Impact Forces During Postharvest Handling Influence Internal and External Bruising of Vegetables

Danielle A Smith1, Desmond G Mortley2*, Aniel Rochester3 and Heshmat A Aglan3

1Department of Agricultural and Environmental Sciences, Tuskegee University, USA

2George Washington Carver Agricultural Experiment Station, Tuskegee University, USA

3Department of Mechanical Engineering, Tuskegee University, USA

Submission: October 26, 2018; Published: March 13, 2019

*Corresponding author: Desmond G Mortley, George Washington Carver Agricultural Experiment Station, Tuskegee University, Tuskegee AL, 36088, USA Introduction

How to cite this article: Danielle A Smith, Desmond G Mortley, Aniel Rochester, Heshmat A Aglan. Impact Forces During Postharvest Handling Influence Internal and External Bruising of Vegetables. JOJ Hortic Arboric. 2019; 2(3): 555586. DOI:10.19080/JOJHA.2018.01.555586

Abstract

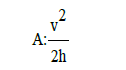

Experiments were conducted to determine the produce-to-produce impact simulated using a force transducer, and drop tests from various heights on tomatoes, blueberries, watermelon, okra and summer squash. Fruits from the species were subjected to various impact and compression forces ranging from 2N to 14N using a force transducer which exerts forces at a designated acceleration and velocity. In the drop tests, fruits were dropped from heights ranging from 5 to 40cm in 5cm increments unto a stainless steel, cork or cardboard surfaces until there were visible signs of external bruising. Internal bruising was assessed on a 5-point severity rating scale with one (1) is equivalent to fruits free of bruising, with no visible damage and five (5) corresponding to fruits with severe internal bruising. Impact and compression forces produced internal and external bruising on all four species. Blueberries (5.1±0.79 N), okra (6.8±0.79 N) and tomato fruits in the “pink and turning” stages of ripening (8.8±1.41 N and 7.2±1.99 N), respectively, were more susceptible to impact damage than summer squash and watermelons. Dropping squash and okra from any height on any of the surfaces resulted in injury. The magnitude of injury for blueberries was greater on stainless steel (hard surface) while ripe tomatoes dropped on a soft surface (cork) showed more internal injury damages than on hard and cardboard surfaces. These results suggest that blueberries, okra and tomatoes are more susceptible to impact damage than summer squash and watermelons.

Keywords:Food waste Bruising Okra Tomato Blueberry Squash Watermelon

Introduction

The demand for horticultural crops is expected to double as world population reaches 9.1 billion by 2050. Increasing the quality and quantity of food in response to growing demand will require increased agricultural yield, improved postharvest handling and processing to reduce the loss and waste of food - amount of edible food [1].

In the United States, for example 30% of all food, worth $48.3 billion, is thrown away each year [2] because of physical damages, rotting, pests, and consumers demand for “perfect” produce. Postharvest losses can be economic (loss of value), physical (weight loss or decay), cosmetic (bruising and scarring) and nutritional [3].

Horticultural crops are exposed to short-term impact forces along the food production value chain impacts that can cause puncture or bruising injuries. Bruising is a type of hypodermal tissue failure without rupture of the skin of fresh produce accompanied by discoloration of injured tissue [4]. Bruising of produce along the supply chain is a common problem and is one of the major physical defects contributing to postharvest loss of fresh horticultural produce [4]. The most common causes of bruising are extreme compression and impact forces with, compression being more common, including damage that occurs during harvesting when bins are overfilled and stacked. During loading, transportation and storage. Further, external factors such fruit size, shape, water stratus and firmness, and internal factors such as cell wall strength, elasticity, cell shape and internal structure can affect the potential and severity of bruising [4], and mechanical injury provides sites for pest attack and increases physiological losses [5].

Okra and summer squash will quickly lose weight if not immediately cooled and stored under high humidity. In addition, fresh okra bruises easily and blacken within a few hours hence requiring prepackaging in perforated film which is helpful to prevent wilting and physical injury during handling [6]. Tomatoes should be picked at optimum maturity for best quality and shelf life and can be ripened before sale to increase market value. When harvested at the breaker stage, the fruits can be handled and shipped with less damage than produce with more color [7]. Blueberries must ripen on the plant and be cooled quicklyafter harvest and protected from compression damage during shipping and marketing using small consumer packs (clamshells). Watermelons are packaged, in marked cardboard bins and carefully inspected to ensure that there are no sharp objects, which may damage the fruit, and ensure minimum handling of melons, as extra handling is expensive and may harm the produce [8].

Since horticultural crops are sensitive and susceptible to impact, reducing the number of times the commodity is handled lessens the amount of mechanical damage. The skin of the produce is an effective barrier to most of the opportunistic bacteria and fungi that cause rotting well as stimulates physiological deterioration and dehydration [5]. Harvesting, handling, packing, transportation and distribution of horticultural produce involve numerous mechanical operations which increase the likelihood of impact-related bruising. The force, acceleration and velocity of impacts will determine whether impacts can cause puncture injury resulting in qualitative and quantitative losses. As with repeated produce-to-produce impacts, extreme compression can also cause bruising watermelons and tomatoes.

Our objective was to determine the produce-to-produce impact forces simulated using a force transducer and drop tests from various heights that cause bruising of tomatoes, blueberries, water melon, okra and summer squash.

Material and Methods

Tomatoes, watermelon, okra and summer squash were grown at the George Washington Carver Agricultural Experimental Station, Tuskegee University, Tuskegee, Alabama (lat. 30.27°N, long, 85.42°W), May to August 2016, in a field containing a Norfolk Sandy loam. Plants were grown under white plastic mulch using standard cultural practices, drip irrigated and fertilized based on soil test. Fruits were harvested based on maturity or ripeness as needed while blueberries were harvested from existing 10-yearold plants.

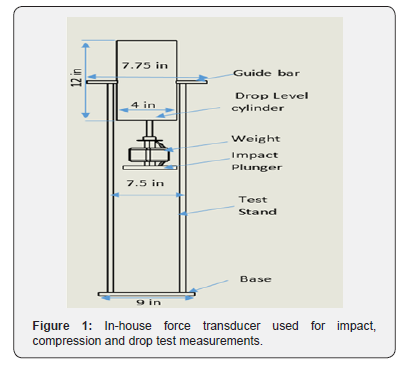

After fruits were harvested, 32 were selected and randomly separated into four groups of eight each. The fruits were subjected to compression and impact measurements and drop tests using a force transducer designed by the College of Engineering at Tuskegee University (Figure 1). The device works by exerting force at a designated acceleration and velocity. Different forces (mass in kg) were affixed to the plunger which was dropped from a desired height to impact the samples.

In the drop test, fruit samples were dropped from heights ranging from 5cm to 40cm unto either a stainless steel (hard), cork (soft) cardboard (medium) surface repeatedly in successive 5cm height increments until there were visible signs of external bruising. The internal bruising was determined after 6 days of storage [9] by sectioning samples with a sharp blade at the point of impact that was typically on the fruits equator (side) or on the top of the fruit near the stem scar. The magnitude of bruising was determined based on a 5-point severity rating scale following the methodology of Thompson et al. [9] where one (1) is equivalent to fruits free of bruising, with no visible damage and five (5) corresponds to fruits with severe internal bruising.

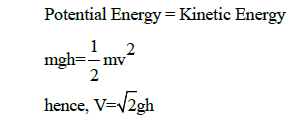

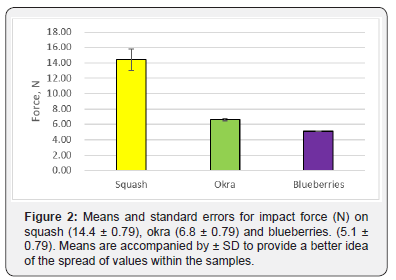

Impact energy was calculated using a derivation of the law of conservation of energy. The force from the falling weight was absorbed by the fruit samples and the potential energy from the drop test was equal to the kinetic energy of the fall. This energy is absorbed by the surface on impact. The damages from the impact forces and drop tests were calculated and assessed based on mass (m), velocity (V), acceleration (A) and force (F) using the following formulae:

hence,

Where: m= mass (kg)

g= gravity (acceleration due to gravity; 9.8 m/s2)

h= height (m)

v = velocity (m/s)

Where:

A= rate of acceleration (m/s2);

h= height (m)

v= velocity

F: Mass(kg) x Acceleration (m/s).

Due to a limited number of watermelons, only individual fruits were tested using a Carver Model 2697 Hydraulic Platen Laboratory Press. Each melon was placed between two flat steel plates and compressed at specified loading rates until impact damage occurred.

The experiment was conducted as a randomized complete block design with four replications. The data were combined by replication and analyzed by Analysis of Variance (ANOVA) and regression analysis (SAS, 2009). Least significant difference (LSD) between means was at 0.05 level of probability. Drop height damages were assessed based on velocity (V), acceleration (A) and force (F) using the formulas as outlined in chapter 3.

Results and Discussion

The mean impact forces on summer squash, okra and blueberries are shown in Figure 2. It took significantly more force (14N) to cause impact damage in summer squash compared to okra or blueberries. Visual inspection internally and externally of the summer squash showed both external and internal damage on the distal end of the fruits. The observed damage was manifested as small discolored indentations on the skin and cracks running vertically along the fleshier parts of the fruits. Similar results for impact and compression damages were observed for okra and blueberries. With okra, smaller forces (6N) caused fruit damage both internally, and externally manifested as bruising and cracking. Blueberries showed cracks and wrinkles on the skin with a marginally less force than that for okra (5N). Thus, both okra and blueberry fruits would be more susceptible to bruising and other injuries with very low forces and thus should be delicately handled.

The bigger the watermelon the more force it took to cause damage (data not shown) of varying degrees manifested as splits along breakage lines starting at the blossom ends. Internal damage was expressed as hollow spots after the pulp was displaced due to crushing from the compression forces. The mean pressed force was 258N produced by an average mass of 116kg.

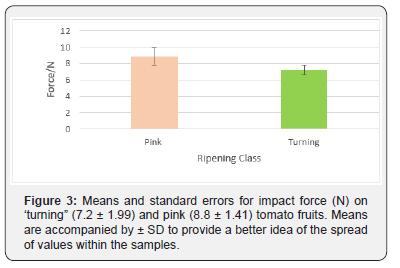

The mean impact forces on two different ripening stages of tomatoes (Figure 3). The showed forces above 7N cause bothinternal and external bruising of the fruits. The fruits showed surface splitting starting from the stem scar horizontally manifested visibly at the surface as a rupture of the skin through to the pulp. Fruits that were at the “turning” stage had a moderately high tolerance for impacts, and pink had a low tolerance. For example, fruits at the “turning” stage were bruised with a force of 7.2±1.99 N) which caused splits starting from the stem scar vertically causing the locular gel and seed contents to be expelled. Pink tomatoes were less prone (8.8±1.41) to splitting and showed moderate bruising. Therefore, these results suggest that more force was needed to bruise a pink tomato compared to those fruits that were in the “turning” stage of ripening.

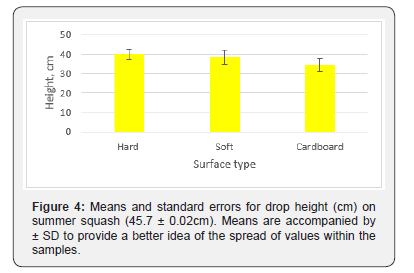

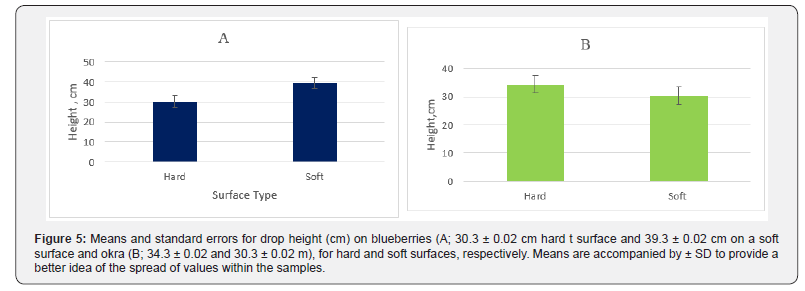

For drop tests (Figure 4), squash fruits that were dropped from any height unto any surface were bruised with the severity declining and was lowest when dropped on a cardboard surface. Thus, any drops above 40cm regardless of surface types will increase the severity of bruising on the fruits. Blueberries and okra (Figure 5) dropped from similar heights but only on stainless steel and the flat cork sheet surfaces because fruits must not bounce or be exposed to rebound impacts during drop tests [9]. Blueberries were bruised when dropped from a height of 30cm on the stainless steel (hard) surface and from approximately 40cm on the flat cork surface (soft). Therefore, bruising in blueberries increased with height of drop because of increased velocity on soft surfaces. Thus, the bruise damage was more severe on thecork sheet surface (soft) than the stainless steel (hard) surface because of the physics of impact. According to Thompson et al. [9] when a moving fruit contacts a surface its kinetic energy is transformed into alternative energy forms, including absorbed energy and when this exceeds critical levels, bruising occurs. The opposite response was observed for okra (Figure 5) which would be expected on a hard surface, in that drops above 30 cm on the stainless steel (hard) surface caused bruising.

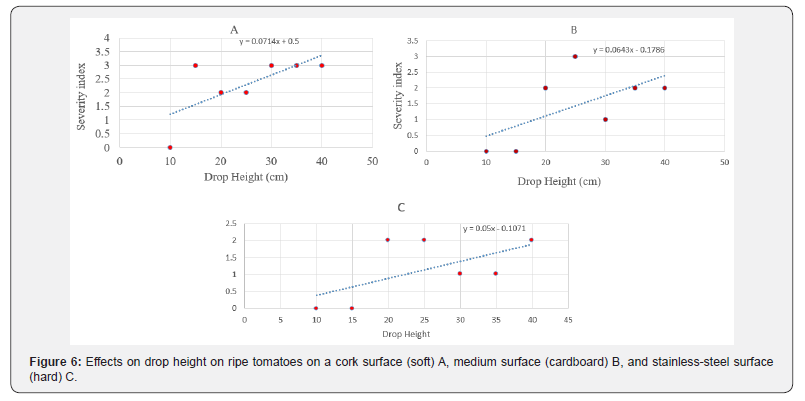

Effects of impact surface drop heights on internal bruising of ripe tomatoes on three surfaces (Figure 6) showed that the severity of internal bruising generally increased with drop heights. Drops above 35cm on stainless steel or cardboard surfaces caused average severity ratings of 2. This means that probably, the internal connection of the locular jelly and seed contents to the pericarp wall was broken. However, ripe fruits dropped on the cork felt sheet (soft) at heights of (26.7±0.03cm) had average severity ratings of about 3, suggesting that there was moderate internal bruising and therefore, the beginnings of hollow cavities forming between the locular jelly and the pericarp wall Thompson et al. [9]. This rating would be considered commercially important because packing-shed managers would report that these injury levels would translate into significant loss of raw product quality, since most splitting and bruising at the end of the postharvest handling chain was caused by fruit impacting against hard surfaces.

Conclusion

The results of the force transducer study support the thesis that it takes more impact forces to cause internal bruising in squash and watermelons compared to okra, blueberries or tomatoes. For the drop test, squash and okra exhibited bruising regardless of height compared to blueberries and tomatoes which bruised with increasingly greater heights especially when dropped on softsurfaces. Bruising reduces the quality of fresh produce, including fruits and vegetables.

Postharvest quality and quantity begin in the field and continue until it reaches the consumers plate. The postharvest quality status of the fruits in part depends on preharvest practices carried out during production. Understanding and managing the various roles that preharvest factors like fertilizer applications, pruning, maturity stage, cultivar selection and irrigation play in the quality of the fruits at harvest is critical in producing high quality fruits at harvest. The ultimate effect of this research was to provide farmers and consumers with healthy and safe fruits and vegetables with little or no bruise damage and higher returns to the growers. Practical suggestions from the studies include the fact that there is no doubt that harvesting, and handling of agriculture products have major effects on postharvest damage. Simple harvest methods can be adjusted and performed in ways to minimize production costs, but also considering issues that do not compromise the quality of the produce.

Acknowledgements

Contribution of the George Washington Carver Agricultural Experiment Station, Tuskegee University. This research was supported by funds from USDA/NIFA Capacity Building Grants.

References

- Buzby JC, Wells HF, Hyman J (2014) The estimated amount, value, and calories of postharvest food losses at the retail and consumer levels in the United States. USDA Econ Res Ser.

- Lundqvist J, de Fraiture C, Molden D (2008) Saving water from field to fork-curbing losses and wastage in the food chain. Stockholm Intl. Water Inst (SIWI) Policy Brief.

- Aggidis G, Arbon P, Brown C, Clarke C, Earp J, et al. (2013) Global food waste not, want not. Institution of Mechanical Engineers.

- Opara UL, Pathare PB (2013) Bruise damage measurement and analysis of fresh horticultural produce-A review. J Postharvbio 91: 9-24.

- Kiaya V (2014) Postharvest losses and strategies to reduce them. ACF Tech Paper, pp. 1-25.

- Kemble J, Musgrove MB (2004) Harvesting and postharvest care of okra. ACES ANR Bul 1062.

- Kemble JM, Tyson TW, Curtis LM (2004) Guide to commercial staked tomato production in Alabama. ACES ANR Bul 1156.

- ITF Net (2011) Watermelons - postharvest and processing.

- Thomson GE, Lopresti JP (2008) Impact collisions during handling and their effect on internal bruising and surface splitting of ‘Tempest’ tomatoes (Lycopersicon esculentum). New Zealand J Crop and Hort Sci 36: 41-51.