Community and Workers’ Health Risk Assessment Immediately after a Major Incident in an Industrial Plant and during the Subsequent Clean-up Phase

Peter J Boogaard1*, Peter M J Bos2 and Jan H Urbanus3

1Wageningen University & Research, Division of Toxicology, PO Box 8000, 6700EA Wageningen, The Netherlands

2National Institute for Public Health and the Environment (RIVM), Bilthoven, The Netherlands

3Shell Health, Belgian Shell NV, Brussels, Belgium

Submission:December 2, 2024;Published:December 10, 2024

*Corresponding author:Peter J Boogaard, Wageningen University & Research, Division of Toxicology, PO Box 8000, 6700EA Wageningen, The Netherlands Email: peter.boogaard@wur.nl

How to cite this article: Peter J B, Peter M J B, Jan H U. Community and Workers’ Health Risk Assessment Immediately after a Major Incident in an Industrial Plant and during the Subsequent Clean-up Phase. Open Acc J of Toxicol. 2024; 6(2):555683. DOI: 10.19080/OAJT.2024.06.555683.

Summary

In a chemical installation that was designed to produce monomers for the plastics industry an explosion occurred which was followed by a fire. The installation contained a process catalyst in the form of pellets consisting of several metal compounds classified for health and environmental effects, including hexavalent chromium. After the explosion and fire, catalyst material was found up to 300 m from the reactor, but within the perimeter of the chemical site to which the installation belonged. Smoke and ashes from the fire were transported to communities in the neighborhood by the wind. There was concern about potential environmental health impacts since catalyst-containing debris resulting from the explosion might also have been transported off site by the wind. Therefore, the concentrations of potential contaminants were measured in the environment of the neighboring communities for a period of two weeks. For the clean-up of the site and the demolition of the damaged installation a specific strategy was developed to assess the level of contamination, required personal protective equipment and clean-up procedures. Specific sampling strategies were developed to assess potential contamination of the remains of the plant, the surrounding roads and nearby installations. In the months following the incident, all individuals entering the contaminated area and all individuals involved in the clean-up were offered biological monitoring to check whether the personal protection measures taken were sufficient. In addition, immediately after the incident a mental health support program was set up for the staff of the affected site with the assistance of professional counsellors retained on call-off contract.

Results of the measurements in the potentially exposed communities showed that the concentrations of volatile organic compounds were below the level of detection in the hours following the incident. Due to the favorable weather conditions, only transient increases in the concentrations of Cr, Cu, Ba and Zn above the normal background level were observed in surface swipe samples as well in some grass samples collected in the communities; the concentrations of Cr(VI) were not increased at any place or any point in time. Analytical results from the industrial site indicated that levels in air were generally low to very low, indicating that deposited dust was not being resuspended. Surface contamination, as measured by targeted wipe sampling and assessed against adopted guideline values, on the other hand was detected over the entire 10-month period as clean-up and demolition progressed and proved a valuable risk management tool. Biological monitoring in the form of urine analysis in over 400 individuals indicated no exceedance of the biological exposure limit for chromium, the only metal with a biological exposure limit. Median values before and after potential exposure differed only very slightly for all tested metals, confirming the general efficacy of personal protective procedures. The experience led to a series of learnings which included fixation measures to prevent further spread of deposited contamination, clear demarcation of affected areas, controlled entrance under personal protective equipment, testing of clean-up effectiveness via wipe sampling, availability and acceptance of air, surface, and biological monitoring of contaminant levels, and rapid derivation of health reference values where these did not exist.

Overall conclusion Whilst major industrial incidents are fortunately rare in modern companies, preparedness for response, partnerships with authorities, and availability of scientific resources are crucial to understand and manage their health and environmental impact, as well as the levels of anxiety caused. The willingness to extract and share learnings further supports the continuous improvement of industrial risk management.

Keywords:Catalyst; Copper; Chromium; Human Biomonitoring; Air Monitoring; Wipe Sampling; Soil Sampling; Vegetation Sampling; Community Health; Occupational Health; Health Risk Assessment; Industrial Incident

Abbreviations:VOCs: Volatile Organic Chemicals, TEQ: Toxic Equivalents, TEF: Toxic Equivalent Factor, EAP: Employee Assistance Program, DOE: Department of Energy

Introduction

This paper describes the health risk management actions following a major incident in a chemical manufacturing plant and the subsequent follow-up to assess and control exposures to the hazardous substances potentially released. The chemical installation produces monomer building blocks for plastics in a process that applies a catalyst that consists of copper oxide (< 50%; CAS RN 1317-38-0), chromium trioxide (< 5%; CAS RN 1333-82-0) and barium chromate (< 10%; CAS RN 10294-40- 3) on a ceramic support consisting mainly of silicon dioxide. The incident occurred during a routine maintenance stop of the installation during which the catalyst was exchanged. According to standard procedure, spent catalyst had been removed from the reactor and fresh catalyst loaded after which the new catalyst was slowly heated up using warm ethyl benzene. Unexpectedly, an exothermic reaction occurred which led to an explosion of the ethyl benzene followed by a heavy, very hot fire. Fresh catalyst and debris from the explosion were released into the air. Following the explosion and fire, the initial health and environmental concerns for emergency response workers and surrounding local communities were focused on potential release of the process chemicals, including ethylbenzene. The nature of the release, however, suggested that most of those chemicals would have been combusted in the fire, leaving as the main issue exposure to any hazardous combustion product and catalyst debris.

As there was little wind at the time of the incident, the plume rose almost straight up, passed the inversion layer and was subsequently horizontally dispersed over a distance of several kilometers. After several hours the fire was put out. In the hours following the incident, reports came in of deposition of small, granular debris and ashes in neighboring communities. At the time of the explosion there were two workers present at the facility. As a precautionary measure they were hospitalized for observation. Both were released the following day and biological monitoring results (vide infra) showed that they had not been exposed to the process chemicals to any measurable extent. As it was realized that the severity of the incident, with explosion and fire, might trigger anxiety in workers, a mental support programmer was set up that was available to all individuals with concerns. Based on the differences in situation and time scale, the approach for health risk assessment and management were tailored to the needs for both the industrial site where the explosion occurred and for the surrounding communities. The industrial site covers a large area and visual inspection indicated that the catalyst pellets were spread around the site of the explosion over a distance of up to about 300 m but well within the fenced perimeter of the site. The industrial site is located next to a broad river and the communities downwind from the explosion were towards the North, at the other side of the river, at least 2.5 km away from the explosion site.

In contrast to the industrial site, the potential contamination of the communities was not directly visible. Nevertheless, immediately following the incident, the collection of environmental samples in the surrounding communities was started by public health authorities and samples were collected over a period of two weeks [1]. For the industrial site, the presence of several hazardous components in the catalyst triggered a precautionary protection programmer, with isolation of the affected plant area, restricted access of this area – which could be entered only with respiratory protective equipment and disposable coveralls -, setting up of a decontamination area, a bio-monitoring programmer and a program of environmental measurements directed at the hazardous catalyst components. It was anticipated that the inhalation of deposited (catalyst) dust re-suspended by wind would be the primary route of exposure, with a secondary concern related to direct skin contact with contaminated surfaces. Inhalation might occur due to aerosolized dust both from dust formed during the explosion and from dust resulting from crushing catalyst pellets during clean up. Apart from dermal exposure resulting from contact with contaminated surface, dermal exposure might also occur from contact with airborne dust. Exposure to volatile organic chemicals was deemed very limited as it was expected that the volatile compounds released with the explosion would almost instantly have been burned and that any remaining material would have readily evaporated and have been dissipated into the air.

A strategy was developed to determine the extent of the contamination on the site and to minimize exposure of personnel working in the contaminated areas. In view of the heavy reliance on personal protective equipment, biological monitoring of the potential contaminants was initiated (baseline samples at the beginning of the shift of the first working day and end-of-shift samples) for all workers, regardless of affiliation, who might have been exposed during and immediately following the incident. This programmer comprised first responders as well as incident investigators, operators and contractors involved in the clean-up of the site as well as individuals that had concerns about their exposure even if they had not been present in any potentially contaminated area. This report describes the approach followed, the results of the investigative measurements and subsequent health risk assessments immediately following the incident as well as the approach and results regarding exposure control, the validation of its efficacy during the clean-up phase, the mental support programmer and the lessons learnt.

Methods and Materials

Sampling strategy and chemical analyses Local communities

The health risk assessment for the local communities was led by the National Institute for Public Health and the Environment (RIVM) that coordinated measurements and conducted, in cooperation with local first responders such as police and municipal health services, the sampling and chemical analyses to inform the local authorities [1]. The number and type of locations are listed in (Table 1).

Air samples: In the hours immediately after the incident, fire brigades collected air samples in either Tedlar® bags or 6-litre stainless steel canisters at several locations in the local communities and at the entrance of the chemical site for analysis of volatile organic chemicals (VOCs). The Tedlar® bags were filled in a few seconds with a vacuum tube (grab sample) whereas the canisters were filled over a time span up to 2 hours allowing to obtain a time-weighted average airborne concentration. The air samples were collected in areas with, according to sensory observations (smell, sight) potentially the highest concentrations. VOCs in the collected samples were determined in a mobile laboratory by GC-MS according to the Compendium Method TO- 15; “Determination of Volatile Organic Compounds (VOCs) In Air Collected in Specially Prepared Canisters and Analyzed by Gas Chromatography/Mass Spectrometry (GC/MS)” by connecting the Tedlar bags or the canisters immediately to the GC-MS. The GC-MS was calibrated with TO-15 standard which comprises 65 frequently occurring VOCs.

Airborne dust samples: On the day of the incident no airborne dust samples were taken as there were no indications that there was any dust or smoke, but samples were taken 2 and 12 days after the incident to check whether metals might have been deposited and subsequently aerosolized. For the sampling a small filter device equipped with a quartz filter was applied. Air flow was set at either 2.3 m3/h or 6 m3/h for collection of PM10 and PM2.5 or total dust, respectively. The total amount of dust was determined gravimetrically (limit of detection ~ 30 μg/m3 and 1 μg/m3 for sampling time of 60 min and 24 h, respectively).

Surface swipe samples: On the day of the incident itself, and 2 and 12 days later, surface swipe samples were taken at various locations by collecting particles with tweezers from flat, horizontal surfaces with a surface area of 0.05 to 0.5 m2. The collected particles are deposited on wet cotton swabs and stored in plastic Petri-dishes. At each sample location at least two samples are taken.

Soil and grass samples: on the day of the incident itself, and 2 days later, soil and grass samples were taken at various locations. Twenty grass samples are randomly taken (sufficiently high above the ground to avoid contamination with soil) from an area of 5 x 5 m of the sample location and put together in a plastic bag.

Metals analysis: The dust, surface swipe, soil and grass samples were initially qualitatively analyzed for metals by XRFanalysis using a XEPOS analyzer. The concentrations of metals in the samples were later quantified by ICP-MS. For ICP-MS analyses, dust, surface swipe and grass samples underwent digestion with nitric acid or aqua regia and were subsequently analyzed for metals. For chromium analyses, the samples were dissolved in an aqueous solution of sodium hydroxide (2%) and sodium carbonate (3%), filtered and acidified with diluted hydrochloric acid and subsequently Cr(III) and Cr(VI) were determined by ICPMS.

PAH analysis: To determine PAH in the dust and surface swipe samples, part of the sample was extracted using a microwave assisted solvent extraction system with 40 ml acetone in a closed tube at 115˚C for 10 min. To determine PAH in grass samples, an aliquot of approximately 5 g was extracted twice with 20 ml of acetone by mechanical shaking for 30 min. For the PAH analyses, an aliquot of the acetone extract was analyzed by HPLC with fluorescence detection and quantified against a certified standard solution of PAH.

Dioxins analysis: To determine dioxin congeners, dust, surface swipe and grass samples were extracted with toluene. The extract was subsequently treated with active carbon and redissolved in toluene. Aliquots were analyzed by high resolution GCMS and quantified by isotope dilution using an external standard and single-point calibration. The 17 congeners were expressed as toxic equivalents (TEQ) based on the toxic equivalent factor (TEF) for each of the congeners.

Industrial site: At the industrial site the main strategy was to reduce the potential risk of exposure to hazardous substances following a precautionary approach.

Planning and strategy: Immediately following the incident, the site was visually inspected and, based on observations, a large section of the site that was situated immediately around the plant where the explosion took place, was closed off.

Fixation catalyst debris: The first few days following the incident the weather was rainy which prevented aerosolizing of any catalyst dust. As dry and windy weather was subsequently expected, there was a risk that catalyst dust and debris would dry and be aerolised by the wind and spread around. To prevent this, paper cellulose was sprayed onto the contaminated areas (assessed as being contaminated by visual inspection) to fix catalyst dust and debris. This was done by special machines that could sprayed the paper cellulose over a maximum distance of 75 m. The spraying was done from the roads around the contaminated area and allowed to fix the catalyst material on a large proportion of the presumably contaminated areas. However, the catalyst materials in the center of the exploded plant were initially out of reach and could only be fixed with paper cellulose after some of the outer areas of the contaminated site had been cleaned up.

Personal protective equipment and decontamination procedures: Immediately following the incident for all personnel that needed to enter the contaminated area to safeguard certain parts of the plant personal protective equipment was carefully chosen by the industrial hygienists. Since both inhalation and dermal exposure was expected, both respiratory and dermal protection were selected: a full-face mask equipped with an A2P3 filter, Tychem F disposable overalls, rubber boots and aliphatic gloves. To prevent contamination of both personnel during the removal of the protective equipment and of other parts of the site by spreading dust, a decontamination procedure was set up. This consisted initially of hosing off the persons leaving the contaminated area with water until special decontamination units were placed at the entrance/leaving sites of the contaminated area.

Environmental sampling: The initial environmental measurements of catalyst dust components in air and on surfaces were primarily directed at delineating the affected area and setting the worker protection requirements; in the following stages the measurements (mainly surface contamination) were used to assess the level of contamination of specific plant areas and equipment which were then cleaned, followed by further monitoring until considered clean enough to be released for access, repair and/or demolition. The nature of this programmer required rapid turnaround of analytical results, preferably overnight, in order to minimize waiting time of dedicated personnel and equipment. Part of the demolition was done in an area still containing catalyst debris. A special cleaning location was built to clean the scrap waste coming out of the uncleaned area. Wipe samples were collected to assess the level of contamination of scrap waste after cleaning. Frequent visual inspection as well as 6 to 10 surface contamination measurements were performed of the cleaned scrap waste until clean enough to be released to remove from site.

Surface monitoring: Surface monitoring was undertaken to

determine the level of contamination and the need for clean-up.

Surfaces that presented themselves were:

i. Smooth: metal plant structures etc. (ASTM D 6966)

ii. Rough: in particular the plant roads that had been paved

with a porous asphalt meant to facilitate rainwater run-off (ASTM

D7144 and D5438)

iii. Grass: vacuuming method did not work, hence resorted

to scrape sampling.

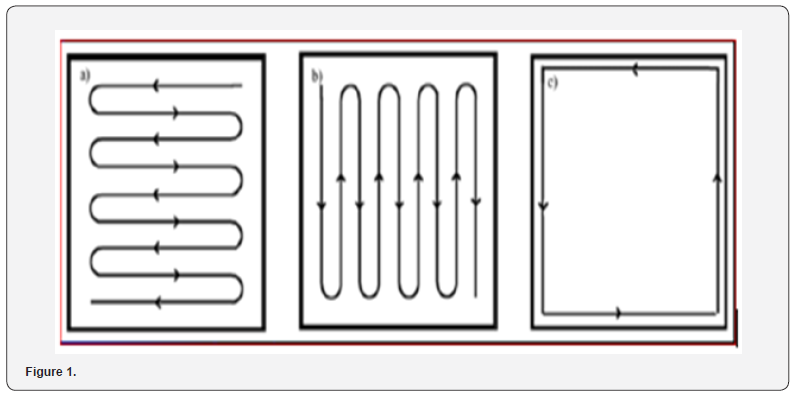

Existing recommendations for standardized surface monitoring typically require the use of a wipe sample medium such as a filter which is manually passed over the surface within a mold of 100 cm2 following a standardized pattern and applying constant pressure (e.g., IH75190), see figure xx taken from reference 6 (Figure 1). This technique is suitable for relatively smooth surfaces. The affected plant area however also had access streets, paved with a porous asphalt grade and the resuspension of dust from the pores by vehicle wheels was considered a potential source of air emission of particular concern; this porous surface could not reliably be sampled with the wipe sampling technique, hence an approach using a vacuum cleaner was implemented for those surfaces where wipes were not technically feasible. The same recommendations for standardized surface monitoring with the vacuum cleaner was applied following the same standardized pattern. This was described in an internal method description of the contracted, accredited laboratory (T005 sampling method for metals on surfaces). For the analysis of barium, copper and total chromium, the analytical procedure was based on ISO/DIS 30011 and consisted of digestion in nitric acid, followed by ICP-MS. Chromium (VI) analysis followed a procedure equivalent to NIOSH 7600, involving digestion in an alkaline solution, acidification and complexing with diphenyl carbazide into a pink compound quantified by spectrophotometry.

Surface water monitoring and treatment: Surface contamination was also transported to surface water by fire extinguishing water, rain and water used to clean the contaminated surfaces. To measure contamination in the collected surface water, a standard analytical procedure was followed (results not shown). Collected surface water was filtered in a dedicated unit, designed for hydrocarbons and metals, prior to discharge into the nearby river.

Air monitoring: A standard approach was followed to collect static samples of inhalable dust in air, using a calibrated pump at a flow rate of 2,0 liter/min using IOM filter heads with PVC filters for Cr(VI) and methylcellulose filters for other metals. The analysis of the metals was by ICP-MS (ISO30011) and digestion (NENISO 15202-2 Annex G), the analysis on chromium VI is done by colorimetry (equivalent to NIOSH 7600). Results were compared against applicable occupational exposure limits for 8-hour time weighted average exposures. Detection limits (per filter) were barium (0,2 μg), copper (0,2 μg), total chromium (0,1 μg), zinc (1,0 μg) and chromium VI (0,1 μg).

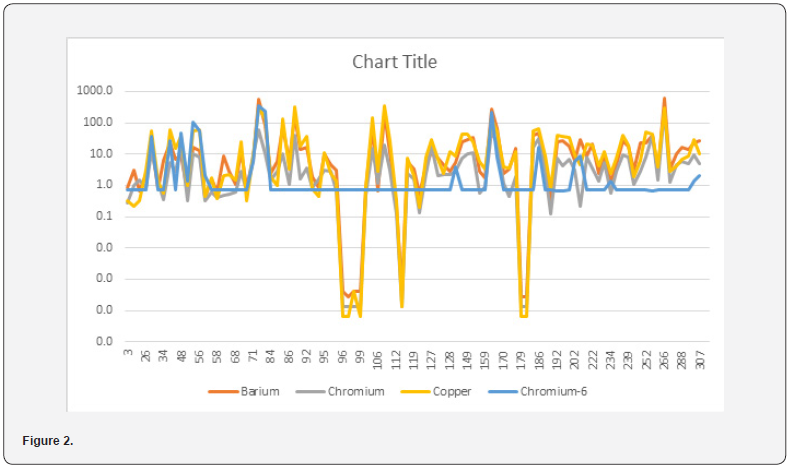

Human Biomonitoring: Human biomonitoring was applied to determine exposure to chromium and copper. All workers with potential exposure could participate, on a voluntary basis, in the human biomonitoring programmer. In addition, any individual on site with concerns about potential exposure could participate in the programmer. Essentially, two sampling protocols were established: one for persons that would enter the contaminated areas only once and another for operators that were expected to be more frequently in contaminated areas. All persons were requested to provide a urine sample at the beginning of the first day of activities, prior to any activity (null sample). For the persons with single exposure potential, a urine sample was collected at the end of the working day with potential exposure and another urine sample two days later. For operators with activities in the contaminated areas over a prolonged time period, urinary samples were collected at the end of the day prior to the last day of the shift. In addition, workers could provide end-ofshift samples on other days if they suspected that they might have been exposed (Figure 2).

Reference values for worker exposures (air, urine): Regular national occupational exposure limits, supplemented by limit values from professional organizations such as the ACGIH®, were used to evaluate air monitoring results. For Cr(VI) urine analysis, based on the documentation of the Threshold Limit value set by the ACGIH® and the relationship between airborne and urinary Cr(VI) as given in the documentation by the DFG, a biological limit value was set at 62.25 nmol (total Cr)/mmol creatinine and the background value for the non-exposed population at < 0.76 nmol (total Cr)/mmol creatinine [2-4]. Timing of urine collection was deemed less critical given the relatively long apparent urinary halflife of 15 to 41 hours [5]. For the urinalysis of copper, no biological limit value was set due to lack of consistent data whilst the natural background in the non-exposed population was considered to be less than 0.025 μmol/mmol creatinine [6]. The applied reference values are listed in Table 7.

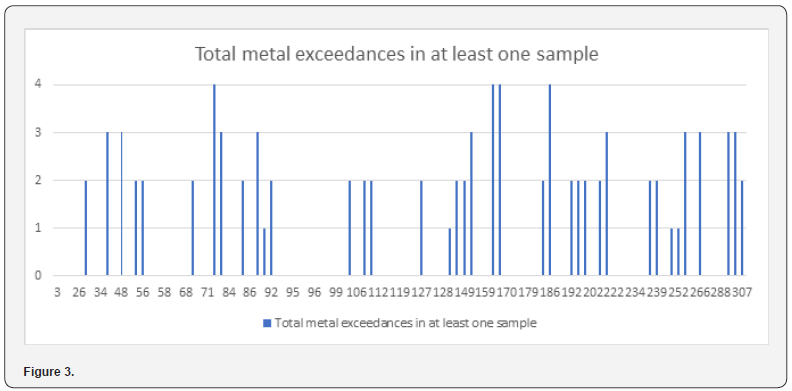

Reference values for surface contamination: Soon into the incident it was found necessary to adopt a set of health-based reference values for the level of surface contamination for the main hazardous catalyst components, in addition to the occupational exposure limits for inhalation exposure. On-line literature searches pointed to guideline values issued by the US Department of Energy (DOE) for surface contamination of laboratories where workers are engaged in processing beryllium containing materials. The guidelines consist in a Housekeeping Criterion and a lower Release Criterion in μg Be/100 cm [7]. The authors suggested that the guideline values could be adapted for surface contamination guidelines for other hazardous metals by using a conversion based on comparison of their inhalation exposure limits with the beryllium limit. In view of the time pressure on the need to assure worker health protection in the incident follow-up this pragmatic approach was implemented for the affected plant. The adopted values for barium, copper, total chrome and hexavalent chrome are listed in Table 7. In the situation present only the Release Criteria were applied. Surface contamination results above these criteria implied that further cleaning was mandatory before any other work could be done and area access was only allowed under full PPE. For shipping of scrap material of the demolished plant for disposal off-site, the housekeeping criteria were doubled based on the assumption that there would be no manual interventions by workers on this material (Figure 3). If scrap material was found to exceed the housekeeping criteria, further cleaning was required before authorizing shipment off-site [8].

Risk communication and employee assistance programmer: For risk communication a map of the impacted area was maintained on which the contamination level and required PPE were indicated by different colors, green meaning below Release Criteria. When a unit was cleaned and the measurements indicated that it was sufficiently cleaned, it was made green on this map. On the site itself, the difference between contaminated and clean areas was demarcated with fences. An information and mental support programmer were set up that comprised information sessions for all workers, organized on day 3 after the incident. These sessions contained information about possible toxicological effects of the released substances, information on the biomonitoring programmer and about possible stress reactions after an incident. An EAP (employee assistance program) was set up immediately after the incident with individual support available from 6 am until 11 pm on the first 3 days following the incident and scaled down afterwards to office hours for another period of two weeks. Employees and contractors were free to come in during opening times. In addition, group sessions were organized over the course of 3 weeks. Both support options were delivered by trained professionals from a professional trauma support organization. In addition, two information meetings were organized for neighbors.

Results

Local communities

In the air samples that were taken in the hours following the incident very little, if any, volatile organic chemicals (VOCs) were detected (Table 2). Especially in the communities north of the river, that were located in the direction of the wind, no detectable levels were measured. However, at the site entrance gate a transient rise in concentrations for a large series of VOCs were detected (all concentrations well below 0.5 mg/m3) about 5 h after the incident. It should be noticed that no ethylbenzene was detected in any of the measured locations with exception of a very low concentration (0.017 mg/m3) in a rural area. In the surface swipe samples that were collected within 24 h following the incident several metals could be measured, in particular Cr, Cu, Ba and Zn above the average Dutch background concentration, were found in samples collected at the site entrance and in several communities north of the river. When increased levels of Cr, Cu and Ba were found concomitantly, it was considered a very strong indication that catalyst debris had been deposited (Table 3). Cr(VI) levels were not elevated. Two days after the incident, the levels were significantly lower. At the site entrance the levels were, albeit lower than immediately after the incident, still higher than the average Dutch background, but in the communities the levels for Cr, Cu and Ba were back to background levels (Table 4). Twelve days following the incident, levels at the site entrance were still elevated above the background and in some rather remote communities Cr and Cu (but not Ba) could be detected over background levels (Table 5). In the grass samples that were collected within 24 h after the incident, concentrations of Cr over the background level were found at the site entrance; in two of the communities north of the river, levels of Cr and Cu over the background were found but Ba (although elevated at both locations) was only over background in one site (Table 6).

Values in bold are above the average Dutch background concentrations [8].

Values in bold are above the average Dutch background concentrations [8].

Values in bold are above the average Dutch background concentrations [8].

Values in bold are above the average Dutch background concentrations [8].

Industrial site

Air monitoring: During cleaning of the impacted area (10 months period) several days air monitoring was performed down wind of the cleaning location. Most samples were taken in the first weeks of the cleaning activities. Nearly all results were below the detection limit, see Table 8.

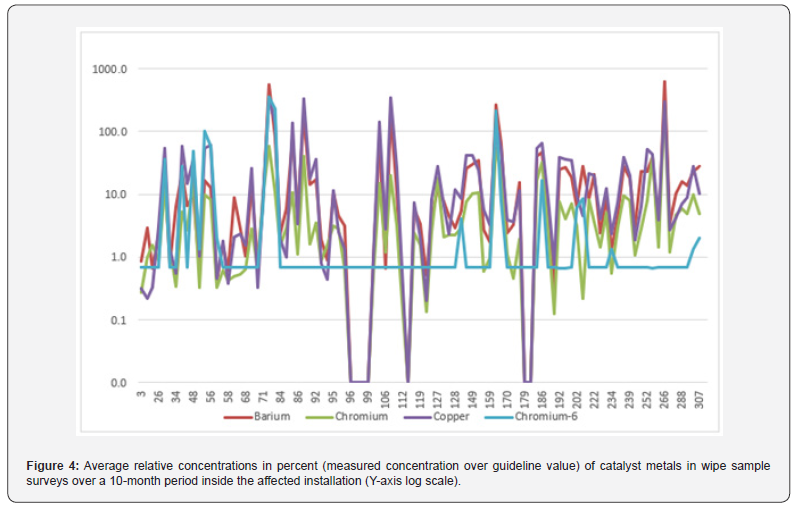

Surface monitoring: Over a period of ten months, 103 surface contamination surveys were conducted with a total of nearly 1500 samples (100 cm2 wipes for smooth surfaces and 100 cm2 vacuumed on rough surfaces, mainly asphalt roads). The number of samples per survey ranged from 2 to 76. The surveys were targeted towards specific components of the installation based on operational needs for clean-up, repair and demolition. During the later stage of the repair and demolition programmer, surface contamination sampling was also conducted in a temporary dedicated wash-down area and on scrap metal prior to sending off-site.

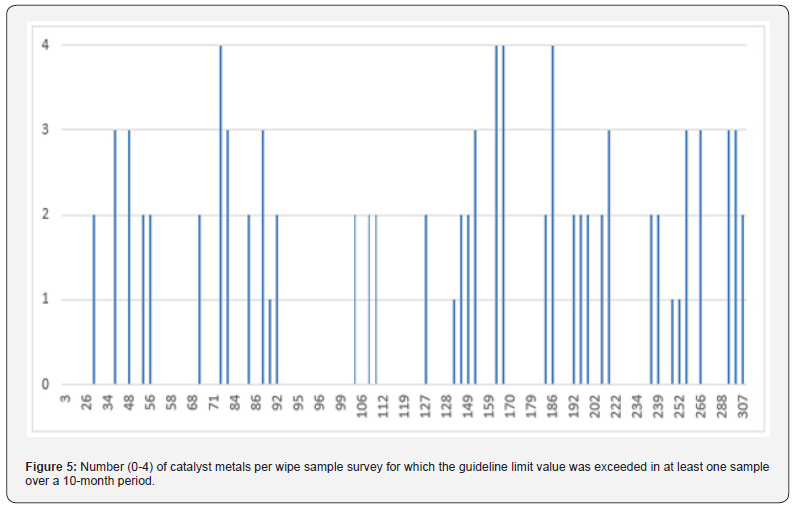

A key feature of the surface contamination survey programmer was the rapid (overnight) analytical feedback which was used to constantly update a map of the plant. Areas with excessive contamination were shown in red and access was only allowed under full personal protective equipment. Even if only one of the metals in one sample exceeded its guideline limit value the area remained red on the map. Areas with levels below all guideline limits were indicated in green and areas still requiring further testing were indicated in white. A summary of all surface contamination results is provided in Figure 4 (detailed data in Table 9 - supplemental material). An important finding of the surface contamination survey programmer was that the vast majority (>95%) of analytical results for hexavalent chromium was below the detection limit of 0.1 μg/100 cm2, even in many cases where one of the other metals exceeded its guideline limit value and hence the area remained ‘red’ on the map. Only in 10 out of the 103 surveys did one or more surface samples exceed the guideline limit value for hexavalent chromium and always in combination with an exceedance for at least one other metal. Barium exceeded its guideline limit value in 31 surveys in at least one sample; total chromium in 11 surveys; and copper in 36 surveys (Figure 5).

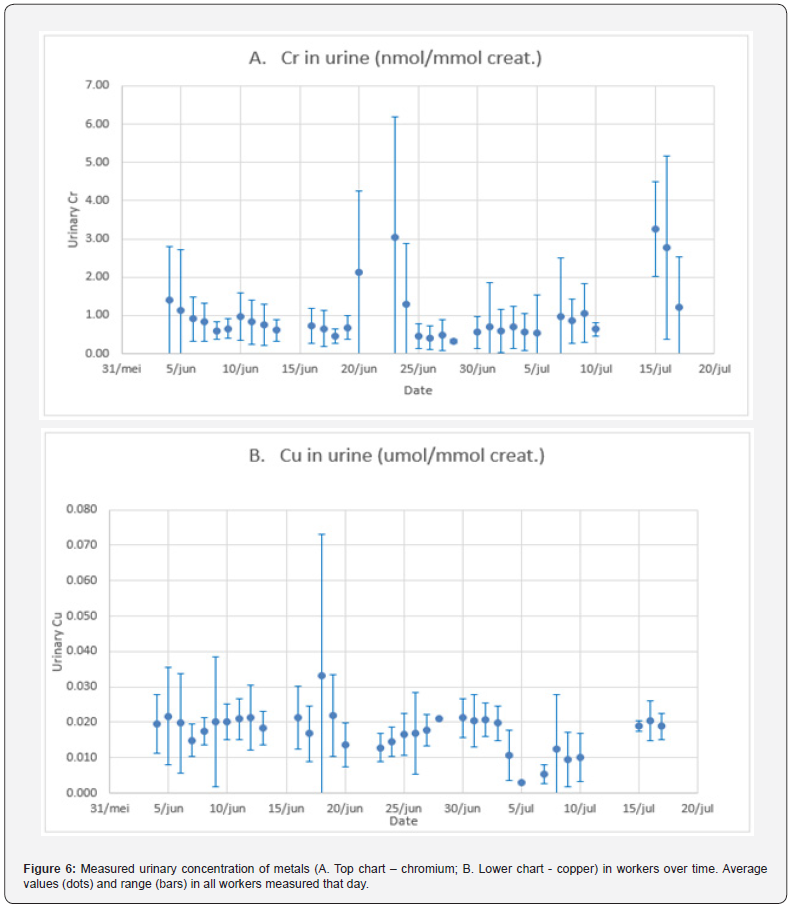

Biological monitoring: Over the course of 7 weeks immediately following the incident, a total of 990 urine samples were collected from 419 individuals, comprising emergency responders, workers involved in cleaning and demolition, investigating authorities, as well as individuals with concerns about their potential exposure. Where possible, initial samples prior to their first work shift with potential exposure related to the incident were collected to establish individuals’ baseline. In several individuals further samples were collected beyond the initial sample and the sample following the first shift with potential exposure. The total number of samples for an individual ranged from 1 to 14. For summary calculation purposes non-detect values were replaced by half the detection value of the specific sample. All summary urine analysis results by date are presented in Figures 6A and 6B. In 984 samples Cr was determined and the concentrations measured ranged from below detection limit up to 16.97 nmol/mmol creatinine, with and average value of 0.93 nmol/mmol creatinine and a median value of 0.60 nmol/mmol creatinine. In 989 samples Cu was determined and the concentrations ranged from 0.002 up to 0.156 μmol/mmol creatinine and an average that equaled the median at 0.018 μmol/mmol creatinine.

Of the 984 samples that were analyzed for Cr, 263 were collected prior to the beginning of the first shift with potential exposure related to the incident. In these samples an average of 0.81 nmol Cr/mmol creatinine was found (median: 0.59 nmol Cr/ mmol creatinine; range 0.13 - 10.53 nmol Cr/mmol creatinine). For 268 individuals initial samples were analyzed for Cu with an average value of 0.020 μmol/mmol creatinine (median also 0.020 μmol Cu/mmol creatinine; range 0.002 - 0.069 μmol Cu/ mmol creatinine). Results from a first sample following a shift with potential exposure were available for Cr and Cu for 353 and 351 individuals, respectively. The average Cr concentration in the 353 samples was 1.02 nmol/mmol creatinine (median 0.61 nmol/ mmol creatinine; range < LOD - 9.07 nmol/mmol creatinine). The average concentration Cu in the 351 samples was 0.018 μmol/mmol creatinine (median 0.016 μmol/mmol creatinine; 0.002 - 0.034 μmol/mmol creatinine). Three hundred sixty-eight results from a second and later samples were available from 170 individuals for chromium with average of 0.93 nmol/mmol creatinine (median 0.59 nmol/mmol creatinine; range < LOD (0.02) - 16.97 nmol/mmol creatinine). Similarly, 369 results from 169 individuals showed copper results of average 0.016 μmol/ mmol creatinine (median 0.016 μmol/mmol creatinine; 0.002 - 0.090 μmol/mmol creatinine) in second and later samples.

Employee Assistance programmer support: About 25 group sessions were conducted by trained psychological trauma professionals. Approximately 50 individuals made use of the individual EAP support offered in the weeks following the incident. For individuals who required more extensive support the programmer was continued for a longer period.

Discussion

The loud explosion and the fire that followed upon it raised significant environmental health concerns for the local communities as it was feared that both the volatile solvents and the catalyst-containing debris resulting from the explosion might be transported off site by the wind. With regard to the volatile organic solvents, at the time of the explosion, the reactor contained only ethyl benzene which has a relatively low acute toxicity with Dutch intervention values (LBW, life-threatening value, comparable to AEGL-3) around the explosivity value. Moreover, it was expected that most of the solvent would have been burnt in the fire. Indeed, ethyl benzene was not measured at the perimeter of the site but only approximately 5 km downwind in a rural area at a trace level (17 μg/m3) (Table 2). At the time of the explosion and the fire, a weak southernly wind was blowing which caused the smoke from the fire to pass from the industrial site to the communities across the river on which the chemical installations are located. Immediately following the incident air samples were taken for determination of volatile organic compounds. No significant increases in any of the compounds measured were found in the samples collected across the river. At the entrance of the industrial site for a number of compounds very low concentrations (ppb levels), orders of magnitude below the Dutch intervention values, could be detected (Table 2). Directly after the explosion and during the subsequent days, also wipe, soil and grass samples were collected and analyzed for metals. At some places in the communities directly downwind copper, chromium and barium, metals thought to originate from the catalyst material used in the exploded installation, were detected in surface wipe samples and in grass samples (Tables 3-6).

The concentrations were found to have declined to normal background levels in almost all grass samples taken 3 days following the incident. Most likely, this was the result of the rainfall during those days. The surface wipe samples showed low concentrations for several metals which were at a level not considered to pose a human health hazard. The concentrations seemed to decline over time. In the wipe samples collected two weeks after the incident only slightly elevated concentrations of copper and chromium could be measured in some places. It was expected that these concentrations would further decline and would return to normal background levels in the weeks to follow. Based on these results and the subsequent advice from the national authorities, the local authorities released all precautionary restrictions previously imposed. From the potential contaminants that were released during the explosion and spread over the industrial site, hexavalent chromium was considered to be the most critical contaminant in terms of potential health effect. As exposure could potentially occur by inhalation of small particles and contaminated dust as well as by dermal contact, environmental sampling campaigns for catalyst debris dust in air and for surface contamination were undertaken. The air sampling results were all very low, possibly due to the cellulose fixation that had been carried out and these campaigns were discontinued two months after the incident, as there was no indication of an elevated background level of catalyst metals in air.

On the other hand, the wipe sampling campaigns, targeted towards suspect areas, continued to return occasional elevated levels of catalyst metals over the entire period of clean-up and demolition of the damaged plant and proved very informative to continuously refine the area access restrictions and personal protection equipment requirements for staff. From very early on in the aftermath of the incident it was decided to conduct biological monitoring on workers to detect any inadvertent exposure during the incident and subsequently to verify that procedures to prevent or limit exposure and the use of personal protective equipment were effective. Apart from chromium also copper was measured in urine samples that were collected at designated time points over a period of about 7 weeks. Overall, the biomonitoring measurements for both copper and chromium showed that there was very limited internal exposure. As shown in Figure x A, the post-shift? values for urinary chromium varied over time and were occasionally higher than the background value of < 0.76 nmol (total Cr)/mmol creatinine for the non-exposed population but stayed well below the Dutch? limit value for chromium of 62.25 nmol (total Cr)/mmol creatinine. This indicates that only limited internal exposure had occurred in some instances, and that the procedures and protective equipment were generally effective. The biomonitoring values for urinary copper corroborate this (Fig x B) as the vast majority of values measured were within the normal range of less than 0.025 μmol/mmol creatinine for the non-occupationally exposed population.

A number of learnings were derived from the incident follow-up:

i. Fixation of catalyst dust and debris with a foam appeared

to prevent effectively the re-suspension in air of dust by wind;

ii. Demarcation of the affected area, controlled access

only under full PPE, decontamination when leaving the area

prior to doffing PPE to prevent spreading of contamination was

continually updated by the environmental sampling results, in

particular the wipe samples.

iii. Essential to have science-based health reference values

for hazardous materials on-site, for example OELs, even though

some conversion calculations may be needed depending on the

nature of the incident for guidance and interpretation of measured

levels in various matrices; for chemicals for which such values are

not available a rapid procedure to derive them in case of need is

very valuable. In the present case a value derived for Beryllium

was successfully transposed to other elements.

• Not all incident scenarios, and hence the nature and

level of contamination, are easily foreseeable

• to base such incident guidance values on chronic health

effect studies is appropriate and precautionary for occupationally

exposed persons engaged in clean-up and demolition work over a

period of several months

iv. The use of established industrial hygiene methods

and validated analytical procedures, whenever available, adds

confidence to incident response and follow-up

• in the early incident stage, a rapid turn-around of

sampling results, for example overnight, is important to verify

that protective measures are effective or are corrected before any

health effects occur; this applies equally to urine analysis results.

v. Biological monitoring if feasible for the chemical hazard

of concern, preferably non-invasive such as urine analysis, greatly

contributes to generating confidence among the workforce

• the measured levels in the urine of the participating

workers were frequently above background levels for nonexposed

populations, indicating that some exposure had

occurred. However, all values were well below the biological limit

values indicating that the applied control measures, including

PPE, were effective. It also illustrates the importance of having

general population levels and biological limit values for hazardous

substances.

• the worker population concerned was generally very

familiar with biomonitoring and in fact there were many workers

who asked to be allowed to provide urine samples. Human

biomonitoring such as the type implemented in the incident

follow-up is now a well-established technique in the chemical

industry to help control exposure to health hazardous compounds

and should be exploited to its full potential whilst continuing to

respect all personal privacy requirements.

vi. The combination of above techniques has enabled

effective management of worker exposure to health hazards in

incident response and the subsequent clean-up and demolition

operations

vii. Effectiveness and appreciation of EAP programmer:

the fact that a call-off contract for trauma support was in place

made it possible to organize a full support programmer within

24 hours following the incident. The availability and high level of

professional support was highly appreciated both by the workers

and the local management. Although not thoroughly investigated,

the assumption is that the existence of such a program prevented

more/longer lasting mental health problems. It was seen as good/

best practice.

viii. The general information sessions on day 3 were

positively received, the sessions were perceived as open, giving

clarity on possible health risks and showing care. These sessions

are clearly most useful when organized as soon as possible,

bearing in mind that there is some time needed to have sufficient

and validated information to share.

Conclusion

In the event of an explosion and fire in an industrial installation attention is usually quickly turned to the main raw materials and products and their health and environmental hazards, but focus should also be on auxiliary materials such as process catalyst, as in the reported case study these turned out to be principal compounds of concern.

In the current studies, the main findings were:

i. No indication of exposure above any occupational or

public health limit, which is due to proper occupational health

management, erring on the safe side in combination with an

established culture of human biomonitoring.

ii. The importance of rapid access to analytical facilities.

iii. The ability to develop guideline values (e.g. limit values

for swipe samples) at short notice (due to established practices).

iv. Good existing working relations between the site,

company health services and the regulatory authorities are

essential to allow rapid effective communications and deployment

of required services.

v. The importance of good management of psychological

stress/trauma due to proactive management of potential

traumatic incidents.

vi. The proper recording of learnings with regard to

prevention for reoccurrence of this type of incident.

Acknowledgement

The assistance of Marcel van Kruining and Mathieu J.P. van Puijvelde in collecting the on-site samples during the cleanup phase and the medical assistance, including the employee assistance programmer, during the entire process by Liesbeth C.M. Verheugd are gratefully acknowledged.

Conflict of Interest

Dr. Peter M.J. Bos declares no conflict of interest. Prof.dr. Peter J. Boogaard and Jan H. Urbanus were employed by Shell companies at the time of the incident and the subsequent investigations but declare that they totally free to design and conduct the research and express their own scientific opinion without any obligation to Shell.

References

- 2015.

- Boogaard PJ (2009) Biomonitoring of the Workplace and Environment, in General and Applied Toxicology, Third Edition, B Ballentyne, Marrs T, Syversen T, Editor. Wiley: Chichester, UK pp: 2559-2589.

- DFG, MAK- und BAT-Werte-Liste (2023) Ständige Senatskommission zur Prüfung gesundheitsschädlicher Arbeitsstoffe. Mitteilung 59.

- ACGIH, TLVs, BEIs (2023) based on the documentation of the threshold limit values for chemical substances and physical agents & biological exposure indices. Cincinnati, OH, USA.

- Tossavainen A (1980) Application of mathematical modelling for assessing the biological half-times of chromium and nickel in field studies. Br J Ind Med 37(3): 285-291.

- Lauwerys, RR, P Hoet (2001) Industrial Chemical Exposure - Guidelines for biological monitoring (3rd Ed). 48(4): 638-684.

- (2017) Brookhaven-National-Laboratory, IH75190 - Surface wipe sample for metals (rev. 23). Pp

: 1-16. - Mennen MG, NJC Van Belle (2007) Emissies van schadelijke stoffen bij branden (Emissions of dangerous substances by fires).