Abstract

This current work aims to present the performance evaluation procedures implemented at our department for the Quality Assurance of kV X-ray sources and detectors of the Cyberknife M6 system. The performance of the target locating system was evaluated in terms of the mechanical and radiation accuracy of both cameras and detectors. AAPM Report 74 is used to perform QA tests, including filtration, kVp accuracy, mA station exposure linearity, exposure reproducibility, and focal spot size. A multimeter device is used to check the above parameters.

Image position reproducibility is verified with the help of Isopost, Bad pixel statistics and leakage measurement of X-ray sources are also performed. The kVp accuracy is within ±5 kVp. The variation in mA station exposure linearity is < 0.1. The variation in exposure reproducibility is ≤ 0.05. The minimum filtration of the X-ray tube is also within the tolerance limit. The Imager position reproducibility is (0.0, 0.0) (Tolerance: ±1 mm). The leakage measurement is not more than 114 mR in 1 hour. The study concludes that the imaging system in Cyberknife is safe for both patients and staff.

Keywords:Quality Assurance; Isopost; Bad pixel; SNR; CNR; Gain stability

Introduction

In SRS and SBRT, single or multiple fractions of a high radiation dose are delivered to a well-defined small target. SRS has become an important treatment modality in the management of a wide variety of intracranial and extracranial lesions, offering the possibility of a significant reduction in dose to critical healthy tissues with substantial benefits to patients. The CyberKnife SRS system is a frameless radio surgery device that combines image guidance with robotic technology, aiming at the delivery of highly conformal dose distributions to intracranial and extracranial lesions with a standard uncertainty of < 1mm [1].

We have a Cyberknife M6 machine with a standard couch and G4 on floor images, which contains a a-Si detector. The X-ray sources are a conventional rotating anode tube. It has 2.5 mm of Al added filtration on the window side. The X-ray generators supplying high voltage power operate at 37.5 kW at peak power output and can deliver X-rays with technique factors of 40-125 kV, 40-300 mA, and 1-500ms. The QA principles and procedures described in AAPM Reports No. 14, Part 3 (Ref 23), and No. 74 of Task Group 12 (Ref 24) can be applied. TG-135 is also used for the QA tests [2].

Materials and Methods

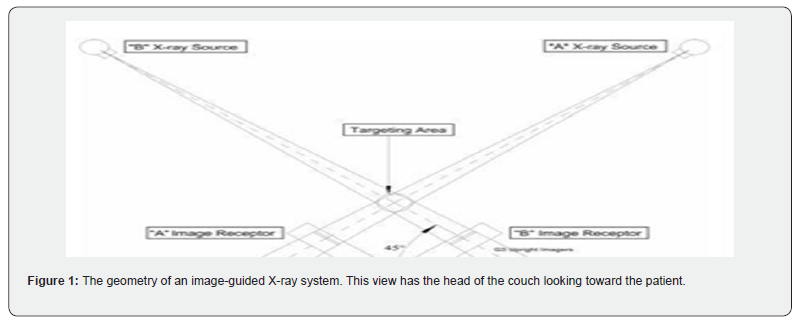

In this study, I have performed the QA test for different parameters for kV X-ray tubes. The tests that I have performed are filtration, kVp Accuracy, mA station exposure linearity, exposure reproducibility, Focal spot size, Imager position reproducibility, and Bad pixel statistics. For the measurement, I have used the solid-state detector and the multimeter. For Imager position reproducibility and bad pixel statistics, I have contacted the Field Service Engineer. In the radiation test SID is 100cm [3,4] (Figures 1-3).

Results

kVp Accuracy: Tol: ± 5 kVp (Tables 1 & 2) Filtration: (Tables 3 & 4)

Minimum filtration of the X-ray tube is:

1.5 mm of Al for kV ≤ 70

2.0 mm of Al for 70 ≤ kV ≤ 100

2.5 mm of Al for kV > 100

mA Station Exposure Linearity (Tables 5 & 6)

Exposure Reproducibility: (Tol: 0.1) (Tables 7 & 8)

Focal Spot Size (Tables 9 & 10)

Co-ordinates: (0.0,0.0) Co-ordinates: (0.0,0.0)

Imager Position: (Tol: ± 1 mm) Reproducibility (Figures 4 & 5)

Co-ordinates: (0.0,0.0) Co-ordinates: (0.0,0.0)

Bad Pixel Statistics (Figures 6 & 7) Leakage Measurement (Tables 11 & 12)

Since the Cyberknife machine is used for stereotactic treatment of intracranial and extracranial lesions with higher doses per fraction, with the intent to achieve ablation. To achieve this goal, intrafraction imaging plays an important role. For this purpose, images of the initial patient set up and during treatment can also be taken at short intervals with the help of an in-room imaging system. But due to mechanical or radiation errors, there are chances to get inferior quality images, which can result in excessive dose to the patient and will affect the patient’s treatment. To resolve this problem, we should perform QA for the kV X- ray tube on a regular basis. For Quality Assurance, we can follow the TG-135 recommendations [5].

The energy of the X-ray tube depends on the applied kVp. As we increase the kVp, the energy will also increase. The energy is directly proportional to kVp. mA controls the tube current of the X-ray tube. If we want more X-rays, we can increase the mA. By changing the mA, we can control the quantity of X-rays. So, we can increase mA to get more contrast because a larger no of X-rays will pass through the body. The variation in kVp Accuracy, mA station linearity, and exposure reproducibility can lead to unnecessary extra exposure to the patient, or it can affect the image quality [6].

The variation in filtration can allow more soft X-rays or increase the mA loading in the X-ray tube, which can decrease the life of the X-ray tube. The QA for filtration should also be performed periodically because the surface of the filter can be rough due to the penetration of X-rays several times. The size of the tube focal spot is inversely related to spatial resolution. So, the spatial resolution will be degraded if the focal spot is too large. The image sharpness will degrade. And if the focal spot is too small, the temperature of the focal spot may increase rapidly, and it will affect the lifetime of the x-ray tube. Also, it will lead to an increase in exposure time that results in patient motion and motion blur [7,8].

Conclusion

If the system’s Quality assurance is conducted routinely, it will result in optimum quality images with lower radiation dose. The Quality Assurance for the imaging system was conducted as per the established protocols. All the Quality Assurance parameters were found to be well within tolerance. The kVp accuracy is within ±5 kVp. The variation in mA station exposure linearity is also within ± 5%. The variation in exposure reproducibility is < 0.10. The variation in imager position reproducibility is also less than 1 mm. The variation of Bad pixel statistics and tube leakage is also under the tolerance limit. So, it can be concluded that the imaging system in Cyberknife is safe to use for both patients and the staff.

References

- R Adler, SD Chang, MJ Murphy, J Doty, P Geis, et al. (1997) “The CyberKnife V R: A frameless robotic system for radio surgery.” Stereotact Funct Neurosurg 69(1-4 Pt 2): 124-128.

- JS Kuo, C Yu, Z Petrovich, ML Apuzzo (2003) The CyberKnife VR stereotactic radiosurgery system: Description, installation, and an initial evaluation of use and functionality. Neurosurgery 53(5): 1235-1239.

- Annette Martin Quinn (2002) CyberKnife VR: A robotic radiosurgery system. Clin J Oncol Nurs 6(3): 149, 156.

- Christos Antypas, Evaggelos Pantelis (2008) Performance evaluation of a CyberKnifeVR G4 image-guided robotic stereotactic radiosurgery system. Phys Med Biol 53(17): 4697-4718.

- Martin J Murphy, James Balter, Stephen Balter, Jose A BenComo, Indra J Das, et al. (2007) The management of imaging dose during image-guided radiotherapy: Report of the AAPM Task Group 75. Med Phys 34(10): 4041-4063.

- Sasa Mutic, Jatinder R Palta, Elizabeth K Butker, Indra J Das, M Saiful Huq, et al. (2003) “Quality assurance for com puted-tomography simulators and the computed-tomography-simulation process: Report of the AAPM Radiation Therapy Committee Task Group No. 66.” Med Phys 30(10): 2762-2792.

- National Council on Radiation Protection and Measurements, Quality assurance for diagnostic imaging equipment: Recommendations of the National Council on Radiation Protection and Measurements (The Council, Bethesda, MD, 1988).

- K Thayalan (2014) The Physics of Radiology and Imaging: Physics of X-Rays.