The Role of the Pump in the Energy Certification of the Building

Maria Eördöghné Miklós*

Department of Mechanical Engineer, University of Pécs, Hungary

Submission: March 30,2021; Published: April 16, 2021

*Corresponding Author: Maria Eördöghné Miklós, Department of Mechanical Engineer, University of Pécs, 7624 Pécs, Boszorkány Str. 2, Hungary

How to cite this article: Maria Eördöghné M. The Role of the Pump in the Energy Certification of the Building. Civil Eng Res J. 2021; 11(4): 555817. DOI: 10.19080/CERJ.2021.11.555817

Abstract

Today, an important goal is to reduce the energy demand of buildings. To alleviate the use of primary energy there are a number of solutions. Background energy consumption, such as energy demand of pumping, can be affected by a number of methods. With the right choice of pump, the energy efficiency of pump systems is largely determined by the type of control and the adaptation to the operating modes, especially in the case of a variable load profile. The equivalent electrical energy consumption can be determined by a so-called energy parameter according to the characteristics of the given system parameter (water supply cubic meter, pressure level). This parameter is suitable for comparing the energy efficiency of different pump systems.

Keywords: Lifetime costs; Pumping work; Energy efficiency of pumps; Pump control modes; Pump operating parameters

Introduction

Any form of energy consumption involves losses. The elements of the network cause so-called direct losses, while the use of inappropriate equipment, oversizing etc. lead to indirect losses. Direct losses can be reduced by properly selecting the mode of operation, while indirect losses can be prevented or limited with the help of multidimensional calculations and considerations. These include the so-called: life cycle cost analysis. The energy costs representing the largest share of costs, which may reach 85%, can be reduced with the use of both planning and operating tools. The energy indicators of the new or upgraded systems can be optimized with planning tools. The energy efficiency of existing systems can be increased by the appropriate selection of the control mode, the operating parameters and the operation. This study aims to highlight the relationship of these latter ones based on actual measurements, and to allow a comparison, an assessment of the operating pumping stations by presenting the rating parameters defined for pumping systems [1].

Measurements

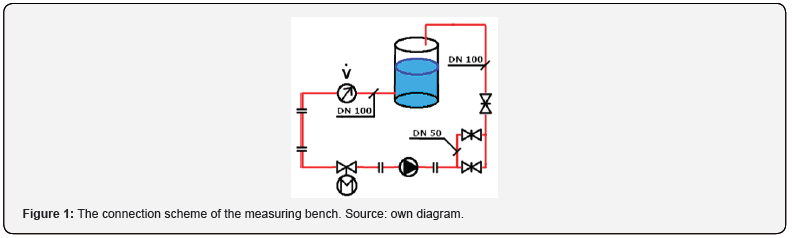

The analysis was performed based on the measurement/calculation of the operating parameters of the three pumps on a test cell arranged according to (Figure 1). The body of the pumps used for the measurements in all three cases was the same, only the motors mounted on them were different. The first pump had a traditional, constant-speed type (hereinafter CS) motor, the second one had the same type of motor with a frequency converter attached to it (hereinafter CFC), and the third one had a so-called “Saver1” motor [2].

Results

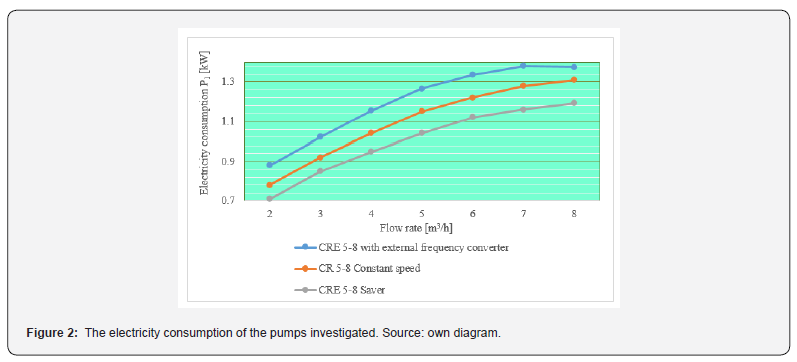

The power curve of the three pumps under investigation was drawn up at unregulated load (Figure 2). The diagram illustrates well that the electricity consumption of the pump unit with external frequency converter is higher at full load than that of the constant speed pump. This higher energy need occurs due to the losses arising from the “additional gear” of the external frequency converter. The energy-efficient nature of this pump design is most visible at partial load. The latest Saver drive had the lowest energy need, as expected [3].

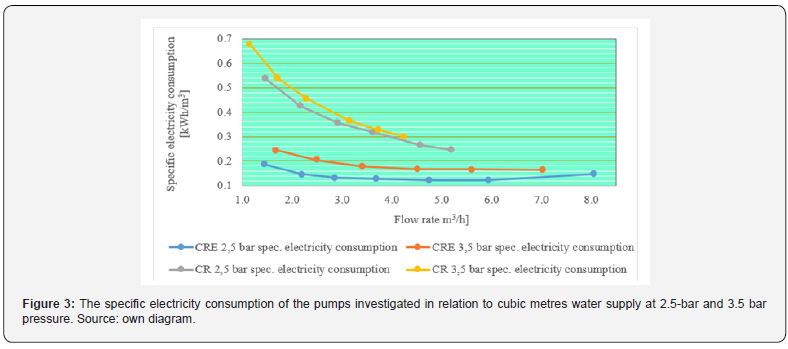

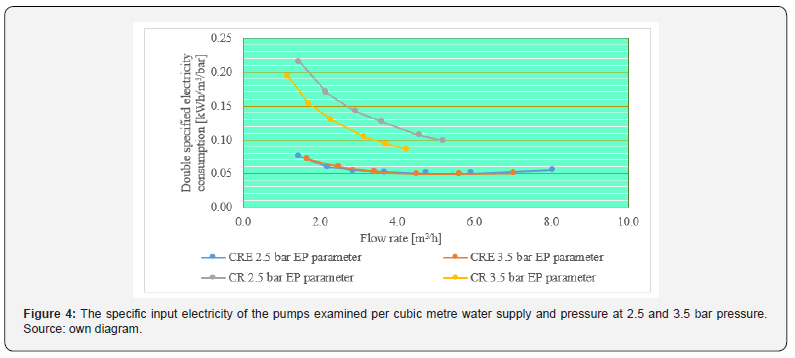

Water flow is also a principal parameter in the energetic review of pumping systems. The volume of electricity consumed per cubic meter water supply is analysed based on the measured data at 2.5 bar and 3.5 bar pressure levels (Figure 3). The comparison of the two diagrams shows that only the volume of specific electricity consumption changes, but the order of the pumps does not. The diagrams also indicate that while the change in specific electricity consumption is 50% in the full flow rate in Saver motors, the fluctuations between the minimum and the maximum values can be as much as 224% in the case of constant speed motor drives. When comparing the energy consumption of pumping stations, the pressure created is another parameter in addition to water supply that can influence energy consumption. The volume of electricity consumed was examined in relation to the cubic meter of water supplied at the same time and the pressure level, thus defining the energy parameter (EP). The results are shown in (Figure 4) [4].

The following conclusions can be drawn from Figure 4: a. constant speed drive shows lower water consumption, and partial load can be compensated by larger energy consumption;

b. the electrical consumption of pumping systems with variable speed drive is not affected by the flow rate or the pressure level, the electricity consumption of the engine adjusts to the variable load;

c. the energy parameters of the built-in variable speed and the permanent magnet synchronous motors (Saver motor) are the most favourable;

d. the EP values in Saver motors are almost the same over the full load range, including partial load compared to the other two types of regulation where lower flow rates are accompanied by higher electricity consumption.

EP could prove to be a particularly informative tool for the energy review or comparison of pumping stations, as well as for the decisions about the energy efficient upgrading of pumping systems. The specific values, kWh/m3, kWh/m3, bar can also provide information about the economy of operation and the financial savings, promoting refurbishments aimed at energy rationalization [5].

Conclusion

Translating the results of research and development into practice as soon as possible can contribute to the operational sustainability of production and infrastructure networks. It is, therefore, important to get to know the technical solutions and the possibilities of their adaption to the existing systems. This study draws attention to the energy savings opportunities offered by the regulation of pumping, particularly in the case of systems operating at partial load. The energy parameter (EP) can serve as a useful indicator when assessing the energy efficiency of a pumping system.

References

- Plath M, Wichmann K, Ludwig G (2010) Handbook Energy Efficiency / Energy Saving in Water Supply. Bonn: DVGW German Gas and Water Association e. v.

- Mária, Eördöghné Miklós (2011) Water Providers and Water Consumers for Sustainable Water Supply. (Water suppliers and consumers for a sustainable water supply.) Hungarian Building Engineering p. 8-11.

- Michael, Schulz (2003) System optimization by reducing the power consumption, IKZ-Haustechnik, 12. kött, old.

- http://www.braunschweig.ihk.de/

- http://www.braunschweig.ihk.de/fileadmin/v1/images/content/inhaltsbereich/02_artikelbilder/01_geschaeftsfelder/04_innovation_und_umwelt/02_umwelt/08_energieeffizienz_ig/00_downloads_artikel/5_Informationen_zu_Energieeinsparpotenzialen/Pumpensysteme_alle_F