Acrylic-Silicone Pressure-Sensitive Adhesives

Adrian Krzysztof Antosik* and Zbigniew Czech

Institute of Organic Chemical Technology, West Pomeranian University of Technology Szczecin, Poland

Submission: December 08, 2017; Published: December 22, 2017

*Corresponding author: Adrian Krzysztof Antosik, Institute of Organic Chemical Technology, West Pomeranian University of Technology Szczecin, ul. Pulaskiego 10, 70-322 Szczecin, Poland, Email: adriankrzysztofantosik@gmail.com

How to cite this article: Adrian K A, Zbigniew C. Acrylic-Silicone Pressure-Sensitive Adhesives. Organic & Medicinal Chem IJ. 2017; 4(5): 555648.DOI10.19080/OMCIJ.2018.05.555648

Abstract

Novel acrylic-silicone pressure-sensitive adhesives self-adhesives tapes have been reported. For tape preparation acrylic and silicone resin solvents in toluene have been used. Obtained tape were subjected physicochemical test (adhesion, cohesion, tack) in order to determine their properties. Using UV-curable acrylic resin in composition allows the UV-cross linking technology in non-UV-reactive silicone pressure-sensitive adhesives. Silicone-acrylate compositions have shown to improve the cohesive properties at elevated temperatures (over 72 h), while a slight reduction in adhesion and tack. This suggests that the relatively cheaper than silicone adhesives received the compositions may in the future replace the acrylate adhesives.

Keywords: Silicone pressure-sensitive adhesives; Acrylic pressure-sensitive adhesives; Acrylic-silicone; UV-curable; Adhesion

Introduction

From mechanically point of view, pressure-sensitive adhesives (PSA) can be describe as a soft, sticky viscoelastic material, which in a solvent free state remains permanently tacky at room temperature. Under light pressure they adheres to a substrate and they can be removed cleanly, on demand, without leaving residues on the substrate. PSA should have cohesive strength that is much higher than its adhesion strength to the substrate to exhibit this property [1-3]. Since silicone pressure- sensitive adhesives (SiPSA) commercial introduction in the 1960s they have found uses in industrial operations; in 2000, there has been continuing interest in it of new uses for silicone PSAs, especially in applications such as medical and industrial tapes [1-5].

In compared to organic PSAs SiPSAs are superior due to their unique properties such as flexibility, chemical resistance and outstanding weathering resistance low intermolecular interactions, low surface tension, excellent thermal stability and high UV transparency. Silicone pressure-sensitive adhesives exhibit hydrophobic and inert (for the live organism properties), they can be utilized over a wide range of temperatures (-40 to +300°C). They can be cross linking thermally between 120 and 150°C using organic peroxides [6-9]. Acrylic polymers are the most commonly used self-adhesives, having replaced compounded natural or synthetic resin. Acrylic offer oxidative stability and resistance to UV radiation are inherently tacky and can be adapted to a variety of uses by copolymerizing two or more monomers, including non acrylates such as vinyl acetate, N-vinyl pyrolidone, or N-vinyl caprolactame. The composition of acrylic polymers that are inherently pressure-sensitive is a combination in the polymer chain of soft (low glass transition temperature Tg), hard (high glass transition temperature Tg) and functional monomers.

Normally acrylic PSAs contains typical hard and soft monomers, as well as the types of functionality that can be incorporated into the polymer chain [5,10-12]. Acrylic PSA retain the most important proportions for a pressure- sensitive adhesive from the point of view of the industry, such as high tackiness, cohesion and high adhesion; UV, solvent and temperature stability. In compared to SiPSA acrylic PSA exhibit lower adhesion to non-polar materials is caused by the polar chemistry of this self-adhesive materials [11-14]. In this paper commercial acrylic and silicones adhesives will be used as a component to obtained acrylic-silicone composition using to prepared self-adhesives tape based on acrylic-silicone adhesives. In the available literature there are no reports about tape based on acrylic-silicone PSA composition. This new composition is pressure-sensitive adhesives exhibit good useful properties. They can find application in variant of industry where should showed good multiple tack.

Materials and Methods

Materials

In work commercial acrylic and silicone adhesive was used (acronym: A 204 UV and PSA 590), which was product of respectively of respectively BASF (Germany) and Dow Corning (USA). Dichlorobenzoyl peroxide (DClBPO) was used as a cross linking agent. Peroxide was product of Peroxid-Chemie (Germany).

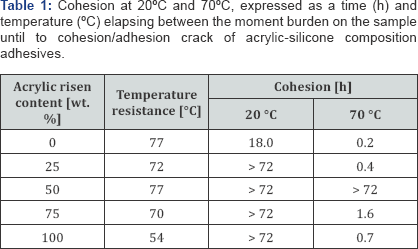

Preparation of tape based on acrylic-silicone pressure- sensitive adhesives: Silicone pressure-sensitive adhesive was mixed with crosslinking agent to obtain homogeneous composition containing 50 wt. % polymer (1.5 wt. % on a base of polymer content 2.4-dichlorobenzoyl peroxide (DClBPO)). Acrylic rise was mixed with toluene to obtain 50 wt. % polymer compositions. Then, the resulting mixture was mixed to obtain a homogeneous mixture containing 25 wt. % silicone adhesive, 25 wt. % acrylic adhesive and 50 wt. % solvent (toluene). Subsequently, composition was coated with coat speed of 5 cm/s on polyester film (36 μm), and dried for 10 min at 110°C in drying canal. After daring adhesives films was UV-cross linking (wave-length range between 220 and 280 nm - according to manufacturer's recommendations). Thus obtained adhesive film was protected with polyester film (50 μm). Obtained tapes were used for further tests, i.e. adhesion, tack and cohesion measured (Table 1).

Methods

Peel adhesion, tack, cohesion of silicone pressure-sensitive adhesives of PSA was measured using Zwick-Roell Z1 machine (Germany) and machine designed at the Laboratory for Adhesives and Self-Adhesive Materials of the West Pomeranian University of Technology Szczecin according to international standard Association des Fabricants Europeens de Rubans Auto-Adhesifs and Federation Internationale des Fabricants et Transformateurs d'adhesifs et thermocollants sur papiers et autres support respectively AFERA 4015, AFERA 4001 and FINAT - FTM 8 [9,14-16]. The cohesion was tested as expressed time in constant (at 20°C, 70°C) and as expressed temperature (°C) elapsing between the moment burden on the sample until to cohesion/adhesion crack.

Results and discussion

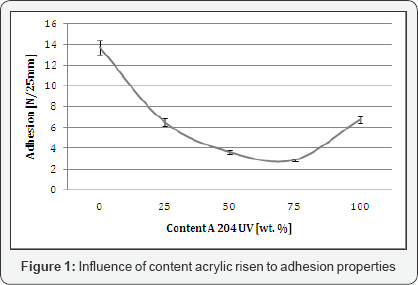

The highest adhesion demonstrated adhesives cross-linked pure silicone compositions. In most cases, adding acrylic pressure-sensitive adhesives contents decreased the value of adhesion composition (Figure 1). For pure composition (acrylic and silicone) has improved adhesion with highest value compared to mixed compositions. All acrylic-silicone compositions showed lowest adhesion then 10 N/25mm. For all compositions increasing adding acrylic pressure-sensitive adhesives contents decreased the value of tack (Figure 2). Crosslinked acrylic pressure-sensitive adhesives associated with very low tack (low then 2 N/25mm) by this feature the addition of A-PSA decreases tack [17].

Conclusion

Novel acrylic-silicone pressure-sensitive adhesives selfadhesives tapes have been obtained. For tape preparation acrylic and silicone resin solvents in toluene have been used. New tapes were subjected physicochemical test (adhesion, cohesion, tack) in order to determine their properties. Using UV-curable acrylic resin in composition allows the UV-cross linking technology in non-UV-reactive silicone pressure-sensitive adhesives. All acrylic-silicone compositions showed lowest adhesion then 10 N/25mm and tack then 8 N/2 5mm respectively lower 7 and 6 N/25mm. It is generally accepted that one-sided adhesive tape must meet the basic properties (adhesion > 10N/25mm; tack > 8 N/25mm; cohesion > 72 hours) [3] lowest properties usualy determinet use compositions to repeatedly self-adhesive materials. Composition with 50 wt.% acrylic risen exhibit best usefull properties.

References

- Lin SB, Durfee LD, Ekeland RA, McVie J, Schalau GK (2007) Recent advances in silicone pressure-sensitive adhesives. J Adhe Scien Tech 21: 605-623.

- Khan I, Poh BT (2011) Natural rubber-based pressure-sensitive adhesives: a review. J Polym Enviro 19: 793-811.

- Antosik AK, Bednarczyk P, Czech Z (2015) Jednostronnie klej^ce tasmy na bazie samoprzylepnych klejow silikonowych-dobor najlepszej kompozycji. Chemik 69: 95-97.

- Anderson GL, Stanley SD, Young GL, Brown RA, Evans KB, et al. (2010) The effects of silicone contamination on bond performance of various bond systems. J Adhe 86: 1159-1177.

- Czech Z, Kurzawa R (2007) Acrylic pressure-sensitive adhesive for transdermal drug delivery systems. J App Polym Scien 106: 443-446.

- Tolia G, Li SK (2012) Study of drug release and tablet characteristics of silicone adhesive matrix tablets. Euro J Pharm Biopharm 82(3): 518525.

- Mecham S, Sentman A, Sambasivam M (2010) Amphiphilic silicone copolymers for pressure sensitive adhesive applications. J App Polym Scien 116: 3265-3270.

- Sun F, Hu Y, Du HG (2012) Synthesis and characterization of MQ silicone resins. J App Polym Scien 125: 3532-3536.

- Antosik AK, Raganska P, Czech Z (2014) Termiczne sieciowanie samoprzylepnych klejow silikonowych nadtelenkami organicznymi. Polimery 59: 792-797.

- Peykova Y, Lebedeva OV, Diethert A, Muller BP, Willenbacher N (2012) Adhesive properties of acrylate copolymers: Effect of the nature of the substrate and copolymer functionality. Inter J Adhe 34: 107-116.

- Czech Z, Butwin A (2009) Poliakrylanowe kleje samoprzylepne sieciowane dualnie. Wiad Chem 6: 270-84.

- Qie L, Dube MA (2010) The influence of butyl acrylate/methyl methacrylate/2-hydroxy ethyl methacrylate/acrylic latex properties on pressure sensitive adhesive performance. Inter J Adhe 30(7): 65464.

- Gurney RS, Morse A, Siband E, Dupin D, Armes SP, et al. (2015) Mechanical properties of a waterborne pressure-sensitive adhesives with a percolating poly(acrylic acid)-based diblock copolymer network: Effect of pH. J Colloid Interface Sci 448: 8-16.

- Kowalski A, Czech Z (2015) The effects of substrate surface properties on tack performance of acrylic pressure-sensitive adhesives (PSAs). Inter J Adhe Adhe 60: 9-15.

- Antosik AK, Czech Z (2015) Wplyw ilosci barwnika na fizyczne wiasciwosci silikonowych klejow samoprzylepnych. Przem Chem 94: 41-42.

- Wilpiszewska K, Czech Z (2014) Citric acid modified potato starch films containing microcrystalline cellulose reinforcement-properties and application. Starch 66: 660-667.

- Antosik AK, Bednarczyk P, Czech Z (2016) Wplyw nanocz^stek kaolinu na fizyczne wiasciwosci silikonowych klejow samoprzylepnych. Przem Chem 95:1000-1003.