GenBank and obtained the registration number as MK111431.

Conclusion

In this study, we cloned a novel AXE gene, Est1051. Then the gene was successfully expressed in the prokaryotic system to explore its stability, enzymatic properties, the synergism with cellulase on degrading straw. It showed high activity in a wide pH range, good thermostability and excellent tolerance of organic solvents and salt. The recombinant enzyme was purified and characterized. In this experiment, the novel AXE was used to degrade and transform wheat straw directly damaging the plant cell wall. AXE directly converted wheat straw into glucose during the short test period. This study identified new AXE, enriched the source of AXE and made full use of AXE. Meanwhile, it provided a research basis for improving the utilization rate of cellulose-rich plants.

Author Contribution

XZ have done enzyme assay and written the manuscript. QY and WZ determined the enzymatic properties and tested extraction straw of the enzyme., protein purification and electrophoresis. MZ have done the optimal conditions for enzyme production. SD have completed the immobilization experiment. HL have revised the manuscript, conceived the study, and supervised the experiments. All authors have read and approved the manuscript.

Funding

This work was supported by Natural Science Foundation of China (31400680), Science and Technology Plan Project of Guangzhou (201802030009) , the Innovation and Strengthening School Project from Guangdong Pharmaceutical University (2016KTSCX067 and 2016SFKC_28), Science and Technology Plan Project of Guangdong Province (2017A010105011 and 2014A020208134), and Science and Technology Plan Project of Guangdong Province (2014A020212602) , Education Project of Guangdong Province (2013KJCX0107).

References

- Hea JC, Seung MP, Hak, RK, MoonSikYang, DaeHyukKim (2002) Cloning the gene encoding acetyl xylan esterase from Aspergillus ficuum and its expression in Pichia pastoris. Enzyme Microb Tech 31(4): 384-391.

- Hakulinen N, Tenkanen M, Rouvinen J (2000) Three-dimensional structure of the catalytic core of acetylxylan esterase from Trichoderma reesei: insights into the deacetylation mechanism. J Struct Biol 132(3): 180-190.

- Hakulinen N, Tenkanen M, Rouvinen J (1998) Crystallization and preliminary X-ray diffraction studies of the catalytic core of acetyl xylan esterase from Trichoderma reesei. Acta Crystallogr D 54(3): 430-432.

- Ding SJ, Cao J, Zhou R, Fei Zheng (2007) Molecular cloning and characterization of a modular acetyl xylan esterase from the edible straw mushroom Volvariellavolvacea. Fems Microbiol Lett 274(2): 304-310.

- Koseki T, Miwa Y, Akao T, OsamuAkita, KatsumiHashizume (2006) An Aspergillus oryzae acetyl xylan esterase: molecular cloning and characteristics of recombinant enzyme expressed in Pichia pastoris. J Biotechnol 121(3): 381-389.

- Huy ND, Thiyagarajan S, Kim DH, SeungMoonPark (2013) Cloning and characterization of a novel bifunctional acetyl xylan esterase with carbohydrate binding module from Phanerochaetechrysosporium. J BiosciBioeng 115(5): 507-513.

- Aiguo Y, Hao L (2010) Research on Issues of Resources and Environment. International Conference on E-education 586-588.

- Kirtay E (2009) The role of renewable energy sources in meeting turkey's electrical energy demand. p. 13-17.

- Miao X, Lin J, Bian F (2020) Utilization of discarded crop straw to produce cellulose nanofibrils and their assemblies. J BioresBiopro 5(1): 26-36.

- Huang C, Han L, Liu X, Ma L (2010) The rapid estimation of cellulose, hemicellulose, and lignin contents in rice straw by near infrared spectroscopy. Ene Sou Part ARecovUtili Environ Effe 33(2): 114-120.

- Prade RA (1996) Xylanases: from biology to biotechnology. Biotechnol Genet Eng Rev 13(1): 101-132.

- Ghysel F, Godin B, Flamin C, Delfosse P, Delcarte J, et al. (2010) Forages as sources of energy: comparison of three methods of production, with their consequences and opportunities. Fourrages (203): 163-173.

- Tamilvendan M, Rui L, Zhihua Z, GenZou (2017) Optimization of acetyl xylan esterase gene expression in Trichoderma reesei and its application to improve the saccharification efficiency on different biomasses. Proc Biochem 58:160-166.

- Shohreh A, Farzaneh J, Parvin H, Leila Ma'mani, Sajjad Gharaghani,et al. (2020) An efficient nano-biocatalyst for lignocellulosic biomass hydrolysis: Xylanase immobilization on organically modified biogenic mesoporous silica nanoparticles. Int J Biol Macromol 164:3462-3473.

- Coniglio RO, Gabriela V, Díaz MI, Fonseca ML (2020) Enzymatic hydrolysis of barley straw for biofuel industry using a novel strain of trametesvillosa from paranaense rainforest. Prep Biochem Biotechnol (2): 1-10.

- Bahiru T, Chandrajit B, Partha R (2020) Organosolv pretreatments of rice straw followed by microbial hydrolysis for efficient biofuel production. Renew Ener148:923-934.

- Cheeseman MT, Bates, PA, Crampton JM (2001) Preliminary characterisation of esterase and platelet-activating factor (PAF)-acetylhydrolase activities from cat flea (Ctenocephalides felis) salivary glands. Insect Biochem Mol Biol 31: 157-164.

- Wang Y, Spratling BM, ZoBell DR, R D Wiedmeier, T A McAllister (2004) Effect of alkali pretreatment of wheat straw on the efficacy of exogenous fibrolytic enzymes. J Anim Sci 82(1):198-208.

- Aogaichi T, Plaut GWE(1977) Assay of the esterase activity of thrombin, plasmin and trypsin with a chromogenic substrate p-nitrobenzyl p-toluenesulfonyl-l-arginine. ThrombHaemost 37(1):253-261.

- Janssen PH, Monk CR, Morgan HW (1994) A thermophilic, lipolytic Bacillus sp. and continuous assay of its p-nitrophenyl-palmitate esterase activity. Fems Microbiology Letters 120(1-2):195-200.