Comparative Study between Nanoparticles Incorporated with Magnetite added in Concrete for Civil Construction

Theodoro da Rosa Salles1,2, Franciane Batista Nunes1,2, Amanda Carolina Pimentel1, Franciele da Silva Bruckmann1,2, Ivana Zanella da Silva1; Cláudia Lange dos Santos1 and Cristiano Rodrigo Bohn Rhoden1,2*

1Postgraduate Program in Nano sciences, Franciscan University, Brazil

2Department of Nanostructured Magnetic Materials - LaMMaN, Franciscan University, Brazil

Submission: July 07, 2022; Published: July 27, 2022

*Corresponding Author: Cristiano Rodrigo Bohn Rhoden, Postgraduate Program in Nano sciences & Department of Nanostructured Magnetic Materials - LaMMaN, Franciscan University -UFN, Brazil

How to cite this article:Theodoro d R S, Franciane B N, Amanda C P, Franciele d S B, Ivana Z da S, et al. Comparative Study between Nanoparticles Incorporated with Magnetite added in Concrete for Civil Construction.Civil Eng Res J. 2022; 13(1): 555855. DOI 10.19080/CERJ.2022.13.555855

Abstract

Civil construction considerably developed in the last years and technology has become an ally in the quality improvement of the materials, mixtures and structures. Reinforced concrete, the main construction method employed, admits variations in properties and strengths according to the composition and additives adopted, aiming to meet project specifications. Increasingly, nanotechnology has been inserted as an application for the engineering to improve properties such as the porosity and mechanical resistance, mainly due to characteristics of high surface area and nanometric dimension. This study evaluates the effect of added magnetite derivative nanoparticles in the concrete for comparative purposes of mechanical strength. In this context, graphene oxide (GO) and nanosilica (NS) were synthesized and, together with graphite nanosheets (GR) and nanocellulose (NC), incorporated with magnetite (Fe3O4) in the proportions 1:5 and 1:10 (in mass: mass ratio) (Figure 1). The nanoparticles were characterized by the methods XRD and FTIR. When added in concrete, in the 0.03% proportion by weight of the cement according to the referring regulations, tests of workability (Slump Test) and resistance to the compressive forces were carried out. The Slump Test demonstrates that the mixture remained workable in acceptable way in all samples. The compression test showed that NC incorporated with magnetite reduced the mechanic resistance by up to 11% when compared to the reference, while GR magnetite incorporated in the proportion 1:5 increase the resistance values in 8%, as well as the  in a 1:10 proportion, also resulted in significant increases.

in a 1:10 proportion, also resulted in significant increases.

Keywords: Engineering; Cement; Resistance increase; Nanoparticles

Introduction

The environment of civil construction mobilizes several sectors of material supply, production, commercialization, and manpower. Pastes used in civil works have a common component, Portland cement, which, added to the aggregates, additives, and water from the concrete; When combined with steel bars it gives rise to reinforced concrete. Among structural design options, reinforced concrete is the most used arrangement in Brazil [1]. Different compounds have been included in reinforced concrete aimed to improve their basic properties, such as workability and durability. In addition, another important property that can be enhanced is mechanical resistance, considering that an increase in strength can reduce steel consumption as well as construction costs [2]. Thus, nanoscience and nanotechnology are useful tools for the synthesis and modification of compounds in order to produce stronger, more flexible, and stable materials [3,4].

Additionally, nanocomposites are promising materials, as the combination of two or more compounds can reduce the individual limitations [5]. At the same time, magnetic nanocomposites have potential application in civil construction due to the compatibility and expansion after the formation of cracks, filling the empty spaces [6]. It is well reported that the mechanical resistance of concrete, an important parameter for civil construction, can be improved with the use of carbon nanomaterials, nanosilica, titanium dioxide, iron oxide, calcium hydroxide, and zeolite [7]. This increase is mainly related due to effective pore filling of the material, considering the nanometric dimension of the NPs [8]. Graphene oxide (GO) is an oxidized product of graphite formed by a honeycomb-like carbonic network with numerous oxygenated functional groups on the surface. This nanomaterial presents potential properties for addition to concrete that makes it possible to improve the characteristics (mechanical resistance and durability) [9,10]. Recently, studies reported that the GO may increase 33% and 58% the compressive resistance and cement paste bending, respectively. This increases concerns about the interaction between the empty spaces (concrete) and GO, hydration reaction, as well as a strong bond with carboxylic groups [11]. The addition of graphite nanosheets and carbon nanofibers in high-performance concrete resulted in an increase of 187% in absorption capacity, 56% in tensile resistance in compression, 59% in flexural tensile strength, and 276% in tenacity, using 0.3% of nanoparticles [12]. Tabatabaei [13] reported that the production of graphite nanosheets emits 80% less CO2 than cement. At the same time, the incorporation of 5% nanoparticles in material can reduce the effects of global warming by 21%. Another material with the potential to replace the amount of cement is nanosilica due to its low cost and sustainable source. This nanoparticle reacts with calcium hydroxide during the hydration of Portland cement, not only increasing the resistance and pore reduction but also decreasing the pH, which is related to the protection of reinforcement against corrosion. Therefore, this process densifies the microstructures, reducing the rate of entry of water and chloride ions [14]. The incorporation of polymeric nanoparticles into cement can also improve corrosion resistance and decrease permeability and thermal conductivity. Studies revealed that nanocellulose can alter the fracture behavior of cement pastes. By adding 0.2% and 1.0% of cellulose nanocrystals to the cement, the compressive strength increased by 10% and 17%, respectively. These results can be explained by the surface area of the nanoparticle as well as the transfer of tension with cement components [15]. Considering that only few studies reported the use of nanoparticles in reinforced concrete, this work aimed to investigate the influence of the incorporation of nanoparticles and magnetic nanocomposites (NC⋅Fe3O4, NS⋅Fe3O4,GR⋅Fe3O4 and GO⋅Fe3O4) and the effect of the amount of magnetite in composite material on the mechanical resistance.

Methodology

Synthesis and characterization of Magnetite Incorporated Nanoparticles

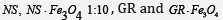

The graphite and nanocellulose were purchased commercially

from Sigma-Aldrich and Delaware, respectively. The graphene

oxide and nanosilica was synthesized at Laboratório de Materiais

Magnéticos Nanoestruturados (LaMMaN). (Table 1) shows the

informations of nanomaterials and magnetite incorporation

proportions. Graphene oxide (GO) was synthesized according to

Salles et al. [10]. Graphite in flakes (1 g) (Sigma-Aldrich ®) and

60 mL of 98% H2SO4 (Synth ®) were added in an erlenmeyer,

under magnetic stirring (120 rpm). The mixture remained under

stirring for 20 minutes at room temperature. 6 g of KMnO4 (Synth

®) was slowly added over 10 minutes. Sequentially, the reaction

was heated to 40 °C and kept under stirring for 5 h. After this

time, 180 of distilled water was added in the reaction and kept

under stirring for 10 h at room temperature. Finally, the solution

was heated at 40 °C for 1 h and added 300 mL of distilled water

and 10 mL of H2O2 35% (Synth ®) to reduced Mn (VII) species.

The product was washed consecutives times with distilled

water and dried at 50 °C. The nanosilica synthesis was carried

out according to Ong et al. [16]. The process was separated into

three steps: acid leaching, calcination, and top-down process to

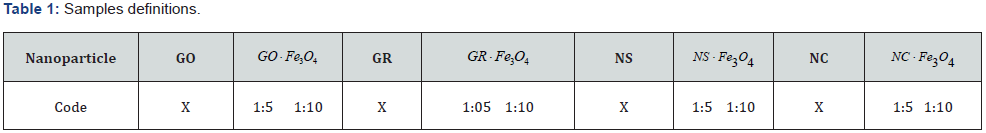

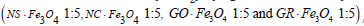

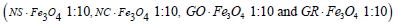

reduce particle size. The incorporation of magnetite into (NS, NC,

GO, and GR) were accomplished according to the methodology

described by Rhoden et al. [17]. In a 250 mL round-bottom flask

containing 100 mL of ultrapure water previously deoxygenated, 100 mg of (NS, NC, GO, and GR) were added singly with different

amounts of iron chloride II (FeCl2) (Sigma-Aldrich ®) i.e., 500

mg for  , 1000

mg for

, 1000

mg for  . Then, the pH of the middle was adjusted for (pH ≈ 9.0), with

ammonium hydroxide (Synth ®) allowing the creation of oxidant

middle, favoring the iron incorporation. Afterward, the mixture

was submitted alternately to ultrasonic irradiation (Elma, power

150W) and heating (50 °C) for 180 minutes. When the sample

showed magnetic field responsiveness, the solution was poured

with the assistance of acetone (Synth ®). Lastly, the material was

dried in an oven (DeLeo) at 50 °C for total evaporation of the

solvent.

. Then, the pH of the middle was adjusted for (pH ≈ 9.0), with

ammonium hydroxide (Synth ®) allowing the creation of oxidant

middle, favoring the iron incorporation. Afterward, the mixture

was submitted alternately to ultrasonic irradiation (Elma, power

150W) and heating (50 °C) for 180 minutes. When the sample

showed magnetic field responsiveness, the solution was poured

with the assistance of acetone (Synth ®). Lastly, the material was

dried in an oven (DeLeo) at 50 °C for total evaporation of the

solvent.

Concrete Assay

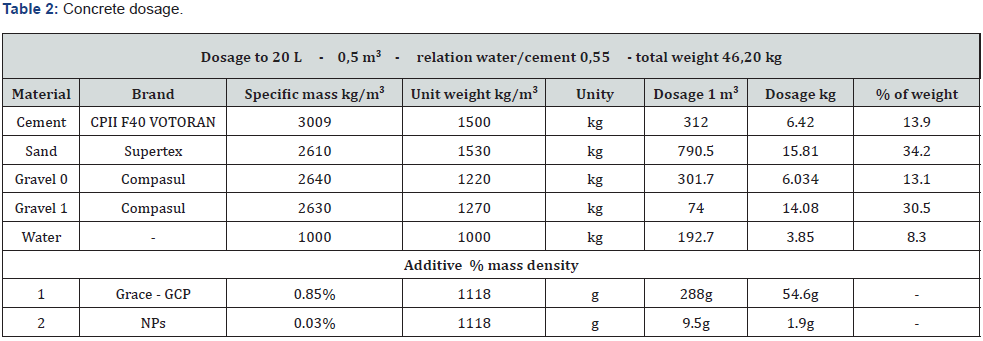

(Table 2) shows the proportions and information which were used to release to experiments (compress tensile strength and slump teste). The specifications: Cement Portland II with filler addition II (CP II F) Votoran; water treated to Water Treatment Plants of region; sand with dimension of 1.2 mm. Gravel 0 (between 4.9 and 9.5 mm); Gravel 1 (between 9.5 and 19 mm); multifunctional additive Grace (GCP); nanoparticles describe in (Table 1). The concrete dosage was employed by Brazilian Regulation [18]. For the experiments with nanoparticles, 0.03% (mass related) of NPS in cement. According to the literature, increments higher than 3% result in more resistance. However, non-represent compensatory gain, and with this value the nanoparticles can agglomerate, harming the filling of cracks [11].

Workability Assay - Slump Test

The conical slump test was completed as per Brazilian Standard [19,20], i.e., 20 cm in the base and 10 cm in the top with 30 cm the total height of the cylinder. The cylinder was filled with the sample, the top of the cylinder was smoothed over, and the cylinder lifted slowly and evenly. The change in height between the cylinder and deformed material was measured. The midpoint of the slumped material was taken as the representative height. Heights were measured with a ruler to the nearest 0.5 mm [21].

Simple axial compressive strength test

The simple axial compressive strength test was accomplished according to Brazilian Regulations [22], and consists of compressing a specimen, generating a linear deformation. The specimen was introduced in cylindrical models of 10 cm of diameter and 20 cm of height, according to Brazilian Regulations [23,24], and used a press (EMIC) of 2000 kN.

Results and Discussion

Synthesis of nanoparticles with different amount of magnetite

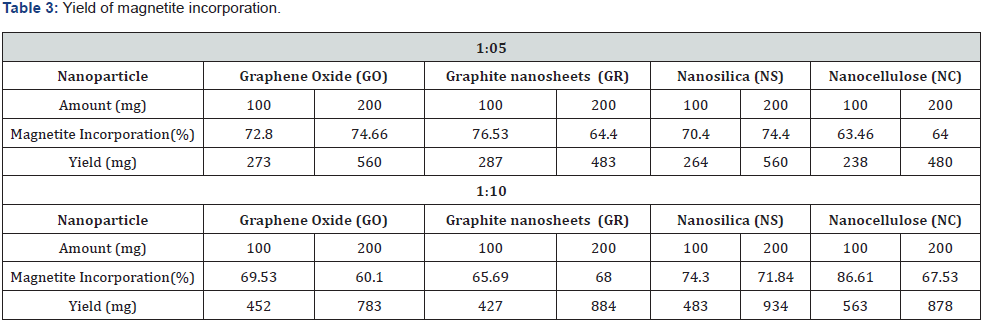

The yields of magnetite incorporation are shown in (Table 3) For the process 100 and 200 mg of nanomaterials (GO, GR, NS, and NC) were employed, and obtained 70% of average yield. This results, agree with Rhoden et al. [17] that synthesized GO with different amounts of magnetite incorporated, using a similar method. The methodology employed for magnetization proved to be highly efficient, with good yields, low energy requirements, and a reduced time process.

X-ray diffraction

The XRD of nanomaterials (GO, GR, NS, NC, and nanocomposites with different amounts of incorporated magnetite) are shown in (Figure 2). For graphene oxide (Figure 2a), it is possible to observe a signal at 2Ɵ ≈ 11.10° (001), characteristic of GO [25].

The XRD of graphite nanosheets (Figure 2b) peaks around 2Ɵ ≈ 26.4° (002) and 54° (004), attributes of graphite [26]. The XRD pattern of nanosilica shows a broad peak around 2Ɵ ≈ 22° (100), corresponding to an amorphous structure [27]. In the nanocellulose (NC), peaks at 2θ≈14.7°, 16.4°, 22.5°, and 34.2° were assigned to the (11 ̅0), (110), (002), and (040) planes respectively, presenting the typical diffraction of nanocellulose [28]. For magnetic nanomaterials, the appearance of signals at 2Ɵ ≈ 30.2, 35.3, 43.5, 57.10, and 63.3°, corresponding to the indices (220), (311), (400), (511), and (440), which are compatible with magnetite (JCPDS card no. 19-0629). However, the peaks of GO and NS in GO⋅ Fe3O4 1:5, GO⋅ Fe3O4 1:10, NS ⋅ Fe3O4 1:5 and NS ⋅ Fe3O4 1:10 ,are constrained due to the large amount of Fe3O4, indicating the recovery of nanomaterials surfaces and agglomerate of magnetite [5,17]. For NC ⋅ Fe3O4 1:5 and NC ⋅ Fe3O4 1:10, the presence of peak (002) and disappearance of others inferred a decrease in the crystallinity of the polymer, which may result from the magnetization process.

FTIR

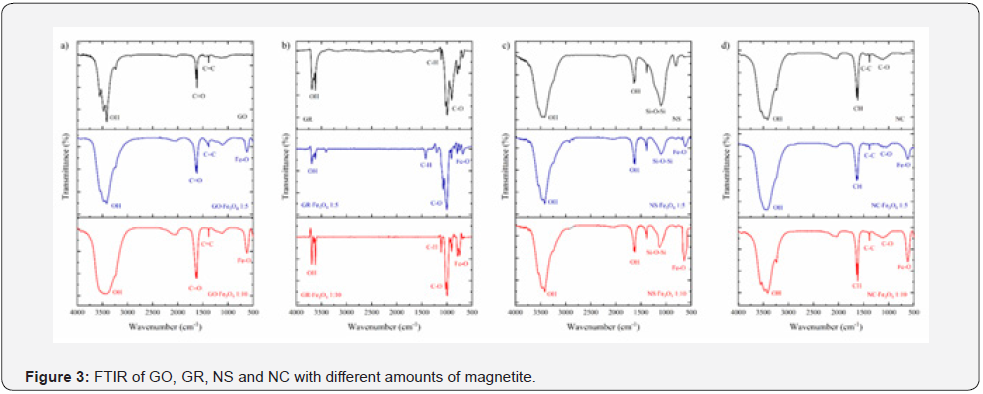

(Figure 3) shows the FTIRs spectrums of nanomaterials. For graphene oxide (Figure 3a), an intense band in 3400 cm-1 refers to the axial deformation of the hydroxyl group, showing the presence of OH on the nanomaterial’s surfaces. The signals at 1497 and 1452 cm-1 correspond to C=O and C=C groups, respectively [10]. (Figure 3b), indicates a water absorption peak at 3460 cm-1 of graphite nanosheets, and around 1500 and 1000 cm-1, corresponding to C-H and C-O groups [29]. According to (Figure 2c) (NS FTIR spectrum),the peaks at 801 and 474 cm-1 indicate the symmetrical Si-O-Si, and 1011 cm-1 to the asymmetric vibration of Si-O [30]. (Figure 2d) shows the spectrum of NCs, it is possible to observe around 3486 cm-1 the band related to vibrational stretching of OH bond, and 1600 cm-1 indicates the water absorption by NC molecules. Moreover, at 1400, 1100, and 1050 cm-1, are attributed to CH, C-C, and C-O stretching, and Calquil-O, respectively [31]. For magnetic nanomaterials, the appearance of a peak at 600 cm-1 infers the presence of Fe-O stretching, which originated from magnetite [17].

Compress tensile strength

The cylindrical standard used for compressing tensile

experiments was measured in two different directions,

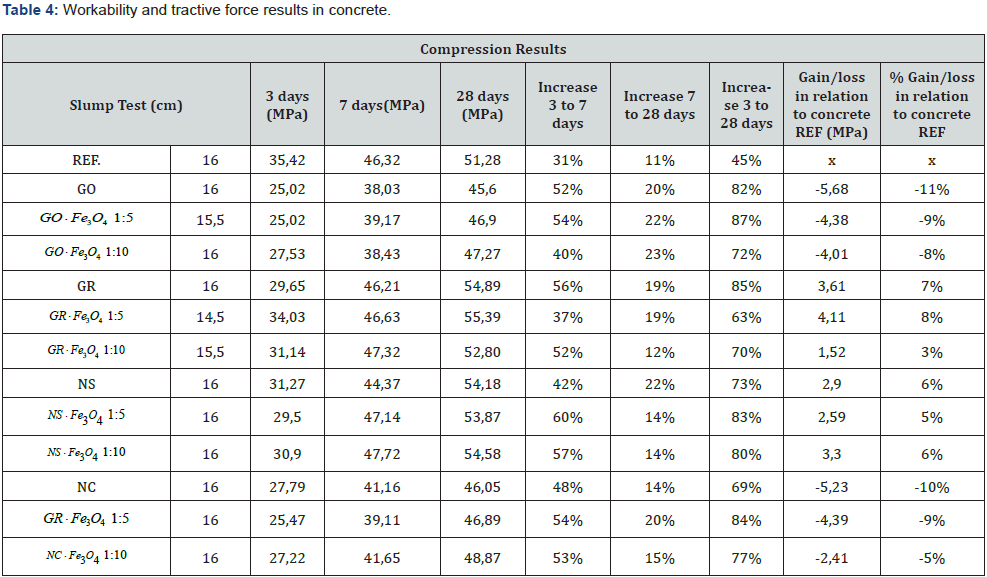

obtaining 9.94 and 10.25 cm. (Table 4) and (Figure 4) show the results of compress tensile strength. For 3 days, none

of the samples with nanoparticles obtained higher results

than REF (35.42 MPa). The  presented 34.03 MPa.

However, GO and

presented 34.03 MPa.

However, GO and  showed the lowest strength values, 25.05 MPa for both nanomaterials. On the other hand,

it is possible to observe an increase in compression resistance

with higher amount of employed iron in the magnetization process. At 7 days, the REF broke at 46.32 MPa, overcome by

NS ⋅ Fe3O4 1:10 (47.72MPa), GR⋅ Fe3O4 1:5 (46.63 MPa) and GR⋅ Fe3O4 1:5 (47.32 MPa) .

showed the lowest strength values, 25.05 MPa for both nanomaterials. On the other hand,

it is possible to observe an increase in compression resistance

with higher amount of employed iron in the magnetization process. At 7 days, the REF broke at 46.32 MPa, overcome by

NS ⋅ Fe3O4 1:10 (47.72MPa), GR⋅ Fe3O4 1:5 (46.63 MPa) and GR⋅ Fe3O4 1:5 (47.32 MPa) .

Thereafter 28 days, the REF reached 51.28 MPa, which was taken by GR, GR⋅ Fe3O4 1:5, GR⋅ Fe3O4 1:10, NS, NS ⋅ Fe3O4 1:5, NS ⋅ Fe3O4 1:10 , presenting 54.89, 55.39, 52,80, 54.18, 53.87 and 54.58, respectively. However, GO, NC, and their nanocomposites with different amounts of magnetite incorporated do not overcome the compress results found by the REF sample. The increase in resistance is related to the more effective filling of interstices by the mixture of nanoparticles (nanomaterials and magnetic nanoparticles) in the concrete. Along with this, it is possible to observe that with increasing in magnetite incorporation the samples present more resistance when compared to REF. On the other hand, GO, NC and their nanocomposites, present low values than REF, probably to the pore dispersion of nanoparticles along the cylindrical scaffold [32,33,34].

Conclusion

This study aimed experimentally evaluate the effects of the addition of magnetite incorporated nanoparticles in graphene oxide, graphite nanosheets, nanosilica and nanocellulose, in construction cement, in order to compare their performance in relation to the mechanical properties of concrete, a mixture used in the main constructive method for civil engineering buildings. The nanoparticles were characterized by the methods of X-ray Diffraction (XRD) and Fourier-transform Infrared Spectroscopy (FTIR). By comparing the nanoparticles added in concrete with a referential sample (without NPs). The study reveals that all analyzed material maintained the workability, reducing around 10%, remaining in accordance with the tecnical regulation. The Slump test revealed that only the samples containing GO and NC decrease the compression resistance, although no significant workability reduction was observed. The graphite nanosheets and nanosilica, with and without incorporated magnetite, showed increasing resistance in concrete by about 8% compared to the reference by 28 days test. These results are mainly related to the interactions of the NPs and water dispersion fulfilling the cement pores due its nanometric dimensions. Considering the initial results regarding the increase in the concrete resistance with the conservation of the workability, the addition of the nanoparticles arises the possibility of further studies from application NPs in civil construction, improving the relation of water/cement/iron, aiming conservancy and costs reduction without environmental damage and quality maintenance.

References

- (1994) ABNT. NBR 7222:2011 Mortar and concrete - Determination of tensile strength by diametrical compression of cylindrical specimens. Rio de Janeiro, Brazil.

- Assaggaf RA, Ali MR, Al-Dulaijan SU, Maslehuddin M (2021) Properties of concrete with untreated and treated crumb rubber - A review. J Mat Res Technol 11: 1753-1798.

- Nasrollahzadeh M, Sajadi SM, Sajjadi M, Issaabadi Z (2019) An Introduction to Nanotechnology. In Interface Science and Technology p: 1-27.

- Nunes FB, Salles TR, Vincensi EC, Vargas GO, Vidal LZ, et al. (2021) Easy and fast obtaining of magnetic graphite. Discip Sci Cienc Nat Technol 22(3): 45-52.

- Bruckmann FS, Rossato Viana A, Tonel MZ, Fagan SB, Garcia WJS, et al. (2022) Influence of magnetite incorporation into chitosan on the adsorption of the methotrexate and in vitro cytotoxicity. Environmental Science and Pollution Research International.

- Seifan M, Ebrahiminezhad A, Ghasemi Y, Samani AK, Berenjian A (2018) The role of magnetic iron oxide nanoparticles in the bacterially induced calcium carbonate precipitation. Appl Microbiol Biotechnol 102(8): 3595-3606.

- Eivazzadeh-Keihan R, Maleki A, de la Guardia M, Bani MS, Chenab KK, et al. (2019) Carbon based nanomaterials for tissue engineering of bone: Building new bone on small black scaffolds: A review. J Advan Res 18: 185-201.

- Sanchez F, Sobolev K (2010) Nanotechnology in concrete - A review Construction and Building Materials 24(11): 2060-2071.

- Xu G, Shi X (2018) Graphene oxide-modified pervious concrete with fly ash as the sole binder. ACI Mater J 115(3).

- Salles TR, Rodrigues HB, Bruckmann FS, Alves LCS, Mortari SR, Rhoden CRB (2020) Graphene oxide optimization synthesis for application on laboratory of Universidade Franciscana. Discip Sci Ser Cienc Tecnol 21(3): 15-26.

- Wu YY, Que L, Cui Z, Lambert P (2019) Physical properties of concrete containing graphene oxide nanosheets. Materials 12(10): 1707.

- Meng W, Khayat KH (2016) Mechanical properties of ultra-high-performance concrete enhanced with graphite nanoplatelets and carbon nanofibers. Compos B Eng 107: 113-122.

- Tabatabaei M, Dahi Taleghani A, Alem N (2020) Surface-modified graphite nanoplatelets to enhance cement sheath durability. SPE Drilling & Completion 35(03): 452-464.

- Du H, Du S, Liu X (2014) Durability performances of concrete with nano-silica. Constr Build Mater 73: 705-712.

- Ghahari S, Assi LN, Alsalman A, Alyamaç KE (2020) Fracture properties evaluation of cellulose nanocrystals cement paste. Materials 13(11): 2507.

- Ong RH, Mohd Eqhwan Iskandar W, Maksudur Rahman Khan M (2020) Rice husk nanosilica preparation and its potential application as nanofluids. In Engineered Nanomaterials - Health and Safety. IntechOpen.

- Rhoden CRB, Bruckmann FS, Salles TR, Kaufmann Junior CG, Mortari SR (2021) Study from the influence of magnetite onto removal of hydrochlorothiazide from aqueous solutions applying magnetic graphene oxide. J Water Process Eng 43(102262): 102262.

- (2018) ABNT NBR 16697:2018 Portland Cement - Requirements.

- (1998) ABNT. NBR NM 67: 1998 Concrete-Determining consistency by lowering the truncated cone.

- Hooton RD, Ferraris CF, de Larrard F (1998) Modified slump test to measure rheological parameters of fresh concrete. Cem, Concr Aggreg 20(2): 241.

- Clayton S, Grice TG, Boger DV, (2003). Analysis of the slump test for on-site yield stress measurement of mineral suspensions. Int J Miner Process 70(1-4): 3-21.

- (1994) ABNTNBR 5738:2015 Molding and curing of cylindrical or prismatic concrete specimens. Rio de Janeiro, Brazil.

- (1998) ABNT NBR NM 33:1998 Concrete-Sampling of fresh concrete. Rio de Janeiro, Brazil.

- (1991) ABNT NBR 12142:2010 Concrete-Determination of flexural tensile strength in prismatic specimens. Rio de Janeiro, Brazil.

- Da Silva Bruckmann F, Mafra Ledur C, Zanella da Silva I, Dotto GL, Rhoden CRB (2022) A DFT theoretical and experimental study about tetracycline adsorption onto magnetic graphene oxide. J Mol Liq 353(118837): 118837.

- Ain QT, Haq SH, Alshammari A, Al-Mutlaq MA, Anjum MN (2019) The systemic effect of PEG-nGO-induced oxidative stress in vivo in a rodent model. Beilstein J Nanotechnol, 10: 901-911.

- Nguyen NT, Nguyen DH, Pham DD, Dang VP, Nguyen QH, et al. (2017) New oligochitosan-nanosilica hybrid materials: preparation and application on chili plants for resistance to anthracnose disease and growth enhancement. Polym J 49(12): 861-869.

- Da Rosa Salles T, da Silva Bruckamann F, Viana AR, Krause LMF, Mortari SR et al. (2022) Magnetic nanocrystalline cellulose: Azithromycin adsorption and in vitro biological activity against melanoma cells. J Polym Environ 30(7): 2695-2713.

- Cheng MM, Huang LJ, Wang YX, Zhao YC, Tang JG, et al. (2019) Synthesis of graphene oxide/polyacrylamide composite membranes for organic dyes/water separation in water purification. J Mat Sci 54(1): 252-264.

- Bruckmann FS, Pimentel AC, Viana AR, Salles TR, Krause LMF, et al. (2020) Synthesis, characterization and cytotoxicity evaluation of magnetic nanosilica in L929 cell line. Discip Sci Ser Cienc Nat Tecnol, 21(3): 01-14.

- Huang S, Zhou L, Li MC, Wu Q, ZhouD, (2017) Cellulose nanocrystals (CNCs) from corn stalk: Activation energy analysis. Materials 10(1): 80.

- Dreyer DR, Todd AD, Bielawski CW, (2014) Harnessing the chemistry of graphene oxide. Chem Soc Rev 43(15): 5288-5301.

- Long WJ, Gu YC, Xing F, Khayat KH, (2018) Microstructure development and mechanism of hardened cement paste incorporating graphene oxide during carbonation. Cemen & Concret Comp 94: 72-84.

- Peyvandi A, Soroushian P, Farhadi N, Balachandra AM, (2018) Evaluation of the reinforcement efficiency of low-cost graphite nanomaterials in high-performance concrete. KSCE J Civ Eng 22(10): 3875-3882.