Influence of Fibers on High Performance Concretes: Fibers Fabricated in Cameroon

Bwemba Charles*, Mbessa Michel and Deodonne Kunwufine

Department of Civil Engineering, NASPW, University of Yaounde 1, Yaounde, Cameroon

Submission: August 26, 2021; Published: September 13, 2021

*Corresponding Author: Bwemba Charles, Department of Civil Engineering, NASPW, University of Yaounde 1, Yaounde, Cameroon

How to cite this article: Bwemba C, Mbessa M, Deodonne K. Influence of Fibers on High Performance Concretes: Fibers Fabricated in Cameroon. Civil Eng Res J. 2021; 12(2): 555833. DOI 10.19080/CERJ.2021.12.555833

Abstract

In this article, steel fibers (sf) and Alcohol polyvinyl fibers (apvf) are used as addition with the aim to obtain high performances concrete (hpc). Some mechanical properties of high performances concrete containing these materials have been studied through bending and compressive tests on prismatic and cylindrical test tubes. The results showed that the addition of fibers in a formulation of high performances concrete gives results that varies from one solicitation to another and from a type of fiber to another:

in the case of the simple compressive strength test, strengths are rather reduced, despite the fact that pieces of test- tube remain sewn after rupture. This is due to the phenomena of multidirectional cracking that appear at the time of the solicitation. The compressive strength decreases more when apvf is used;

ii) concerning the bending test, steel fibers improve considerably the strength and the ductility of concretes thanks to their nature and their geometry. This improvement is favored by the compactness of the matrix;

iii) there is no interest using apvf to improve the ductility or the strength of the hpc in bending. They rather decrease the resistance to the cracking and the rigidity of the material.

Keywords: Steel fibers; Alcohol polyvinyl fiber; Bending; Compressive; Brittle breaking

Introduction

For the last decades, HPC has been subjected to many studies and present exceeding properties and constructability compared to normal concrete [1]. HPC have a brittle behaviour, breaking occurs by fragmentation of the structure resulting from a setting in bending of the “little columns” that would be formed by vertical cracking during loading [2], posing thus a problem of security during work. These studies have led to think of additional components that could improve the compressive strength of HPC, fibers were considered [3-11] since the case of improvement in traction and blending were obvious, fibers would come therefore to sew the “little columns” and prevent their bending. The use of fibers as a waste will also limit the environmental impact [4]. In this work, we use sf and apvf in addition to the hpc to study their influence on some mechanical properties through bending and compression tests on prismatic and cylindrical test-tubes on a specific slag composition of hpc [2].

Materials and Method

Materials

Cements

The cement selected to sufficiently fulfil the role of hydraulic binder in this study is obtained from CIMENCAM (cimenteries du Cameroun). This is a company which produces and sells cements, aggregates and ready to use concretes in Cameroon. Two types of cements have been used: the apc CEM I 52.5 R from Douala and the bfc CEM I 52.5 from Figuil.

Slag

The slag comes from the western region of Cameroon. It can be directly extracted or bought from commercials that extract and sell it in the various local markets of the country.

Superplasticizer

The superplasticizer used in our study is gotten from Sika Cameroon LLC. The superplasticizer is Glénium 51 made with polycarboxylate

Aggregates

The aggregates selected for this study are sand and gravels. The sands are extracted in Monatele which is a town, capital of the Lekie department of the center region of Cameroon. The sand is obtained from river Sanaga. For the gravels, they are extracted from the Nkomtou quarry found at about twenty kilometers north of Yaounde. Two fractions of aggregates have been used: sand (0/4mm) with a density of 2.64 and ground Comblanchien gravel (6/10) with a density of 2.64.

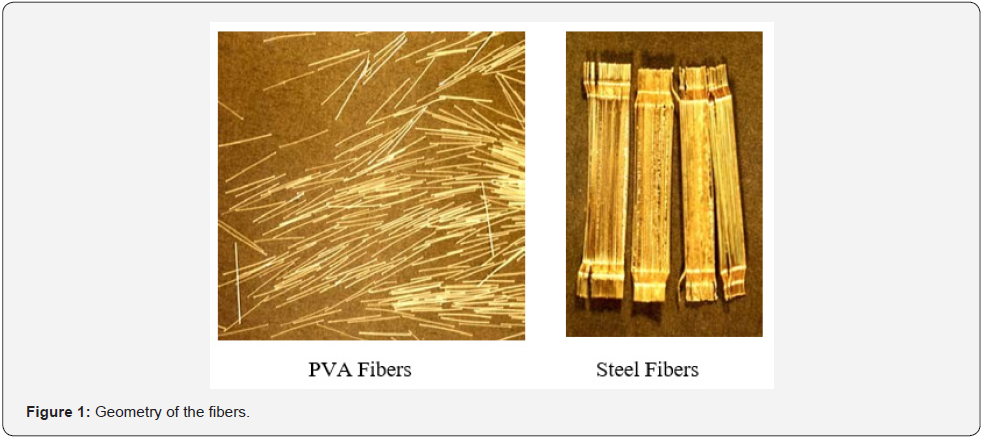

Fibers

Two types of fibers are used: high carbon content sf (RC- 80/30-BP) and polyvinyl alcohol fibres (pvaf) (RF 350). (Figure 1) shows the geometry of the fibers. Their densities are 7.8 for sf and 1.3 for the pvaf. The other properties are presented in annex.

Experimental Methods

Preparation of samples

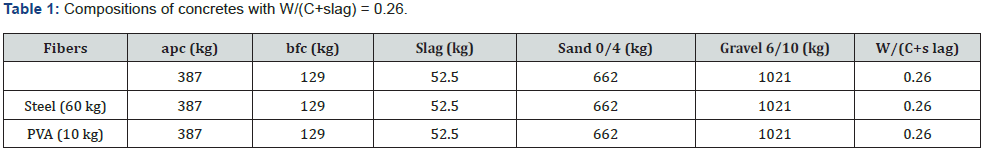

The fibers have been used in addition to a specific slag composition of hpc for its properties [2]. The formulations of concretes are consigned in (Table 1). The dosage of 60 kg/m3 for fibers that we used is a little weaker than the one recommended (annex. 1). Dosage in apvf has been chosen in reference to the one of sf, for a well comparative analysis.

Mixing procedure for the manufacture concrete

Concretes were manufactured as follow:

a. Dry mixing without fibers for 1 minute;

b. Addition of fibers and mixing for 1 minute;

c. Addition of water with Superplasticizer and mixing for 2 minutes;

d. Scraping and mixing for 2 minutes.

The concrete was then collected and sunk in cylindrical 11x22 cm and prismatic 7x7x28 cm molds and vibrated during 10 seconds on a vibrating table. The removal of concrete was realized 24 hours later after placing the concrete molds in lime saturated water.

Compressive strength test

The simple compressive testing has been con- ducted on a 2500 KN capacity press at 28 days after stay in lime saturated water, the cylindrical 11x22 cm test-tubes have been carved previously on a Diamond-tipped millstone machine [2] before being submitted to the simple compression.

Four-point bending test

The configuration of the four points bending test is represented on (Figure 2), it follows the recommendations of the Rilem Technical Committee 49TFR [12]. The test has been achieved on an ADAMEL LHOMARGY press enslaved on a trip with a speed of 1 mm/mn until the first cracking, then with a speed 4 mm/mn. The forces sensor of the press and a displacement sensor situated at the middle of the range under the test-tube (Figure 2) are joined to a tape of measure that allows the acquirement of load-bending deformation curves.

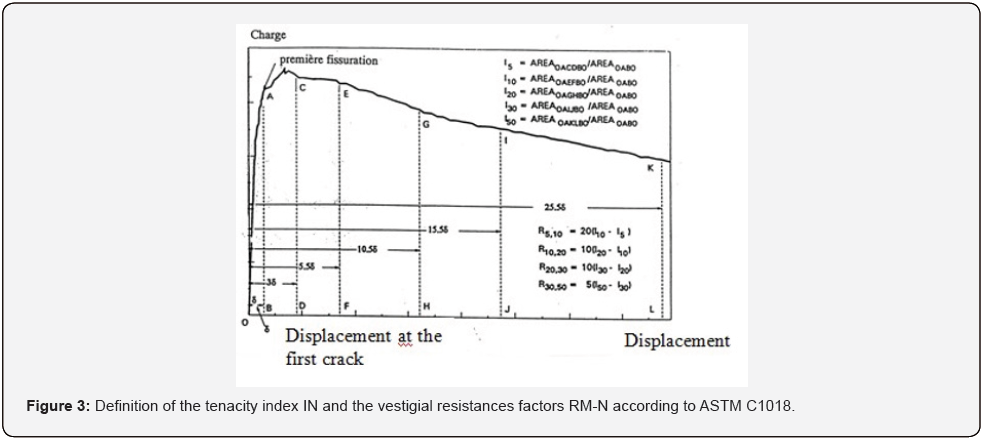

Measuring of the tenacity

In concrete fibers, if fibers are in sufficient quantity, they will permit to reduce the opening of the cracks and to support meaningful loads for bending deformations greater to those corresponding to the first cracking (post-cracking region). This pseudo ductility is often expressed in term of tenacity. The tenacity is the measure of the quantity of necessary energy needed to produce the total breaking of the composite or a given distortion. To characterize it, we used the ASTM method C 1018 [13] in which, the tenacity is defined by the ratio between the energy dissipated until some singular values of the bending deformation and the energy of breaking of the non-reinforced matrix that correspond to the area situated under the load-bending deformation curve until the first cracking. This different ratio, I10, I15, I20, etc..., are called tenacity index (Figure 3). They ex- press themselves as below:

The values of N in these indexes are based on a perfect elastic and mechanical behavior. Thus, for a perfect plastic elastic material, the

Proportionality modulus (LOP) and break modulus (MOR)

(Figure 4) shows the model of the bending deformation curve that can be obtained in four points bending of the fibers concrete. Two zones characterize this curve:

i) A zone of linear elastic behavior until the point of coordinates (fLOP, PLOP) that corresponds to the point of first cracking of the matrix. The maximal constraint equivalent to this load is called proportionality modulus and is noted LOP;

ii) A post-cracking zone of non-linear behavior characterized by a maximal load and its correspond to conventional constraint named break modulus and noted MOR. The value of the bending deformation fMOR in this point characterizes the capacity of deformability of the material under this load.

In this case, according to (Figure 4), the coordinates of the MOR correspond to those of the maximal load. Besides, to better quantify the contribution of the fibers, R report has been calculated:

It characterizes the increase of the resistance due to the addition of the fibers (recovery of load) and is null for the reference concrete (without fibers).

Results and Interpretation

Compressive strength

Water Wells

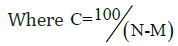

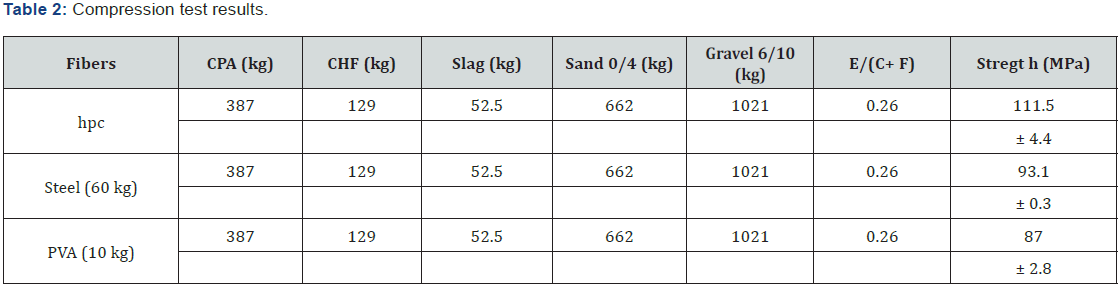

The values obtained from the compressive strength test are in (Table 2). Although Van Gysel could show that the steel fibers increased the resistance in compression of the hpc [15], these results were also confirmed [4, 16 & 17], (Figure 5) shows that additional fibers in the hpc doesn’t improve the resistance in compression [5]: when a created crack (or existing) meets a fiber, it increases, going in the direction of the fiber. The phenomenon intensifies, favored by the multidirectional distribution of the fibers, what led to a premature break of the structure. However, the security is improved relatively and (Figure 6) shows the state of a complete fragmentation on the test-tube, one observes a diagonal macro-cracking for tubs II and III, the two pieces remaining” sewn” by the fibers.

Four points bending test characteristics

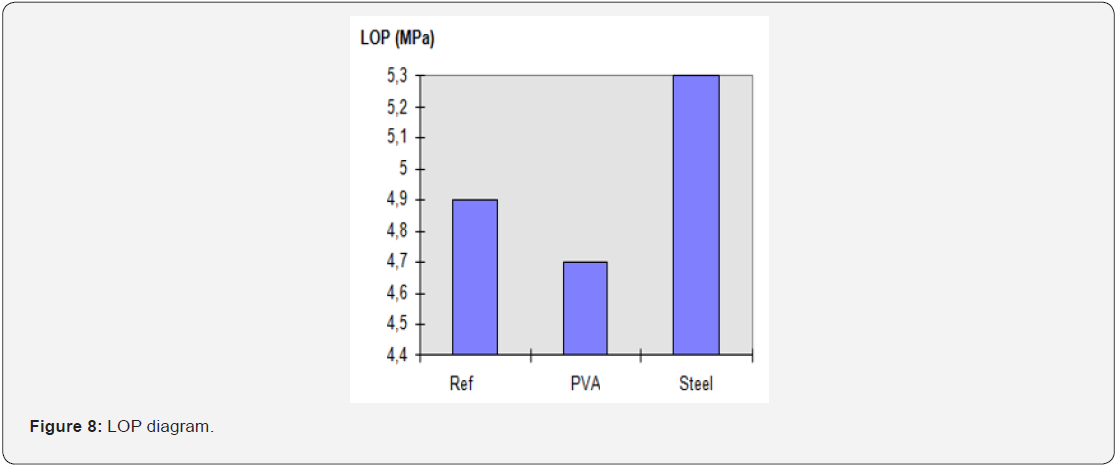

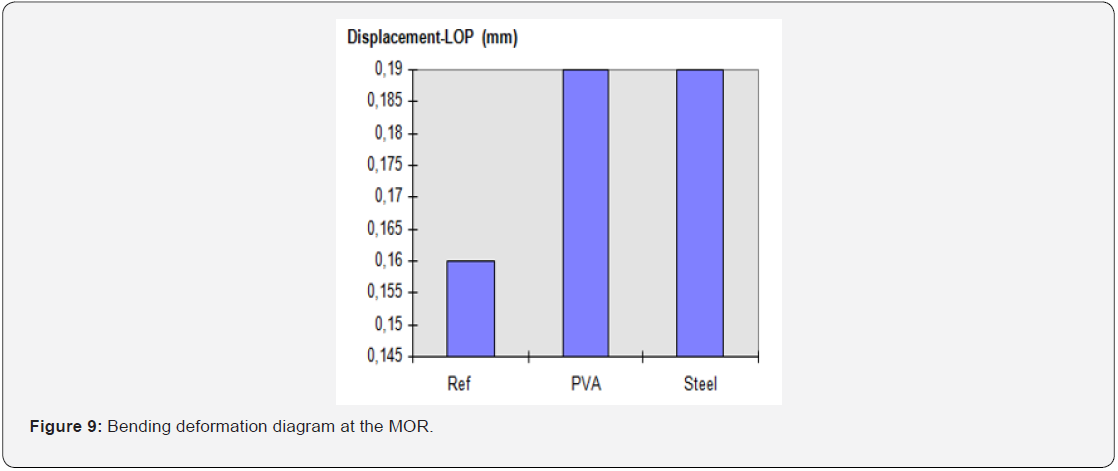

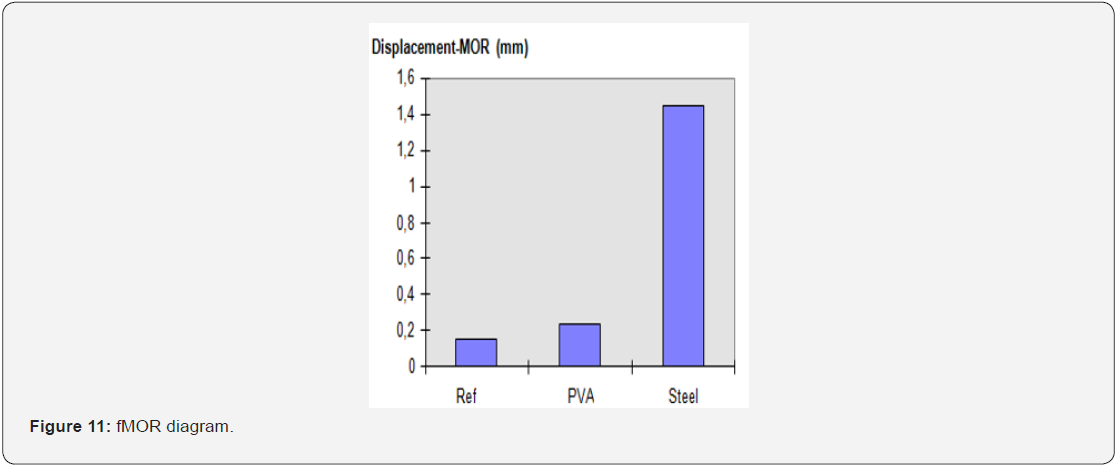

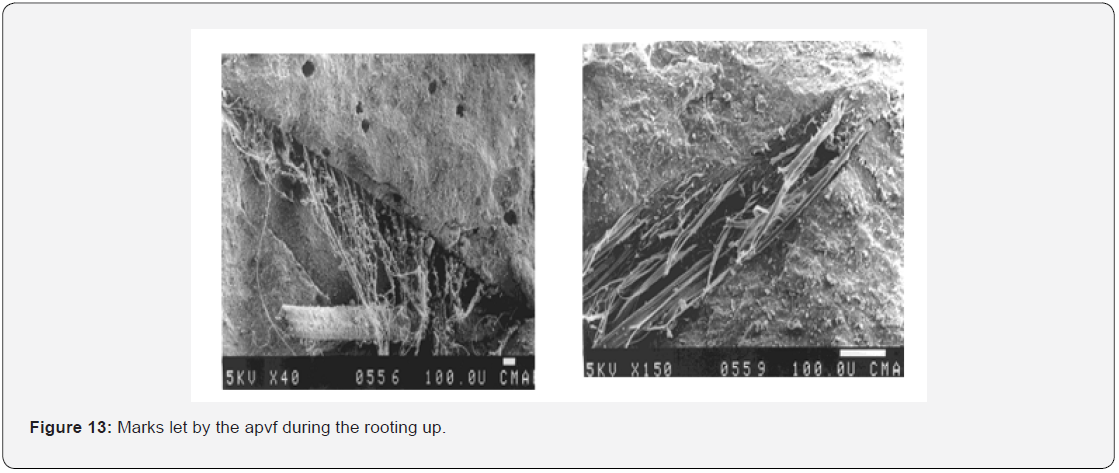

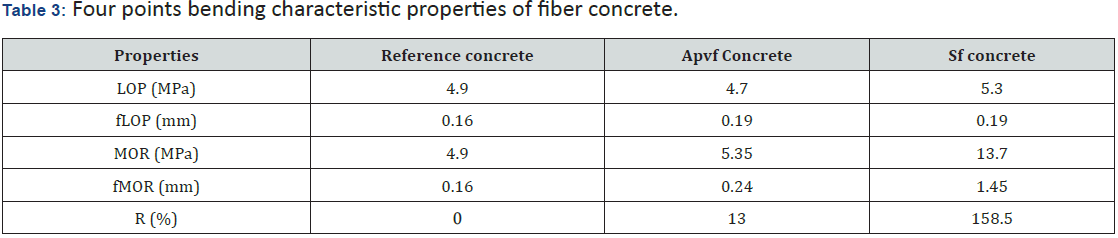

(Figure 7) presents the load-bending deformation test curves. The four points bending test results are consigned in (Table 3), and (Figures 8-12) permit a better appreciation. In the case of the fibers concrete, the results are not surprising, the concrete being elastic brittle, the LOP is overcome to the MOR. (Figure 13) presents the observation with the electronic scanning microscope of the marks let by fibers pulled by fragmentation of the sample, underlining the strong fiber matrix adhesion. Instead of a total rooting up, the fiber tears itself letting glued some its threads on the matrix.

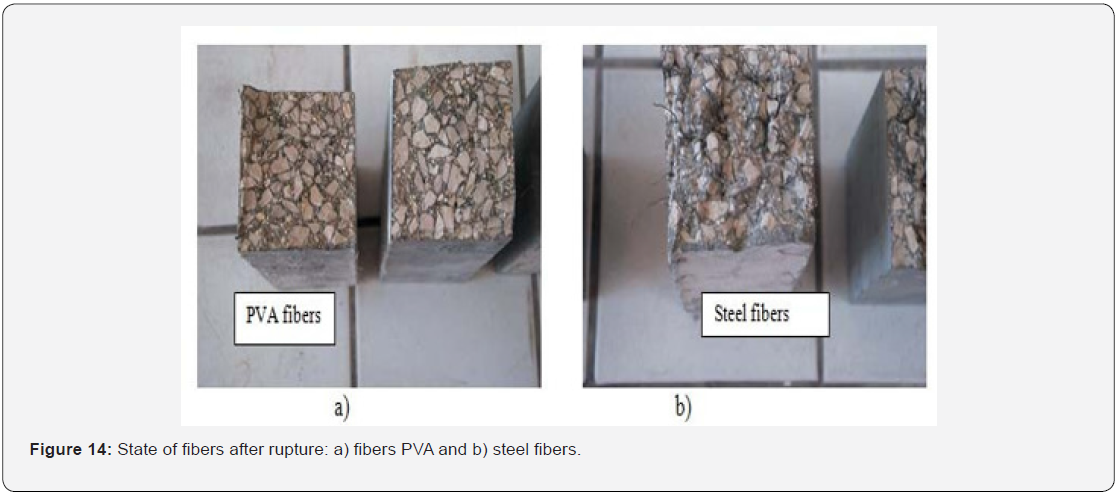

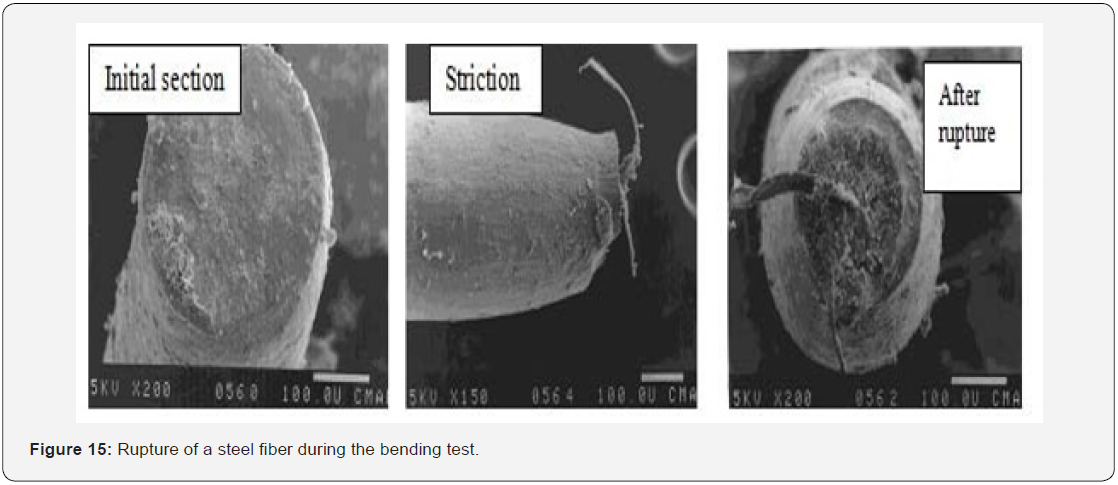

However, the observation of the load-deformation curves (Figure 6) and the results of (Table 3) show that there is no interest to use the apvf to improve the resistance. They rather lower the rigidity and the resistance of the concrete subject to cracking. Their geometry and especially their nature don’t allow a good resumption of load after the first cracking in spite of the very strong fiber-matrix adhesion (very densified): all fibers at the place of the macro cracking are broken after the complete ruin of the structure (Figure 14). The behavior of the concrete stays brittle and, an improvement requires very high dosages making difficult unfortunately the implementation and leading to high costs. The results are rather very satisfactory when one uses sf. The behavior during the elastic phase is identical to the one of the references concretes (without fibers), steel behaves like a very small aggregate. Besides, the resistance during compressive test is increased; the bending deformation and the MOR load increase a lot more. This reveals a good ductility of the material, favored by geometry and the nature of the fibers and the compactness of the matrix [5, 18 & 19]. Indeed, although (Figure 14) presents the steel fibers tips after total break on test- tube characterizing a ruin by slip of the fibers, the observation in the electronic scanning microscope of the sections of the fibers showed that other phenomena take place at the time of the ruin the structure submitted to bending. (Figure 15) presents a relative reduction of sf section characterizing traction break of steel: steel is submitted to traction under the combined effects of the solicitation, the fibers distribution, their geometry, and especially the strong compactness of the matrix and by continuation a strong fibermatrix adhesion.

To the look of the load-deformation curves (Figure 5), three phases have been identified in the bending of this concrete, bound to the nature and the geometry of the fibers:

a) In a first phase, the behavior of the concrete is elastic until the LOP where takes place the first cracking;

b) After cracking, there is a recovery of the load by the fibers. The resistance of the material is going to increase thanks to the strength of fiber-matrix friction. The resistance in traction of the fibers being relatively a lot higher, the strength of friction is going to depend essentially on the fiber-matrix adhesion, the geometry of the fibers, and their length fit- ting in. This resistance increases until the MOR (maximal load);

c) The third and the last phase intervene when some important slips of the fibers begin to occur, due to friction and provoking a detachment of particles of the matrix what drives then to a considerable decrease of the resistance to the ruin of the structure.

Conclusion

The addition of the fibers in a hpc formulation gives results different from a solicitation to another and from a type of fiber to the other:

a. In the case of the simple compression, the resistances are rather decreased, although the pieces of test-tube remain sewn after break, because of phenomena of multidirectional cracking that appear at the time of the solicitation. This decrease of resistance being increased more in the case of the apvf.

b. Concerning bending, sf improves the resistances and the ductility of the concrete considerably thanks to their nature and their geometry. This improvement is favored by the compactness of the matrix.

c. There is no interest to use the apvf to improve the ductility or the strength during bending test of hpc. They rather decrease the resistance to the cracking and the rigidity of the material.

References

- Funk B, Trettin R, Zoz H (2017) From slag to high performance concrete-Manufacturing FuturBeton. Materials Today: Proceedings 4(S2): S81-S86.

- Mbessa M (2011) Roles of ultrafine in high performance industrial concretes. Sl, European University Editions, UK, pp: 139.

- Balendran R, Zhou F, Nadeem A, Leung AY (2002) Influence of steel fibres on strength and ductility of normal and lightweight high strength concrete. Building and Environment 37(12): 1361-1367.

- Iqbal S, Ali A, Holschemacher K, Bier TA (2015) Mechanical properties of steel fiber reinforced high strength lightweight self-compacting concrete (SHLSCC). Construction and Building Materials, 98: 325-333.

- König G, Kützing L (1998) Use of fibers cocktails to increase ductility of high-performance concrete. In: Proceedings of the International Conference on High Performance and Reactive Powder Concrete. Edited by Aïtcin PC, Delagrave Y, Sherbrooke C (eds.) Université de Sherbrooke, Canada, pp. 99-111.

- Vahab AA, Ajimon T (2014) Effect of steel fiber reinforced high performance concrete exterior beam column joint subjected to cyclic loading. International Journal of engineering research and technology (IJERT) India, pp: 1409-1414.

- Li B, Xu L, Shi Y, Chi Y, Liu Q, et al. (2018) Effects of fiber type, volume fraction and aspect ratio on the flexural and acoustic emission behaviors of steel fiber reinforced concrete. Construction and Building Materials 181: 474-486.

- Fan M, Fu F Eds (2017) Advanced high strength natural fiber composites in construction. Woodhead Publishing, Ltd, Duxford, UK, p:74.

- Choo BS, Newman J (2003) Advanced Concrete Technology. (Four-Volume Set), MA: Elsevier, Burlington, USA, p: 1-4.

- Schabowicz K, Jóźwiak-Niedźwiedzka D, Ranachowski Z, Kudela S, Dvorak T (2018) Microstructural characterization of cellulose fibres in reinforced cement boards. Archives of Civil and Mechanical Engineering, 18(4): 1068-1078.

- Kustermann A, Keuser M (2004) High performance fiber reinforced concrete under high dynamic impact loading, in 6th RILEM Symposium on Fiber- Reinforced Concretes (FRC)-BEFIB, Varenna, Italy pp: 1217-1226.

- Rilem Technical Committee 49 TFR (1984) Testing methods for fibers reinforced cement-based composites 17(3): 239-254.

- ASTM (1992) Standard test method for flexural toughness and first crack strength of fiber reinforced concrete (using beam with third-point loading)-ASTM C 1018. ASTM Annual Book of Standards Philadelphia ASTM 04(02): 280-288.

- Johnston CD (1990) Methods of Evaluating the Performance of Fiber-Reinforced Concrete. In Materials Research Society Symposium Proceedings 21: 15-24.

- Van Gysel A, Taerwe L (1996) Analytical formulation of the complete stress-strain curve for high strength concrete. Materials and structures/Matériaux et constructions 29: 529-533.

- Parghi A, Modhera CK (2008) Mechanical Properties of Normal to High Strength Steel Fiber-Reinforced Concrete.

- Showmay Hsu L, Thomas Hsu CT (1994) Stress- strain behavior of steel-fiber high-strength concrete under compression. International Concrete Abstracts Portal, 91(4): 448-457.

- Foster SJ, Attard MM (2001) Strength and Ductility of Fiber-Reinforced High-Strength Concrete Columns. Journal of Structural Engineering 127(1): 28-34.

- Rols S (1996) Design of a ductile and durable cement-fiber composite of polypropylene. Thesis Doc. Ing, National Institute of Applied Sciences of Lyon.