Review on Evolution of Silicon Nitride in the Field of Orthopedics

Sachin Ghalme* and Yogesh Falak

Department of Mechanical Engineering, Sandip Institute of Technology and Research Centre, India

Submission: January 19, 2018; Published: February 02, 2018

*Corresponding author: Sachin Ghalme, Department of Mechanical Engineering, Sandip Institute of Technology and Research Centre, Nashik (MS), India, Tel: +919890464305; Email: sachinghalme@hotmail.com

How to cite this article: Sachin G, Yogesh F. Review on Evolution of Silicon Nitride in the Field of Orthopedics. Curr Trends Biomedical Eng & Biosci. 2018; 11(5): 555824. DOI: 10.19080/ CTBEB.2018.11.555824.

Abstract

Knee and hip replacements offer great relief to number of patients around the world. Silicon Nitride (Si3N4) is a no-oxide ceramic material initially developed for industrial applications operating at extreme conditions and demanding high strength along with fracture resistance. Recently silicon nitride is applied in the field of orthopedic for replacement of hip and knee. This review covers the information and generation of silicon nitride for joint replacement in the field of orthopedic, which will be useful for engineering and biomedical professionals.

Keywords: Silicon nitride (Si3N4); Orthopedic; Hip/knee replacement

Introduction

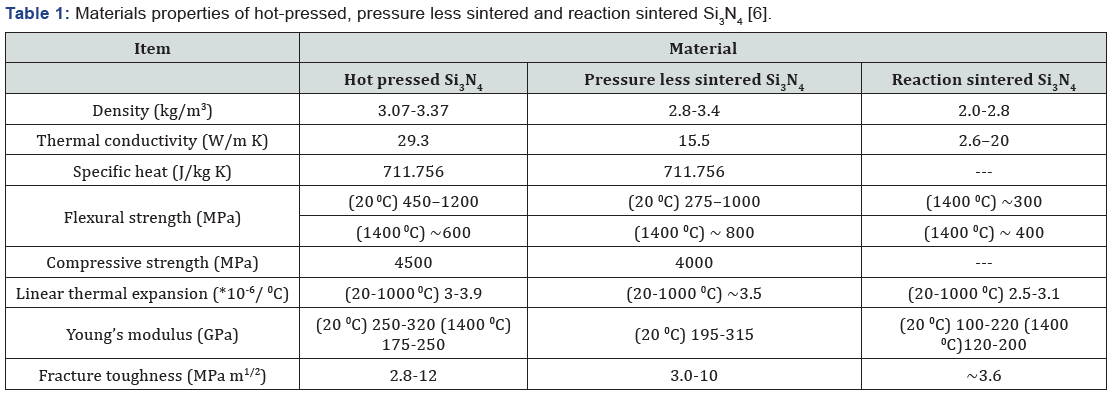

Silicon nitride is a non-oxide ceramic. It is an inorganic and non-metallic compound, made of silicon and nitrogen, vital elements for life [1-3]. It was discovered firstly 1857, but first synthetic silicon nitride was developed by Deville and Wohler in 1859 and came into picture when its commercial application began in 1950’s [4]. Silicon nitride is a strong, having low thermal expansion, high temperature stability, high wear resistance material to abrasion, corrosion and inert to most chemicals. It has highest fracture resistance than any other ceramic materials. All these properties made it suitable for various industrial applications suitable for extreme operating conditions also. In 1994 Poper [5] published a paper on the application of Si3N4 ceramics, which was based on computer-searching in the American chemical abstracts system from the years 1967-1992, carried out by the Gmelin Institute (Staffordshire, UK). Table 1 shows properties of silicon nitride.

Properties of Silicon Nitride

In 1970’s Alumina (Al2O3) and zirconia (ZrO2) ceramic introduced in orthopedic for replacement of hip and knee instead of CoCr because of less wear than metal surface [7-9]. Silicon nitride is non-oxide ceramic and has shown properties compatible for orthopedic surgery, various literature have presented suitability of silicon nitride for hip/knee joint replacement. It is biocompatible along with having higher strength and toughness [10,11]. Silicon nitride has two principle modes of wear: mechanical and tribo-chemical.the mechanical mode of wear observes at high load, low speed and start-stop conditions. While, the tribo-chemical wear occurs during dissolution of silicon nitride in lubricating environment. In tribo-chemical wear hydrated silicon oxide layer forms between articulating surfaces and it occurs during low load, low speed, and continue motion. Wear testing of silicon nitride in presence of water based lubrication shown very low coefficient of friction and low wear rate [12]. The wear of silicon nitride in water mainly occurs due to tribochemical dissolution without release of any solid wear particles. Sliding wear of silicon nitride against silicon nitride in presence of water releases silica. Some of investigations have reported that released silica degrades in Phosphate Buffered Saline (PBS) and that Si ions can be incorporated into bone tissue [13,14]. Boshiitskaya et al. [15] in their work presented that silicon nitride dissolve in blood serum, gastric juice and a synthetic biochemical media at pH 7.4., suggesting that silicon nitride is biocompatible and biodegradable along with compatible wear rate. Johanna Olofsson et al. [16] evaluated the wear performance of silicon nitride against silicon nitride in presence of PBS and bovine serum, test result showed comparative wear rate than other wear pairs and formation of tribo-film on surface controlling friction and wear.

Any material used in orthopedic application must be bio inert. Silicon nitride along with its superior mechanical properties it is biocompatible. Kue et al. [17] assessed biocompatibility if silicon nitride in vitro model using human osteoblast- like MG- 63 cell lines. They concluded that silicon nitride is a non-toxic, biocompatible ceramic for propagation of functional human cells in vitro. Guedes et al. [18] used silicon nitride implant in rabbit tibias for 8 week and found no adverse reaction, with bone in growth into and around the implants.

Orthopedic Applications of Silicon Nitride

Silicon nitride is extensively used in orthopedic bearings since from decades, because of its low wear rate and low coefficient of friction than cobalt-chrome metal bearing. Compared to oxide ceramic used in orthopedic, silicon nitride has unique property to be formulated into a porous substrate as well as a hard glassy bearing surface. As a porous material, it is capable of bone in growth. Total joint replacement, like prosthetic hip and knee replacement requires material with low wear rate and low frictional coefficients. Silicon nitride sliding against itself, or metal, or polyethylene becomes ultrasmooth due to tribochemical polishing, and friction becomes very low at increasing sliding distance [19]. Thus silicon nitride is very favorable for hip/knee joint replacement, considering its tribological properties when articulating against itself in water. Silicon nitride is radiolucent, so that both the implant and the underlying bone can be visualized on plain radiography, which is not possible with metal implants.

Conclusion

Silicon nitride has favorable properties, presenting its potential for use in the biomedical field expecting biocompatibility, strength, and endurance. With rise in number of joint replacement surgeries demand for material with high strength increased, so that life expectancy of joint can be improved. Silicon nitride with its mechanical properties and biocompatibility will play major role in joint replacement surgeries.

References

- Reffitt DM, Ogston N, Jugdaohsingh R, Cheung HFJ, Evans BAJ, et al. (2003) Orthosilicic acid stimulates collagen type 1 synthesis and osteoblastic differentiation in human osteoblast-like cells in vitro. Bone 32(2): 127-135.

- Jugdaohsingh R (2007) Silicon and Bone Health. J Nutr Health Aging 11(2): 99-110.

- Jurkic LM, Cepanec I, Pavelic SK, Pavelic K (2013) Biological and therapeutic effects of ortho-silicic acid and some ortho-silicic acidreleasing compounds: new perspectives for therapy. Nutr Metab (Lond) 10(1): 2.

- Riley FL (2000) Silicon nitride and related materials. J Am Ceram Soc 83(2): 245-265.

- Poper P (1994) Applications of Silicon Nitride. Key Eng Mater 89- 91:719.

- Zoran K, Vladimir DK (2012) Silicon nitride: the engineering material of the future. J Mater Sci 47(2): 535-552.

- Tsukamoto R, Chen S, Shoji H, Clarke IC, Asano T, et al. (2005) Improved wear performance with crosslinked UHMWPE and zirconia implants in knee simulation. Acta Orthop 77(3): 505-511.

- Williams S, Butterfield M, Stewart T, Ingham E, Stone M, et al. (2003) Wear and deformation of ceramic-on-polyethylene total hip replacements with joint laxity and swing phase microseparation. Proc Inst Mech Eng H 217(2): 147-153.

- Takahashi Y, Sugano N, Zhu W, Nishii T, Sakai T, et al. (2012) Wear degradation of long-term in vivo exposed alumina-onalumina hip joints: linking nanometer-scale phenomena to macroscopic joint design. J Mater Sci Mater Med 23(2): 591-603.

- Bal BS, Khandkar A, Lakshminarayanan R, Clarke I, Hoffman AA, et al. (2009) Fabrication and testing of silicon nitride bearings in total hip arthroplasty: winner of the 2007 “HAP” PAUL Award. J Arthroplasty 24(1): 110-116.

- Neumann A, Unkel C, Werry C, Herborn CU, Maier HR, et al. (2006) Prototype of a silicon nitride ceramic-based miniplate osteofixation system for the midface. Otolaryngol Head Neck Surg 134(6): 923- 930.

- Xu J, Kato K (2000) Formation of tribochemical layer of ceramics sliding in water and its role for low friction. Wear 245(1-2): 61-75.

- He Q, Shi J, Zhu M, Chen Y, Chen F (2010) The three-stage in vitro degradation behavior of mesoporous silica in simulated body fluid. Microporous Mesoporous Mater 131(1-3): 314-320.

- Boanini E, Gazzano M, Bigi A (2010) Ionic substitutions in calcium phosphates synthesized at low temperature. Acta Biomater 6(6): 1882-1894.

- Boshitskaya NV, Bartnitskaya TS, Makarenko GN, Lavrenkko VA, Danilenko NM, et al. (1996) Theory, synthesis technology, properties of powders and fibers, Chemical stability of silicon nitride powders in biochemical media. Powder Metallurgy and Metal Ceramics 35(9-10): 497-500.

- Johanna O, Mikael TG, Torun B, Cecilia P, Staffan J, et al. (2012) Evaluation of silicon nitride as a wear resistant and resorbable alternative for total hip joint replacement. Biomatter 2(2): 94-102.

- Kue R, Sohrabi A, Nagle D, Frondoza C, Hungerford D, et al. (1999) Enhanced proliferation and osteocalcin production by human osteoblast-like MG63 cells on silicon nitride ceramic discs. Biomaterials 20(13): 1195-1201.

- Guedes ESCC, König JrB, Carbonari MJ, Yoshimoto M, AllegriniJr S, et al. (2008) Tissue response around silicon nitride implants in rabbits. Journal of Biomedical Materials Research- Part A 84(2): 337-343.

- Mazzocchi M, Bellosi A (2008) On the possibility of silicon nitride as a ceramic for structural orthopaedic implants. Part I: Processing, microstructure, mechanical properties, cytotoxicity. Journal of Materials Science: Materials in Medicine 19(8): 2881-2887.