Trends in the Manufacture and Design of Sustainable Cosmetics

Joanna Igielska-Kalwat1,2*, Ewa Kilian - Pięta2 and Sława Połoczaska-Godek1

1Faculty of Cosmetology, University of Education and Therapy Poznan, Poland

2Symbiosis Laboratory, Poznan Science and Technology Park, Poland

Submission:July 04, 2023; Published:June 14, 2023

*Corresponding author:Joanna Igielska-Kalwat, Faculty of Cosmetology, University of Education and Therapy Poznan, 61473, Poland

How to cite this article:Joanna I-K, Ewa K - P, Sława P-G. Trends in the Manufacture and Design of Sustainable Cosmetics. Curr Trends Biomedical Eng & Biosci. 2023; 21(4): 556067 DOI:10.19080/CTBEB.2023.21.556067

Abstract

The aim of the articles was to disseminate trends emerging in the production of sustainable cosmetics. For thousands of years, people have been looking for new ways to improve their appearance. Wanting to take care of their beauty, women and men all over the world, in addition to using the best cosmetics and treatments, want to introduce a sustainable beauty routine to mitigate the negative impact of consumerism on the environment. One of the most noticeable trends is the development of pro-environmental solutions applied in everyday life, but also in industry. Manufacturers are emphasising the production of more environmentally friendly raw materials. Conscious consumers, they choose cosmetics whose production is based on sustainability (Figure 1). The results that have been collected in this article show how to use waste from other industries to produce cosmetics. Consumer awareness on the manufacturer of cosmetics that are safe not only for human health, but also for the environment.

Keywords: Sustainable Cosmetics; Water Less; Upcycling; Zero waste; Respect the nature

Introduction

Sustainable development meets the needs of the present without compromising the livelihoods of future generations. Sustainable cosmetics starts with the product idea. Further steps involve sourcing raw material from sustainable agriculture in accordance with the Fair-Trade principle. This trend reduces the use of water and chemicals. Production should minimize energy consumption and harmful emissions, and the choice of appropriate packaging is important. Transport, sales and use are also part of sustainability. Finally, it is important to consider what happens to the product after it has been used, where the packaging will go, whether it can be reused, how it will affect the environment [2] Recently, the beauty industry has seen the development of trends that expand the idea of producing cosmetics based on natural, environmentally safe products. We can see water less formulations on the shelves. Cosmetics also contain potable water, which is a unique post-biotic waste product. Among other things, it contains proteins, oligosaccharides and isoflavones [3]. A substitute for water can be whey, which is a post-production waste from tofu (Back to Comfort’s ToforYou series) [4]. The liquid form has been replaced by cubes, concentrates or powders. We are seeing a greater emphasis by consumers and science centers on the use of raw materials that support sustainability. The market products on offer indicate a strong interest in ingredients that are by-products from other industries (upcycling). A notable example is the hair laminate from the Polish company Hairy Tale Cosmetics Seal the Deal, which contains hyaluronic acid and collagen extracted from fish skins, which are waste products from the food industry. Fish collagen resembles the protein produced in the human body. It is an all-natural ingredient that is free of impurities and has much better cosmetic properties than previously used types of collagens. Seal the Deal technology has been developed without using water (water less and water upcycling).

Fish skin, which is a waste product, would normally have to be disposed of. And by reusing them in the production of, for example, cosmetics, they have become part of the trend (upcycling) Figure 2 [5]. Manufacturers receive beneficial ingredients for cosmetics, reduce carbon footprint generation and support one of the most important trends - ZERO WASTE. The ZERO WASTE trend, which is extremely helpful for the preservation of our planet’s healthy development. For example, the oxyresveratrol created for the R-OXY and Resveravit-C AGE GLOW series from the Back to Comfort company in Poznan is obtained from furniture industry waste - breadfruit cuttings.

Upcycling trends in the beauty industry

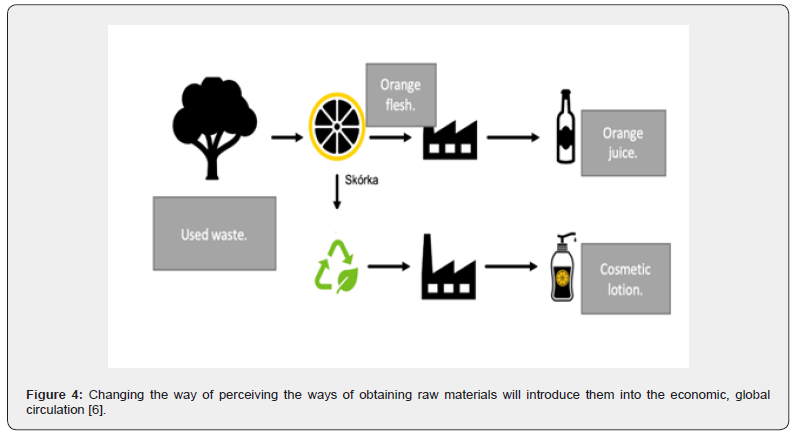

Upcycling trends in the beauty industry can be introduced by changing just one component. The traditional industry is focused on high-quality raw materials (Figure 3 & 4). The parallel use of raw waste reduces the amount of rubbish and landfill area by 4.5 tonnes per year. Causes a shift towards a closed-loop economy and reuse of by-products. CO2 released during the processing of 1 tonne of vegetable waste is saved. Tofu is a soy product obtained by coagulating soy milk. This process involves the assembly of particles of a dispersed colloidal phase into larger agglomerates forming a continuous phase with an irregular structure. As mentioned, whey, an unwanted by-product of tofu production, has been used as a primary ingredient in hair care products (TofurYou by Back to Comfort) Figure 5. Compared to water, whey technologically contains protein, oligosaccharides, flavonoids, mineral salts, vitamins (A, C, K, E and B), iron, phosphorus, potassium, sodium and choline salts [7-9]. Whey contains complete essential protein and essential amino acids that are not synthesised internally. It also contains unsaturated fatty acids, valuable omega-3 and omega-6. Tofu products contain a high amount of flavonoids, mainly their unique subgroup called isoflavones, including genistein and daidzein. Isoflavones have a positive effect on many aspects of our body’s functioning, hair and skin condition. Furthermore, the use of whey extracted from tofu in the production of hair cosmetics is part of both upcycling and green chemistry trends [10].

Raw material companies have also developed technology for many active ingredients that are created from waste or secondgeneration raw materials. The raw material TEGO Natural Citrus from Evonik (INCI: Citrus reticulate (tanerine) Pell Extract) was created from the peels of oranges, which are waste products from the production of orange juice. This substance used in the formulations is an antioxidant that gives the skin a radiant and uniform appearance. The raw material is also COSMOS-certified natural (Figure 6) [11].

Another proposal from Evonik is two raw materials, TEGO Sterol KCS and TEGO Sterol 7-DHC, extracted from sheep wool waste that could not be used for other purposes. TEGO Sterol KCS (INCI: Potassium Cholesteryl Sulfate), is a natural component of the extracellular space lipids of the stratum corneum. It is involved in the exfoliation process and stimulates the synthesis of fatty acids. It also acts as an emulsifier and emollient. On the other hand, TEGO Sterol 7- DHC (INCI: 7-Dehydrocholesterol) is a precursor of cholesterol and vitamin D3 biosynthesis. It regulates the process of cell differentiation and stimulates the synthesis of peptides that naturally protect the skin against microorganisms. It also protects it from UV damage, stimulates melanocyte activity and malanogenesis. It also contributes to hair protection (Figure 7) [13,14].

Also noteworthy is the company Ukviat, each of whose cosmetics supports the planet. The company donates 2% of sales to the MARE Foundation, which protects marine ecosystems, helps plant 0.5 m2 of biodiverse forest and donates funds from sales to a joint action with the Meadow Foundation [15]. The Anvene brand has joined the pur project, which aims to restore coral reefs; moreover, the brand’s cosmetics are safe for aquatic ecosystems. La prairie’s advanced marine biology tonic, on the other hand, has marine-derived ingredients as its main active ingredients, grown using scientifically controlled methods that protect the land environment. This is the best way to enjoy the benefits of marine plants while not depleting nature’s resources.

Ecological solutions for packaging selection

The trend towards eco-friendly products can also be observed in the packaging industry. It is very important that the raw material and the shape of the packaging can be recycled. Overly large areas covered with decorations should be avoided. A limited number of packaging materials should be used. Dark colour is important in the production of cosmetic packaging. Companies use raw materials that support the development of a recycling economy. As a result, manufacturers in the cosmetics industry are looking for alternatives that place less of a burden on the environment. Looking at this trend in packaging development, it can be seen that companies are attempting to replace plastic with cardboard, wood, glass or fully recyclable plastic [16]. The Polish company Serpol - Cosmetics uses PET and HDPE pellets and recycled rPET for its packaging. These plastics are in high demand. After plasticising the raw material, a preform is produced, which is then blown. The materials used for packaging contribute to weight reduction to introduce less plastic into the environment. The company uses packaging that is 100% recyclable [17].

Ecological labelling solutions

The next step should be to choose the right raw material for the label. Over the past few years, there has been an increase in materials that are ecological substitutes for standard plastics. Among the available proposals are self-adhesive materials. These materials support the reuse of packaging and promote recycling. These plastics are made from recycled and renewable raw materials. Materials that support the reuse of packaging are aimed in particular at companies seeking to maximize packaging recovery. This is made possible by the introduction of a specially formulated adhesive that allows the label to be completely separated from the surface of the packaging during the recycling process, leaving no residue. In contrast, materials that aid recycling use labels in which the adhesive used when PET bottles are ground makes the cut label float. In turn, the cleaned PET flakes sink to the bottom of the tank. The process looks similar when recycling glass bottles. During the bath of the resulting pestle, the shredded labels float to the surface [18,19]. Adhesives that support the recycling process make it possible to separate the label from the packaging at lower temperatures than before.There is a reduction in the energy required to heat the water. The formulation of adhesives has been developed in such a way that the water used in the recycling process is not contaminated, making it suitable for reuse [20].

Reduced materials are another important group of ecofriendly labelling plastics. The materials have a lower grammage, which contributes to generating a lower level of post-production waste. Along with the use of labels produced on thinner raw material, the company reduces packaging and transport costs and saves time when changing rolls. This has to do with the higher number of labels wound on them. An example is PE65 film material. For a roll of the same diameter, 12% more label material is wound. Reduced self-adhesive materials usually have the same or very similar properties [21]. Mention should also be made of labels that are manufactured from recycled raw materials. Their basic production premise is that they reduce the use of fossil fuels, water and energy. Household plastic and post-industrial waste are used to produce them. In addition, recycled plastic from PET bottles is also used [22]. It is also worth mentioning plastics that are produced from renewable raw material. This has a significant impact on reducing the consumption of fossil fuels and reduces carbon dioxide emissions due to the use of plant biomass. Selfadhesive plastics that are produced from renewable sources contain approximately 80% ingredients of natural origin. Often the raw materials used in the production of labels are paper produced from sugar cane, material made from natural wood, paper made from 100% cotton and bio films made from ethanol derived from sugar cane. PLA film, which is produced from lactic acid, is rapidly biodegradable [23,24].

Packaging Compatible With Nature

Of note are the bottles made from sugar cane. They are filled with natural mineralised water from Elmhurst Spring, used for facial cleansing. The bottle can then be filled with tap water and used as a source of hydration for the body. Sustainable reusable bottle. Of particular note is Neboa’s packaging, which produces according to the respect the nature philosophy, based on respect for our planet. The company has combined effective hair care with respect for nature at the same time. It has decided to have their packaging made from plastic harvested from the oceans. The company argues the idea through the slogan Assess is Life. The oceans cover a huge area of our planet. Around 80 per cent of the creatures that live on Earth live in the oceans. The oceans also regulate the Earth’s climate. They currently hold more than 300 MILLION tonnes of plastic. Every year, this number increases by another 8 MILLION TONS of pollution. Approximately 1 MLN birds and 100 THOUSAND mammals are killed each year by plastic waste. By producing packaging made from plastic caught from the oceans, the company is making a real impact on cleaning the waters of pollution, saving the lives of marine animals and protecting our future. Every Neboa pack, means less plastic in the oceans (Figure 8) [25].

Increasing consumer awareness and trends related to ecoresponsibility in cosmetic formulation technology and packaging have led manufacturers to pay attention to issues related not only to the safety and efficacy of cosmetic products. They are also supporting our safe home - our planet. Consumers also want the products they buy to be planet-friendly (Figure 9).

Conclusion

The trend towards eco-responsibility in formulation and packaging means that manufacturers, technologists and designers are outdoing themselves in creating and supplying raw materials and materials that respond to these trends. Cosmetics manufacturers have a range of options in terms of not only adapting packaging to legal requirements or consumer preferences, but also creating engaging, individual and personalized packaging tailored to a specific audience or even an individual consumer. The topic of trends is important. In this regard, the European Union requires manufacturers to make all plastic packaging recyclable by 2030, helping to reduce the waste and pollution generated. The measures taken by the European Union to implement the adopted strategy in the area of reducing the use of plastic in production are aimed at increasing the number of companies carrying out recycling processes in individual countries. All steps taken in this area focus on developing a recycling economy that relieves the burden on the environment. Choosing more environmentally friendly packaging also sends a clear message to consumers. The message that a manufacturer is taking action to protect the environment can often be decisive in whether or not a customer decides to buy a particular product.

Acknowledgment

Support from University of Education and Therapy and Symbiosis Laboratory is acknowledged.

References

- Stentiford ED, Lasaridi K (2011) ‘Upcycling’ organic waste in a world of thinly distributed resources. Waste Manag Res 29(11): 1115-1116.

- Ali S, Akter S, Fogarassy C (2021) Analysis of circular thinking in consumer purchase intention to buy sustainable waste-to-value (WTV) foods Sustainability. Sustainability 12: 5390-5398.

- Mont O, Plepys A (2008) Sustainable consumption progress: Should we be proud or alarmed? J Clean Prod 16(4): 531-537.

- Symbiosis Laboratory guide. Active Ingredients 2021.

- Igielska-Kalwat J, Kilian-Pięta E, Połoczańska-Godek S (2022) The Use of Natural Collagen Obtained from Fish Waste in Hair Styling and Care. Polymers 14(4): 749-760.

- Balaram V (2019) Rare earth elements-A review of applications, occurrence, exploration, analysis, recycling, and environmental impact. Geosci Front 10(4): 1285-1303.

- Jun JY, Jung MJ, Jeong IH, Kim GW, Sim JM, et al. (2019) Effects of crab shell extract as a coagulant on the textural and sensorial properties of tofu (soybean curd). Food Sci Nutr 7(2): 547-553.

- Rui X, Fu Y, Zhang Q, Li W, Zare F, et al. (2016) A comparison study of bioaccessibility of soy protein gel induced by magnesiumchloride, glucono-δ-lactone and microbial transglutaminase. LWT-Food Sci Technol 71: 234-242.

- Zhang T, Zhao Y, Tian X, Liu J, Ye H, et al. (2021) Effect of ultrasound pretreatment on structural, physicochemical, rheological and gelation properties of transglutaminase cross-linked whey protein soluble aggregates. Ultrason Sonochem 74: 105553.

- Timpanaro G, Bellia C, Foti VT, Scuderi A (2020) Consumer Behaviour of Purchasing Biofortified Food Products. Sustainability 12(16): 6297.

- (2021) Evonik company guide. Active Ingredients.

- Liu-Smith F, Meyskens FL (2016) Molecular mechanisms of flavonoids in melanin synthesis and the potential for the prevention and treatment of melanoma Mol. Nutr Food Res 60(6): 1264-74.

- Sato J, Denda M, Nakanishi J, Nomura J, Koyama J (2018) Cholesterol sulfate inhibits proteases that are involved in desquamation of stratum corneum. J Invest Dermatol 111(2): 189-193.

- Williams ML, Rutherford SL, Feingold KR (2017) Effects of cholesterol sulfate on lipid metabolism in cultured human keratinocytes and fibroblasts. J Lipid Res 28(8): 955-967.

- Ukviat company guide. Active Ingredients 2021.

- Gravina RJ, Xie T, Bennett B, Visintin P (2021) HDPE and PET as Aggregate Replacement in Concrete: Life-cycle assessment, Material Development, and a case study. J Build Eng 44: 103329.

- (2021) Serpol - Cosmetics company guide. Active Ingredients.

- Silva TR, Azevedo ARG, Cecchin D, Marvila MT, Amran M, et al. (2021) Application of plastic wastes in construction materials: A review using the concept of life-cycle assessment in the context of recent research for future perspectives. Materials 14(13): 3549.

- Shen L, Worrell E, Patel MK (2010) Open-loop recycling: A LCA case study of PET bottle-to-fibre recycling. Resour Conserv Recycl 55(1): 34-52.

- Mascarenhas ZM, Piao Z, Vasconcelos KL, Poulikakos LD, Bernucci LL (2022) Comparative environmental performance of pavement structures considering recycled materials and regional differences. Sci Total Environ 858: 159-162.

- Santos J, Pham A, Stasinopoulos P, Giustozzi F(2021) Recycling waste plastics in roads: A life-cycle assessment study using primary data. Sci Total Enviro 751: 141-148.

- Mashaan N, Chegenizadeh A, Nikraz H (2021) Laboratory Properties of Waste PET Plastic-Modified Asphalt Mixes. Recycling 6(3): 49-55.

- Enfrin M, Myszka R, Giustozzi F (2022) Paving roads with recycled plastics: Microplastic pollution or eco-friendly solution? J Hazard Mater 437: 129-134.

- Bare J (2011) TRACI 2.0: The tool for the reduction and assessment of chemical and other environmental impacts 2.0. Clean Technol Environ Policy 13: 687-696.

- (2021) Neboa company guide. Active Ingredients.

- Bridgens B, Powell M, Farmer G, Walsh C, Reed E, et al. (2018) Creative Upcycling: Reconnecting People, Materials and Place Throughmaking. J Clean Prod 189: 145-154.