Evaluation of the Healing Conditions in Strength Recovery in Concretes Early Loaded (Self-Healing)

Pietra Moraes Borges1, Matheus Chiaradia Wenzel1, Jéssica Zamboni2, Sérgio Roberto da Silva2 and Jairo José de Oliveira Andrade2

1Pontifical Catholic University of Rio Grande do Sul (PUCRS), Brazil

2Graduation Program in Materials Engineering and Technology, Pontifical Catholic University of Rio Grande do Sul (PGETEMA/PUCRS), Brazil

Submission: April 01, 2019; Published: April 15, 2019

*Corresponding Author: Jairo José de Oliveira Andrade, Graduation Program in Materials Engineering and Technology, Pontifical Catholic University of Rio Grande do Sul (PGETEMA/PUCRS), Brazil

How to cite this article: Pietra M B, Matheus C W, Jéssica Z, Sérgio R d S, Jairo J d O A. Evaluation of the Healing Conditions in Strength Recovery in Concretes Early Loaded (Self-Healing). Civil Eng Res J. 2019; 8(1): 555728. DOI: 10.19080/CERJ.2019.08.555728

Abstract

This article focuses in self-healing effect in compressive strength recovery of concretes early load submitted at two different cure procedures: immersion on water and accelerated carbonation. This way was applied loads in concrete test specimens after 3 and 7 days of cure with a load equivalent to 25%, 50% and 75% of the ultimate load. The specimens were broken at ages of 28 and 91 days and the main mechanical properties of concretes were investigated (compressive, tensile strength and modulus of elasticity) after 28 and 91 days in cure methods presented. The results showed that cure procedures have a significant influence in all properties investigated

Keywords: Concrete; Preload; Self-Healing; Mechanical Properties; Maintenance; Materials

Introduction

The properties of concrete such as the ability to work with different resistance levels and the facility of molding in many forms makes concrete one of the most used materials in the world since little construction until big bridges [1]. The progress in materials engineering and in the scaling, software leads to slender structures and this characteristic promotes de appearance of cracks in concrete as commented by Ter Heide [2]. Inside of these new construction methods is the early withdrawal of forms, such a habit leads to a pre-load in structures not allowed to receive such load at ages of 3 to 7 days. The onset of microcracks harms concrete durability and compressive strength as demonstrated by Silva et al. [3]. The loss of durability leads to economical damage caused by the costs of maintenance and excessive use of materials. From the problem of cracks and loss of durability was studied by Wu, et al [4] a process named self-healing. The procedure consists of several possible solutions for concrete to regain it’s durability and resistance from an autogenous microcrack closure system.

Chemically speaking the process is based by the deposition of calcium carbonate in the open cracks. In the case by curing on immersion in water the deposition occurs from the late hydration on cementitious compounds (significantly large in concretes with pozzolanic cement such as CPIV that acquire more resistance in long ages)and in the accelerated carbonation chamber, the process occurs due to the carbonation phenomenon itself where the CO2 of the chamber reacts with the humidity and, from the reaction between the carbonic acid and the Ca(OH)2 of the concrete, generates a compound called CaCO3 or calcium carbonate. Li & Yang, et al. [5] reinforce the importance of the self-healing process for the recovery of concretes that, without this phenomenon, would have their durability impaired.

Materials and methods

The sand originated from Jacuí River, a large aggregate with basaltic origin and Portland cement CPIV were used due to availability in Porto Alegre region. The fine aggregate was specific and unitary mass of 2,60 and 1,53kg/dm³ respectively and fineness module of 1.31, already the large aggregate was values of 2,75 and 1,50kg/dm³. All the characterization tests were made as said in the Brazilians standards. The unit mass trait of 1:2,18:2,82 (cement: sand: gravel) with water-cement radio w/c=0,56 was used. The molded concrete with such characteristics had a slump of 70±10mm. With consumption of materials as shown in Table 1.

The ages of 3 and 7 days after molding were applied for preload application. Besides that, were chosen different load percentages in the concrete, corresponding to 25, 50 and 75% of the breaking load of material. After the application of the pre-loading the specimens were left in water immersion cure and carbonation chamber for 28 and 91 days in the same way as done by Silva [3] and Venquiaruto. For the immersion in water method was used prismatic specimens with 15x15x50cm and for the carbonation chamber was used prismatic specimens with 10x10x30cm to the detriment of the chamber’s carrying capacity. For the curing environment in the accelerated carbonation chamber a CO2 concentration of 3% was used, with internal pressure equivalent to atmospheric pressure plus 0.5 bar and relative humidity between 60% -70% and 5%. Were molded, in total, 83 specimens between prismatic and cylindrical used for tests of compressive strength, modulus of elasticity and tensile in flexion.

Results

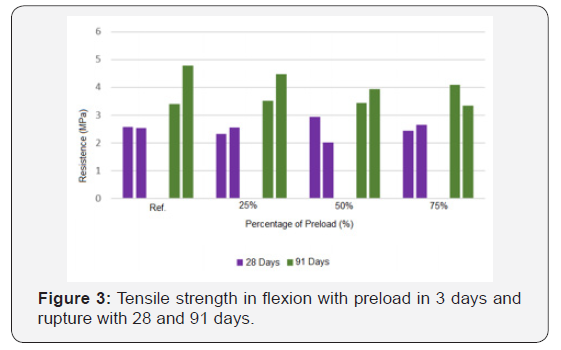

Initially it was necessary to determine the appropriate parameter aiming to compare the strengths of prismatic specimens with different dimensions. For this, the theory of materials’ resistance was used as presented by Hibbeler [6], obtaining equations 1 and 2, which take into account the moment of inertia of the cross section of the specimen and the bending moment applied.

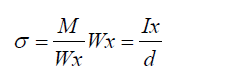

To the cure by immersion on water with preload in 3 days the behavior was the presented in Figure 1. It is possible to observe a tendency of increase of resistance the greater the curing time due to the better hydration of the cementitious matrix, as well as the tendency of reference specimens to have a greater resistance, since they were not subjected to any type of pre-load. It can also be observed that, on average, all specimens with preload of 25 or 50% had a similar behavior, regardless of the percentage of the burst load applied to them. However, they presented a resistance minimization in comparison to the reference, which can be attributed to the induced microcracks. Already the specimens loaded with 75% of the bursting charge had a higher self-healing process. This is due to the fact that the larger the force applied the larger the microcracks, allowing a greater penetration of water in the matrix, having a greater contact area of the water with the grains not yet hydrated, potentializing the process of autogenous closure of these cracks. These results were similar to those found by Silva [4], whose author investigating the influence of preloading found a similar trend.

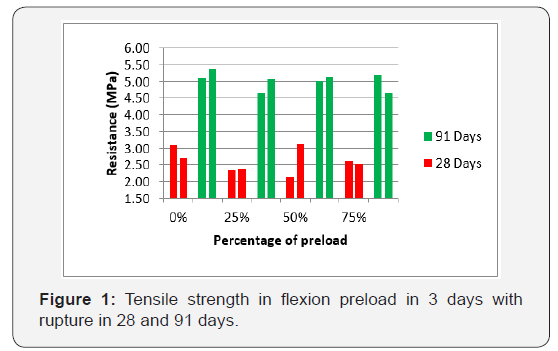

The specimens preloaded with 7 days of cure are present in Figure 2 which showed less loss of resistance compared with the behavior of concretes loaded with 3 days. This result it is related with the resistance already acquired with 7 days in immersion highlighting the importance of the correct cure of the elements in first ages. However, a tendency is observed for the decrease in the recovery of the resistance with tension equal to 75% of the rupture load, because this behavior possibly occurs due to the direct relation between the preload load and the lost resistance of the material, considering that at 7 days the hydration process was already more advanced.

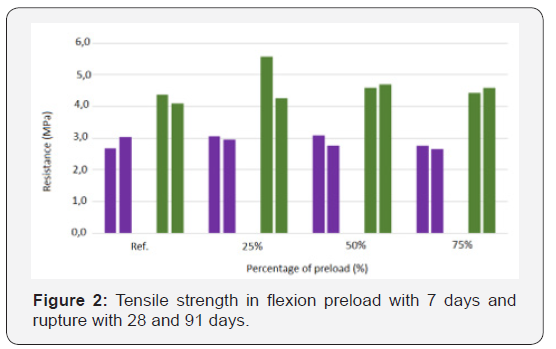

Weren’t found any papers who evaluate the influence of accelerated carbonation in the process of self-healing. Carbonation, always associated with loss of durability, can be used as an alternative for the self-healing process in no armed concrete due to the closing of microcracks based in the deposition of CaCO3 inside de crack. The results of the tensile strength in flexion test are presented in Figure 3.

It’s possible to see that, independent of the preload percentage, the resistance of the specimens is almost the same showing that accelerated carbonation is an option to the self-healing process. The carbonation was a slower reaction due to the velocity of the chemistry in each process (immersion in water and accelerated carbonation).

Conclusion

It was verified that the greater the healing time, the greater the effect of the self-healing process, evidencing that the magnitude of this process is directly related to the time the material remains exposed to the curing method. However, a significant tendency of the preloaded specimens to be observed within 3 days of a larger recovery was observed when the preloading percentage was higher, whose specimens loaded with 75% of the bursting load had a behavior slightly higher than those were preloaded with less load, with results similar to those obtained by Silva [4]. In addition the following considerations can be made:

i. All the results of the tensile strength test in flexion had a relatively large variability, however, when compared with the results obtained with similar researches such as Silva [4].

ii. As for the healing environment, it is possible to emphasize the importance of humid cure in the continuity of the resistance and the durability of the materials. However, the curing process in the carbonation chamber, despite being an accelerated process, showed potential in the closing of the microcracks, having an amplitude of results tending to be smaller than the immersion curing method due to the speed of the carbonation process in comparison with the speed of the hydration process of the material.

iii. Considering the influence of the pre-loading time, it was verified that at 3 days the process of self-healing has a tendency to be favored, since the cure is still in its initial stage, having a greater quantity of non-hydrated grains with possibility of hydration , helping to close the microcracks. As for the pre-loading process at 7 days, where part of the hydrated grains is already present, the magnitude of the delayed hydration would become smaller than at 3 days.

References

- Mehta PK, Monteiro PJM (2008) Concrete: Microstructure, properties and materials. (4th edn), McGraw-Hill Education: New York, Chicago, USA, p. 674.

- Ter Heide N (2005) Crack healing in hydrating concrete. Faculty of Civil Engineering and Geosciences, Delft University of Technology, Netherlands, p.118.

- Silva LB (2016) Evaluation of preload in the draying retraction in concrete. Programa de Pós-Graduação em Engenharia Civil, UFRGS, Porto Alegre, Brazil, p. 392.

- Wu M, Johannesson B, Geiker M (2012) A review: Self-healing in cementitious materials and engineered cementitious composite as a self-healing material. Construction and Building Materials 28(1): 571-583.

- Li CV, Yang EH (2007) Self-Healing in Concrete Materials. In: Zwaag SVD (Ed.), Self-Healing Materials: An Alternative Approach to 20 Centuries of Materials Science. The Netherlands: Springer, p.161-194.

- Hibbeler RC (2000) Resistence of materials. Terceira Edição, Livros Técnicos e Científicos Editora, Rio de Janeiro.