Forecasting the Composition of Catalysts Of Hydrogenization of Oil and Fat

Sattarov KK and Mazhidov KH*

Doctor of Technical Sciences, Russia

Submission: July 28, 2018; Published: August 03, 2018

*Corresponding author: Mazhidov KH, Doctor of Technical Sciences, Russia, Tel: 998905140640; Email: kafedra-03@mail.com

How to cite this article: Sattarov KK, Mazhidov KH. Forecasting the Composition of Catalysts Of Hydrogenization of Oil and Fat. Organic & Medicinal Chem IJ. 2018; 7(4): 555717. DOI: 10.19080/OMCIJ.2018.07.555717

Abstract

The technique of the theory of pattern recognition in predicting the chemical-technological characteristics of alloyed promoted nickel-copper-aluminum stationary catalysts was used. The most effective promoting metals are selected. An increase in the activity and other hydrogenating properties of the hydrogenation catalysts for fats and oils has been achieved.

Keywords:Alloy catalysts; Promoting metals; Methods for selecting promoters; The use of the theory of pattern recognition; Activity prediction; Chemical and technological characteristics

Introduction

Modern concepts of heterogeneous catalysis link the catalytic activity of solids with structure, chemical composition, energy of stabilization of the crystal field, acid-based surface properties, etc., which together constitute the theoretical basis for the selection of catalysts for reactions of a certain type or group of chemical transformations of the same type .The search for suitable catalysts to accelerate certain reactions based on current knowledge of the range of substances that are potential catalysts and general ideas about the mechanisms of their action is attributed to the tasks of predicting catalysts [1-3]. The theoretical direction cannot yet claim a successful prediction of catalysts, but quantum-mechanical concepts of heterogeneous catalysis play an important role in predicting catalysts using the methods of pattern recognition theory [4-6]. Mathematic-heuristic direction is the development of classical correlation methods and in its essence is a set of statistical computer methods of information processing, generalized by the theory of pattern recognition.

The solution of the recognition problem is based on the initial empirical material - the “training sample”.

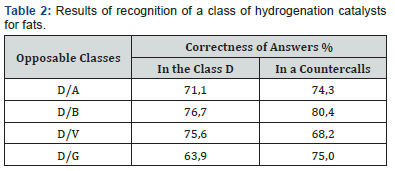

The simplest problem solved by the methods of the pattern recognition theory [7,8]. is the selection of a promoter or other modifying additive to a known catalyst. The initial information for the creation of the training sample was the literature and patent data on the composition and properties of heterogeneous catalysts for hydration reactions. The latter were subdivided into 5 classes in accordance with the VA Roiter classification [9]. The results of recognition of the class of catalysts for the hydrogenation of fats as a function of the counter class (Table 1) are listed in Table 2. It should be noted that if the catalysts of one class from catalysts of another class were less than 70%, they were considered included in the latter. Accordingly, recognition within 70-100% means an independent existence of the class. The analysis of classes carried out in [10] (Table 1). allowed us to state that all hydrogenation catalysts are practically suitable for the hydrogenation of fats, with the exception of typical catalysts for the hydrogenation of the acetylene bond [11]. For the prediction of effective promoters of alloyed nickel-aluminum catalysts for hydrogenation of fats, the methods of the pattern recognition theory [12].

were used. The solution of recognition problems is based on the initial experimental material - the “training sample”, each object of which xij (j = 1 ... M) is described by a system of signs (i = 1 ... N). Thus, the training sample can be represented by a matrix of dimension MxN, where M is the number of objects (in our case, catalysts), and N is the number of catalyst features:

Each matrix represents a specific array, a class of catalysts. In the algorithm “Leader” used, the training sample is divided into 2 arrays |х_ij | and |х ̅ ij |, that is, two classes of catalysts -A and А ̅. In each case, the selection of specific training sample objects and their number, as well as the division of the entire sample into two (in this case) array is carried out in advance, based on the task and on the basis of studying both literary and own experimental material. In our case, the data are indicative of the component (elemental) composition of the catalysts. And as the sample objects, catalysts of several hydrogenation classes are used (Table 1). As a recognition algorithm, a binary linear classifier of images, the so-called threshold logic element, was used. In this case, the affiliation of catalysts to one of the two arrays (images) - A or А ̅ - is determined by calculating the distances from the objects (individual catalysts) to the centers of alternative classes - standards A and А ̅, represented in the multidimensional Euclidean space of the characteristics describing these objects. We denote the volume of the training sample by the index M. Then the volume of the class A is equal to MA, and the volume of the class А ̅ is equal to MА ̅, that is:

The set of objects of classes A and А ̅ can be expressed in terms of the sums:

Then the coordinates of the centers of classes A and А ̅, that is, the coordinates of the standards А* and А ̅^*are equal to:

Distance between the object and the standard in the general case is calculated by the formula:

Comparing the pairwise distances from the object to the standards, determine the belonging of the given object (of the given catalyst) to one or another class (of two pairwise matched ones).

Obviously, if

The object belongs to class A.

Conversely, if

The object belongs to class A ̅.

The reliability of recognition (classification by two classes) is estimated by the proportion of correct estimates (classifications) in arrays A and A ̅.

Denote +i- the number of correct classifications of objects in classes A and A ̅, respectively. Then, taking into account the volumes of the classes MA and MA ̅, we find the fractions of the correct classifications of objects in these classes:

The average level of image recognition is half the sum of recognition levels in each alternative class:

If we now consider a new object that is not included in the training sample - object y (y1 ... yn) then, as in the previous cases, the new object y belongs to the class A - yi A, if the following condition is met:

In the opposite case, the object y belongs to the class A ̅ (yi ∈ A ̅).

A measure of the prospects of each of the objects is the distance to the “Leader” - a point in the multidimensional space of characteristics describing objects. We denote this distance as П = рх, л.

Conditions of object leadership:

As already noted, the distance from the object to the standard allows us to detect the similarity of the object with other catalysts of this class. To strengthen the definition of an object’s belonging to a particular class, the conditions for distinguishing this object from catalysts of another class are also introduced.

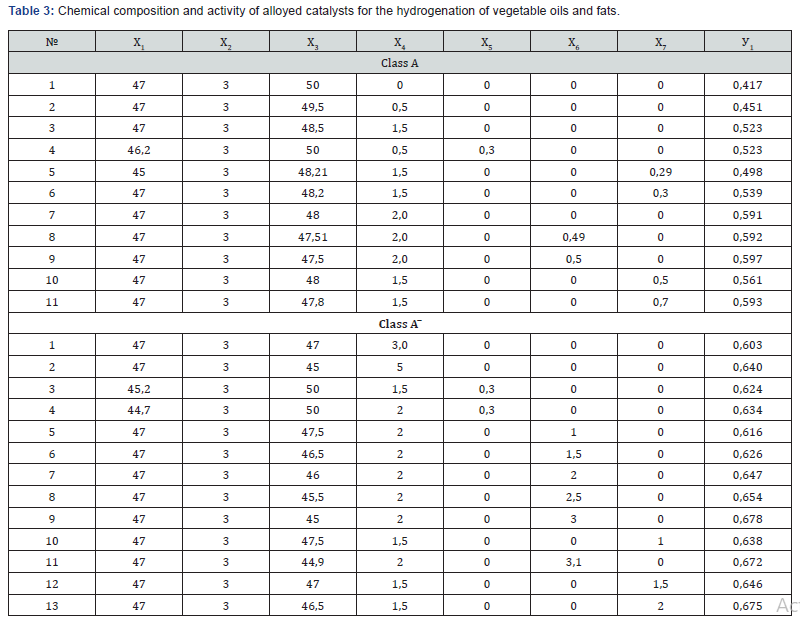

These conditions consist in the requirement of proximity to a non-reference standard of this class. The distance of the leader from the standards of the opposing classes should be minimum and maximum, respectively, as expressed by the above formulas. Obviously, the prospectivity of this object is the greater, the smaller the distance between the object and the leader П = рх, л. According to the data of [13]. the predictive ability of the technique for solving the problems of selecting catalysts is 75- 100%. In this paper, the version of the “Leader-FS” program was used, which has a blurred classification block. This method was carried out as follows: At the first stage of the work, we used the pattern recognition technique to predict the qualitative and quantitative composition of alloyed nickel-aluminum and copper catalysts. For the forecasting, the data obtained in our experiments, as well as the literature and patent data [1]. were used. Experimental information is presented in Table 3. In which the indices y1 denote the activity of the catalyst of the given composition, and the indices x1-x7 the component composition of the catalyst (alloy) in weight. percentages: x1-nickel, x2- copper, x3-aluminum, x4-germanium, x5-rhodium, x6-rhenium, x7-ruthenium. The entire array of catalysts by activity (y) was divided into two classes. Class A-11 objects, class A ̅-13 objects. The conditions for the belonging of catalysts to this or that class:

When processing the data in Table 3, the chemical composition was normalized. Condition of normalization of the characteristic:

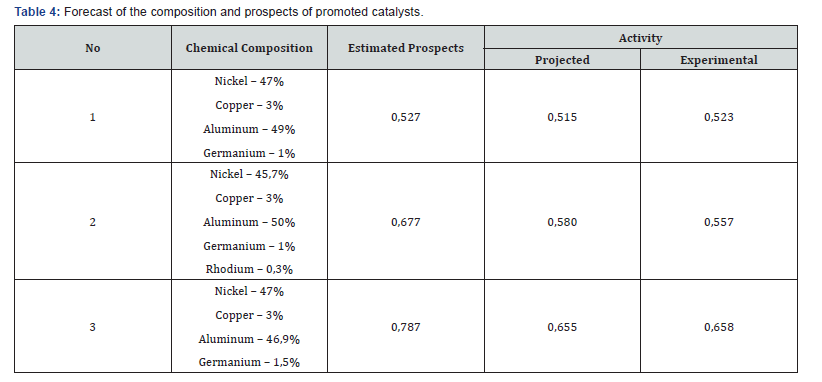

where x*i is a normalized trait; xi is the given (i-th) sign in the initial scale of measurements, xmax is the maximum value of the given characteristic in the analyzed series. As a result of solving pattern recognition problems, the recognition of highly active catalysts (class A ̅) was 100%, and for anticlass A - 79% (Figure 1). Further, as a result of the evaluation of the perspectivity of the learning sample objects, a correlation was obtained between the activity and the calcula ted catalyst prospects. Linear correlation is shown in Figure 2. In this graph, three catalysts (alloys) were identified, for which the proposed chemical composition was compared in Table 4 and the data presented generally indicate that the activity of the catalyst increases significantly when the alloy is promoted by germanium, as well as germanium + rhodium and germanium + ruthenium systems. Obviously, the last two catalysts of Table 4 are the most “promising” ones. But the fulfilled forecast is based only on the activity of the catalysts.

Conclusion

The probable efficiency of the use of selected promoters in the composition of nickel-copper-aluminum alloy stationary catalysts for the improvement of the chemical-technological characteristics of the catalysts studied was previously identified based on the use of elements of the theory of pattern recognition. The calculated promising calculated (predicted) activity and experimental activity.

References

- Majidov KKH (1972) Investigation of the continuous hydrogenation of cottonseed oil on alloyed nickel-copper catalysts for the purpose of obtaining salomass for food purposes: Abstract of the dissertation. Dis Cand Tech Science-L p. 21.

- Temkin MI, Konyukhov VY, Kulkova NV (1984) Kinetics of heterogeneous catalytic hydrogenation of liquids. Kinetics and catalysis 15(5): 1257-1259.

- Sokolsky DV (1972) Hydrogenation in solutions. Alma-Ata: Science pp. 310.

- Roberts M, Mackie C (1981) Chemistry of the metal-gas interface. M: The world pp. 539.

- Ioffe II, Reshetov VA, Dobrotvorsky AM (1985) Heterogeneous catalysis. L: Chemistry pp. 224.

- Ioffe II, Dobrotvorsky AM, Belozerskikh VA (1983) Prediction and analysis of the mechanism of action of heterogeneous catalysts by means of computers by the methods of pattern recognition. Uspekhi Khimii 3: 402-425.

- Amirova ZK, Masagutov RM, Morozov BF (1980) Spivak SI Analysis of the problem of selection of catalysts using the methods of pattern recognition. Kinetics and catalysis 21(5): 1174-1177.

- Ioffe II, Reshetov VA, Dobrotvorsky AM (1977) Calculation methods and forecasting of heterogeneous catalysts. Chemistry pp. 208.

- (1968-1977) Catalytic properties of substance Handbook. VA Reuter Kyiv: Naukova Dumka p. 60.

- Amirova ZK, Masagutov RM (1986) Selection of promising catalysts for the synthesis of PMDA by the pattern recognition method. Studies in the synthesis of anhydrides of polycarboxylic acids M CNIITE Neftekhim pp. 113-120.

- Krupenia NG, Bizhanov FB, Sokolsky DV (1984) Influence of hydrogenation conditions on the fatty acid composition of Salomass Fat-and-oil industry 11: 18-19.

- Majidov KKH (1987) Research and improvement of the technology of hydrogenation of cottonseed oil on modified alloy stationary catalysts. Dis Doc-techn sciences p. 48.

- Amirova ZK (1980) Selection of catalysts for transformations of organic compounds using the methods of pattern recognition: Author’s abstract. Dis Candidate of Chemistry, Bashkir Branch of the USSR Academy of Sciences p. 20.