- Review Article

- Abstract

- Introduction

- Presentation of the project

- Conception of the new pavement

- Design of the new pavement without geogrid

- Design of the New Pavement with Geogrid

- Comparative Cost Analysis Between the Structure without Geogrid and the Structure with Geogrid

- Recommendation of the use of Geogrids in Granular Pavement Layers

- Conclusion

- References

Reinforcement of Flexible Pavements by the Use of Geogrid: Case of the Road Mbalmayo - Ebolowa

Madjadoumbaye Jérémie* and Camela Woumbe Romario

Département de Génie Civil, Ecole Nationale Supérieure des Travaux Publics, France

Submission: July 01, 2019; Published: July 19, 2019

*Corresponding Author: Madjadoumbaye Jérémie, Département de Génie Civil, Ecole Nationale Supérieure des Travaux Publics, France

How to cite this article: Madjadoumbaye J, Camela W R. Reinforcement of Flexible Pavements by the Use of Geogrid: Case of the Road Mbalmayo - Ebolowa. Civil Eng Res J. 2019; 8(5): 555748. DOI: 10.19080/CERJ.2019.08.555748

- Review Article

- Abstract

- Introduction

- Presentation of the project

- Conception of the new pavement

- Design of the new pavement without geogrid

- Design of the New Pavement with Geogrid

- Comparative Cost Analysis Between the Structure without Geogrid and the Structure with Geogrid

- Recommendation of the use of Geogrids in Granular Pavement Layers

- Conclusion

- References

Abstract

The insufficiency of load-bearing capacity of a flexible pavement in service is generally caused by a significant increase in traffic. The consequence of this insufficiency is the appearance of severe damage to the surface layer. Therefore, this pavement must be reinforced with new layers. However, in view of the high costs of pavement materials, more economical reinforcement techniques must be developed. The purpose of this work is therefore to use geogrid to reinforce the new pavement of the approximately 104km long Mbalmayo-Ebolowa road section. The methodology used consisted in determining the layer thicknesses of the new pavement without geogrid, and then with geogrid. Then a comparative analysis of the costs of the two approaches was made. Using Alizé software, we therefore designed the new pavement structure for the sections to be rehabilitated, which have a total length of approximately 63.7km. Then, we determined the nature, characteristics and location of the geogrid to be used. MacREAD software allowed us to analyze the reinforced pavement and determine the final layer thicknesses. As a result, the MacGrid EG geogrid manufactured by MACCAFERRI was introduced into the base layer and reduced the required bituminous gravel thickness by 6cm. A comparative cost study showed us that the solution we proposed saved FCFA 2.3 billion, or about 36 million gains per kilometer..

Keywords: Pavement; Reinforcement; Geogrid

Abbrevations: AC: Asphalt Concrete; BTB: Bituminous Treated Base; SETRA: Service d’Etudes Techniques des Routes et Autoroutes

- Review Article

- Abstract

- Introduction

- Presentation of the project

- Conception of the new pavement

- Design of the new pavement without geogrid

- Design of the New Pavement with Geogrid

- Comparative Cost Analysis Between the Structure without Geogrid and the Structure with Geogrid

- Recommendation of the use of Geogrids in Granular Pavement Layers

- Conclusion

- References

Introduction

Road infrastructure plays a fundamental role in the development process of a country. More precisely, they are one of the pivots of economic activity, strategic operations and accessibility to public services. Cameroon, in search of emergence, must nowadays face the multiple problems that its road heritage faces. On the one hand, new roads must be built that will not only be suitable for the ever-increasing volume of traffic on most of the country’s major roads, but also ensure the excellent mobility desired by users and essential for the economy’s development. On the other hand, it is necessary to look at existing roads, whose deplorable condition is an obstacle to development.

Indeed, several road infrastructures in Cameroon are degraded, both in urban and rural areas. This poor road condition not only puts users at risk, but also disrupts traffic, thereby hindering the development of economic activity. Faced with this problem, Cameroon’s road network managers are undertaking maintenance work, or even pavement reinforcement work, in order to eliminate pathologies and restore the pavement to the desired level of service. For example, the heavy maintenance project for the road section between Mbalmayo and Ebolowa has been undertaken. This 104km long section has become almost impassable because of the degradations it has suffered. These degradations are the result of a lack of load-bearing capacity of the structure due to an explosion in the volume of traffic on the road. But faced with the exorbitant cost of road materials, we are now forced to look for more economical construction techniques. The general objective of this article is to provide a less expensive method of flexible pavement reinforcement using a geogrid. This work begins with the presentation of the characteristics of the initial pavement and the available materials. Then, we will design the new pavement in a first one without geogrid, and then with geogrid. A comparative cost analysis between the two approaches will be done at the end./p>

- Review Article

- Abstract

- Introduction

- Presentation of the project

- Conception of the new pavement

- Design of the new pavement without geogrid

- Design of the New Pavement with Geogrid

- Comparative Cost Analysis Between the Structure without Geogrid and the Structure with Geogrid

- Recommendation of the use of Geogrids in Granular Pavement Layers

- Conclusion

- References

Presentation of the project

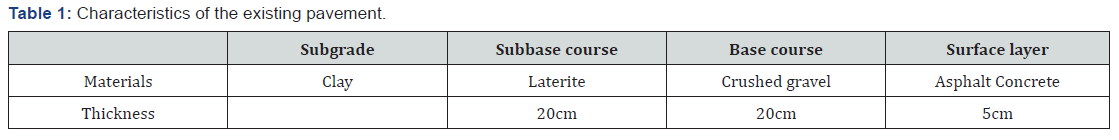

The Mbalmayo-Ebolowa section is approximately 104km long with a 7m wide pavement (but the sections to be rehabilitated are 63.7km long). This pavement is now subject to very heavy traffic, class To according to the classification of the Service d’Etudes Techniques des Routes et Autoroutes [1].The pavement is degraded throughout and along its entire route, with the exception of recently rehabilitated sections. The project therefore consists in making a new pavement that will be able to withstand current and future traffic. Table 1 presents the characteristics of the pavement materials in place.

- Review Article

- Abstract

- Introduction

- Presentation of the project

- Conception of the new pavement

- Design of the new pavement without geogrid

- Design of the New Pavement with Geogrid

- Comparative Cost Analysis Between the Structure without Geogrid and the Structure with Geogrid

- Recommendation of the use of Geogrids in Granular Pavement Layers

- Conclusion

- References i>

Conception of the new pavement

The materials of the existing pavement and base layer will be recycled to form the base layer of the new pavement. The old sub-base (lateritic gravel) will be considered as the new support platform. The new base layer will be made of Bituminous Treated Base (BTB) and the new wearing course will be made of Asphalt Concrete (AC). Table 2 presents the characteristics of the materials to be used for the new pavement.

- Review Article

- Abstract

- Introduction

- Presentation of the project

- Conception of the new pavement

- Design of the new pavement without geogrid

- Design of the New Pavement with Geogrid

- Comparative Cost Analysis Between the Structure without Geogrid and the Structure with Geogrid

- Recommendation of the use of Geogrids in Granular Pavement Layers

- Conclusion

- References

Design of the new pavement without geogrid

The French method of pavement design is the one used in Cameroon. This is the method that will be used here via its Alizé- LCPC Routes software.

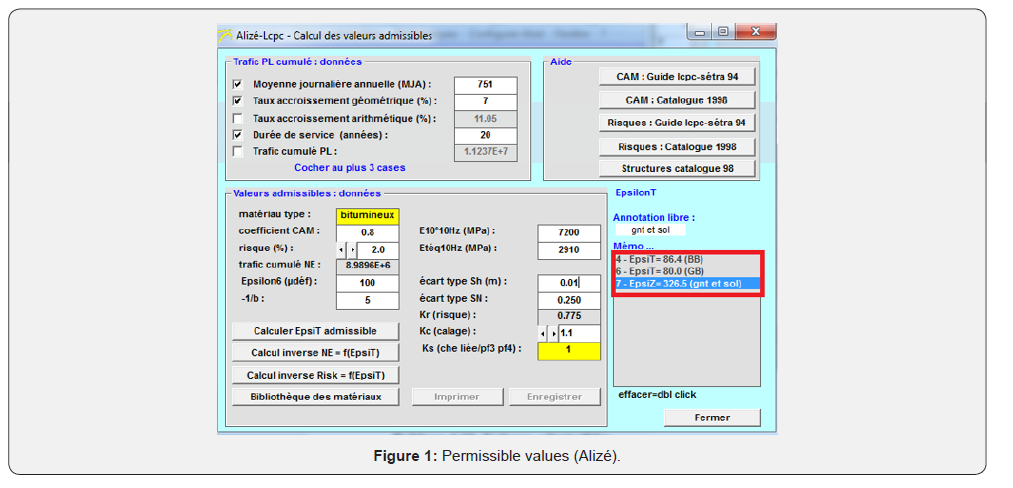

Calculation of permissible values

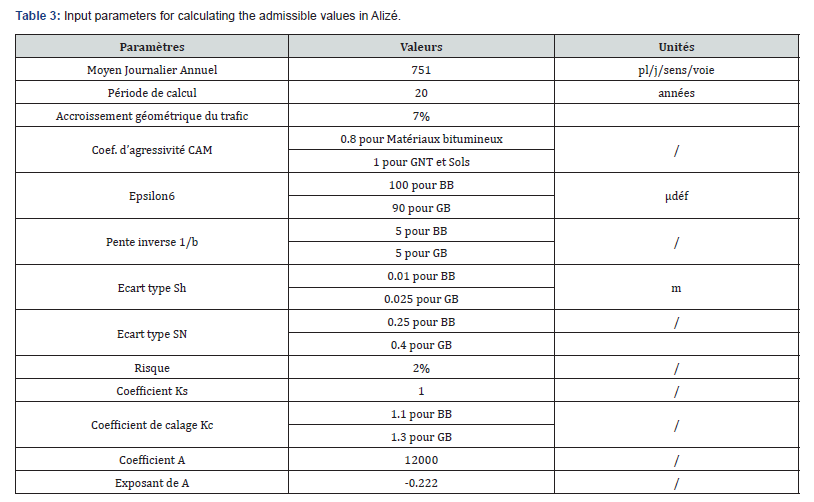

The input parameters for calculating the permissible values are presented in Table 3. These parameters were determined using the project data and the guide Conception De Dimensionnement Des Structures De Chaussée [2].

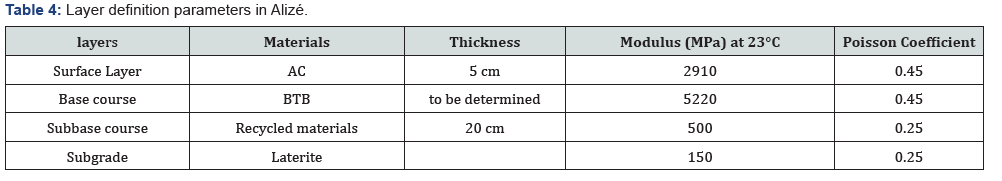

Calculation of layers thicknesses

The thicknesses of the wearing course and sub-base are fixed. The only thickness to be calculated is that of the base layer. The calculation will be done by incrementing the thickness of the base layer (BTB) from 10cm which is its minimum implementation value according to SETRA. The incrementation is completed when the deformations obtained are lower than the permissible values. Table 4 presents the parameters for defining the layers in Alizé.

Results

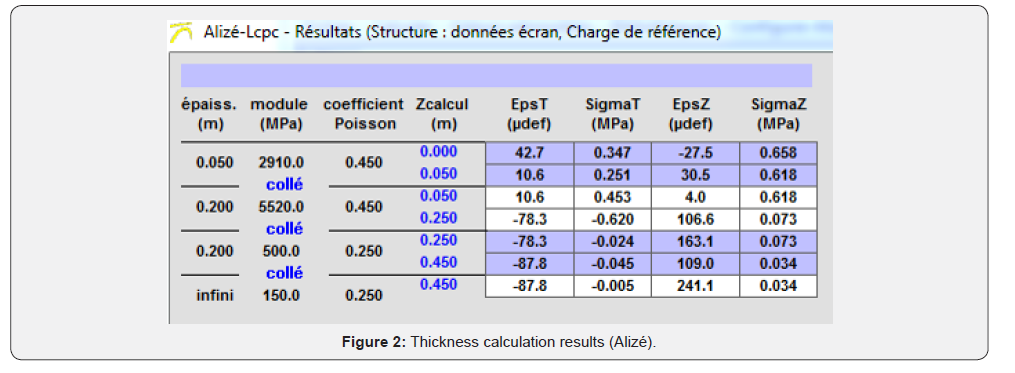

Figure 1, Figure 2 show the results of the calculation of the permissible values and thicknesses of the pavement layers respectively. According to these results, the admissible values obtained are 86.4μ (at the base of the asphalt concrete layer), 80μ (at the base of the BTB layer) and 326.5μ (at the surface of the subgrade soil and untreated layers).According to these results,the horizontal deformation at the base of the wearing course, the horizontal deformation at the base of the base course and the vertical deformation at the surface of the untreated layers and the subgrade are 10.6μ, 78.3μ and 241.1μ respectively. These values are then lower than the corresponding admissible values. The structure is therefore checked. The thickness of the base layer then required is 20cm.

- Review Article

- Abstract

- Introduction

- Presentation of the project

- Conception of the new pavement

- Design of the new pavement without geogrid

- Design of the New Pavement with Geogrid

- Comparative Cost Analysis Between the Structure without Geogrid and the Structure with Geogrid

- Recommendation of the use of Geogrids in Granular Pavement Layers

- Conclusion

- References

Design of the New Pavement with Geogrid

The MacGrid EG 30S geogrid manufactured by MACCAFERRI will be used to reinforce the base layer, which is made of bituminous gravel. The numerical simulation will be carried out by the MacREAD software designed by the same company for the design of pavements with geogrid reinforcement. The sizing method used by MacREAD is the American AASHTO method. Since the results given by MacREAD also include the results of calculations of the structure without geogrid, we will just make sure that these results are the same as those obtained by Alizé.

Input parameters

The input parameters for the calculation are given in Table 4. These parameters were determined using project data and the Guide for design of pavement structures [3]. It should be noted that the characteristics of the MacGrid EG 30S geogrid are already defined in the MacREAD software.

Calculation result

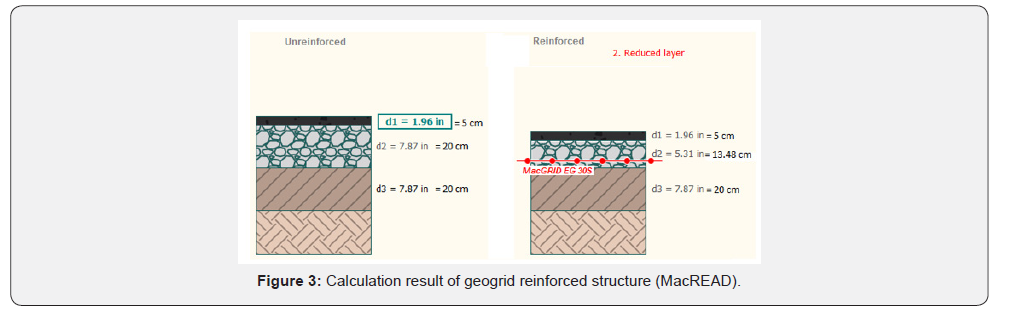

Figure 3 shows the results of the calculation of the geogrid reinforced structure. These results show that the geogrid has reduced the required thickness of the base layer from 20cm to 13.48cm, which will be rounded to 15cm to facilitate implementation. That is a reduction of 5cm.

- Review Article

- Abstract

- Introduction

- Presentation of the project

- Conception of the new pavement

- Design of the new pavement without geogrid

- Design of the New Pavement with Geogrid

- Comparative Cost Analysis Between the Structure without Geogrid and the Structure with Geogrid

- Recommendation of the use of Geogrids in Granular Pavement Layers

- Conclusion

- References

Comparative Cost Analysis Between the Structure without Geogrid and the Structure with Geogrid

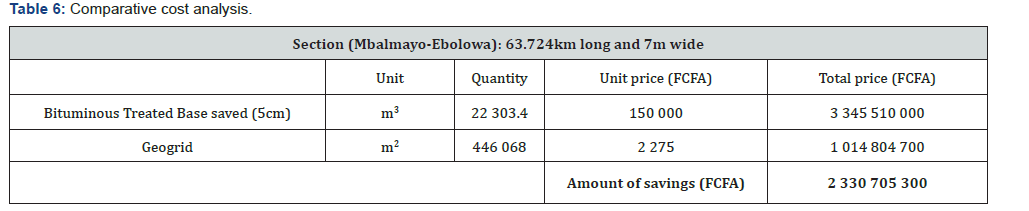

The comparative cost analysis is summarized by comparing the cost of the geogrid required with the cost of the quantity of BTB saved. The calculation of costs is presented in (Table 5 & Table 6).

- Review Article

- Abstract

- Introduction

- Presentation of the project

- Conception of the new pavement

- Design of the new pavement without geogrid

- Design of the New Pavement with Geogrid

- Comparative Cost Analysis Between the Structure without Geogrid and the Structure with Geogrid

- Recommendation of the use of Geogrids in Granular Pavement Layers

- Conclusion

- References

Recommendation of the use of Geogrids in Granular Pavement Layers

Based on the results of the cost analysis, we see that using geogrid in the base layer is a great economical technique. We therefore recommend the use of this product in future projects. Note that the manufacturer of the geogrid used recommends that it be used only in granular layers [4-5].

- Review Article

- Abstract

- Introduction

- Presentation of the project

- Conception of the new pavement

- Design of the new pavement without geogrid

- Design of the New Pavement with Geogrid

- Comparative Cost Analysis Between the Structure without Geogrid and the Structure with Geogrid

- Recommendation of the use of Geogrids in Granular Pavement Layers

- Conclusion

- References

Conclusion

During this work we clearly demonstrated by numerical modelling that the problem of high cost of pavement materials can be alleviated by the use of geogrids to reinforce granular layers. The project that we used as a case study is the reinforcement of the Mbalmayo - Ebolowa road section, whose total length of the sections to be reinforced was 63km. We have shown that the use of the MacGrid EG 30S geogrid in the base layer reduces the required bituminous gravel thickness by 6cm. This corresponds to savings of more than FCFA 2.3 billion, or about FCFA 36 million in gains per kilometer.

- Review Article

- Abstract

- Introduction

- Presentation of the project

- Conception of the new pavement

- Design of the new pavement without geogrid

- Design of the New Pavement with Geogrid

- Comparative Cost Analysis Between the Structure without Geogrid and the Structure with Geogrid

- Recommendation of the use of Geogrids in Granular Pavement Layers

- Conclusion

- References

References

- SETRA (1998) Catalogue des structures types de chaussées neuves, SETRA/LCPC. Pp. 1-321.

- SETRA (1994) Conception et dimensionnement des structures de chaussée, LCPC/SETRA. Pp. 1-260.

- AASHTO (1993) Guide for design of pavement structures, USA. Pp. 1-624.

- SETRA (1978) Dimensionnement des renforcements de chaussées souples, SETRA/LCPC. Pp 1-52.

- CFG (2015) Définition mise en œuvre et dimensionnement des géosynthétiques, Groupe Moniteur SAS. Pp 1-40.