Influence of Fibres on the Rebar - Concrete Bond: Further Evidence of Toughness Enhancement

Brigitte Goffin* and Nemkumar Banthia

Department of Civil Engineering, University of British Columbia, Canada

Submission: November 11, 2017; Published: February 21, 2018

*Corresponding author: Brigitte Goffin, Department of Civil Engineering, University of British Columbia, 1012J-6250 Applied Science Lane, V6T 1Z4, Vancouver, BC, Canada, Tel: +1-604-822-6039; Email: goffin@civil.ubc.ca

How to cite this article: Brigitte Goffin, Nemkumar Banthia. Brigitte Goffin* and Nemkumar Banthia. Civil Eng Res J. 2018; 3(3): 555615. DOI: 10.19080/CERJ.2018.03.555615

Abstract

The bond between the rebar and the surrounding concrete plays a substantial role in the mechanical performance of a reinforced concrete member due to the stress transfer that occurs at the aforementioned interface. In this study direct rebar pull out tests were performed at different concrete maturities, fibre contents and fibre materials. PET fibres that have a lower energy requirement during production and improved properties in comparison to polypropylene were used and their performance compared to steel fibres. The addition of fibres leads to a more ductile failure during pull-out. The improved energy absorption capacity is particularly important under seismic loading. Interestingly, a small amount of fibres is enough to notably improve the post-failure behaviour by reducing the softening slope of the stress-slip curve. An increase in fibre content beyond 0.1% for PET fibres does not improve the post-failure behaviour any further. However, steel fibres continue to improve the post-peak behaviour. Thus, the effect of steel fibres is more significant compared to PET fibres and the most pronounced at a high concrete maturity. An analytical model describing the bond stress slip response is proposed and matches the experimental observations well.

Keywords: Fibre reinforced concrete; Bond; Rebar pull-out; Modelling

Introduction

The bond between the rebar and the surrounding concrete plays a substantial role in the mechanical performance of a reinforced concrete member due to the stress transfer that occurs at the concrete-rebar interface. The quality of the bond, and thus the extent of the force transfer, depends greatly on the composition of the concrete and any inclusions such as fibre reinforcement. Researchers worldwide have varied and at times contradicting opinions on the effects of fibres on the rebar- concrete bond strength.

The majority of scientists use the pull-out test to determine the bond characteristics of the rebar-matrix composite [1,2]. Other researchers [3,4] have used beam specimens subjected to a flexural load to analyse the bond-slip response of the rebar embedded in FRC. Unlike the flexural specimen, the pull-out specimen underestimates the bond strength of reinforcing bars in tension [3,4]. In other words, the bond strength obtained from flexural tests is larger than the equivalent value from direct pull- out tests [3]. However, reported qualitative improvements due to the addition of fibres, if any, are comparable for the two test set-ups.

Flexural tests performed by Harajli et al. [4] and direct pull-out tests done by Hota & Naaman [1] led to the conclusion that steel fibres improve the bond between the rebar and the surrounding matrix. The higher the fibre contents the higher was the obtained bond strength. Rostasy & Hartwich [2] as well as Osifala et al. [5] performed direct pull-out tests and Dancygier et al. [3] undertook flexural and direct pull-out tests that showed that fibres do not influence the rebar-matrix bond strength in a positive manner. Osifala et al. [5] and Dancygier et al. [3] even show a negative impact of the micro-reinforcement on the bond strength [3].

Even though fibres seem to be increasing the post-peak ductility [1,2] of pull-out specimens, the stiffness of the bond does not appear to be improved by the addition of the fibre- reinforcement [2]. Nonetheless, the improved softening slope indicates increased energy absorption, which is particularly beneficial under seismic loading. Improved seismic performance can result in the ability to repair after an earthquake has occurred rather than having to destruct and rebuild.

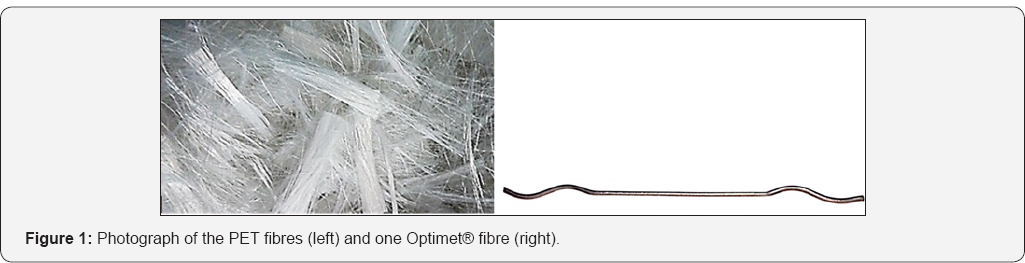

However, most experimental studies only included steel fibres and were performed during the 1990s and early 2000s [1,2,4,6]. During the last decade many improvements have been made in the field of fibre characteristics and consequently their structural performance. The sustainability movement has gained significant momentum globally. Since the early 2000s and led to the use of polyethylene terephthalate- PET - fibres as micro-reinforcement for concrete [7]. PET fibres are made of a synthetic material belonging to the polyester group [8]. The renewed interest in PET fibre as concrete reinforcement is due to its improved hydrophilic nature over polypropylene, lower energy requirement in production and higher elastic modulus. While the performance of structural members with both steel bar and PET fibre reinforcement has been studied by various researchers [9,10] no further studies have considered rebar- concrete bond with PET fibre (Figure 1).

A variety of analytical models, that attempt to describe the interfacial bond behaviour of rebar in concrete, can be found in the literature. However, while some models are limited to one failure mode [2,6] others could not be verified by experimental data [1]. Furthermore, many models do not account for the effect of fibres on the rebar concrete bond [6,11] or the concrete maturity [2-4,11,12]. The most comprehensive model describing the bond slip behaviour of rebars in fibre reinforced concrete under monotonic loading appears to be the one proposed by Harajli et al. [4] in 2002. The experimental data verifying the analytical model was obtained by flexural pull out tests [4]. The aforementioned model has become the basis of the effect of fibres in the more recent model by Huang et al. [12].

Nonetheless, the authors were unable to find an analytical model, predicting the failure behaviour for direct pull-out tests that include the influence of the fibre type, concrete maturity and compressive strength, in the literature.

Within the scope of the experimental investigation direct rebar pull out tests were performed at different concrete maturities, fibre contents and fibre materials - steel and PET An analytical model describing the bond stress-slip response is proposed and the model predictions are compared to the experimental observations.

Materials and Methods

Materials

A concrete with a maximum aggregate size of 19mm and a specified strength of 42MPa after 28 days was utilized for the specimens. The water to cement ratio was 0.55. Standard weld able 10M rebars were used as bar reinforcement for the specimens. This type of rebar has a nominal diameter of 11.3mm and a cross sectional area of 100mm2.

The micro steel reinforcement consisted of Optimet® fibres, which are made of high tensile cold drawn wire (Optimet Concrete Products, n.d.). The latter material has a minimum ultimate tensile strength ranging from 1 GPA to 2 GPA.Undulated deformations at the ends of the fibre increase its pull-out resistance (Optimet Concrete Products, n.d.). This fibre type shows excellent flexural toughness performance with no finishing constraints. The minimum available length was used in this study equalling 30mm (Optimet Concrete Products, n.d.). RECRON fibres from Reliance Industries Ltd. were chosen as synthetic micro-reinforcement.

The PET fibres were 18mm long to allow for comparison with the 30mm steel fibres. The specific gravity of the PET fibres ranges from 1.34 to 1.39.

Specimens

Within the scope of this study cylindrical specimens were cast, each reinforced with a 10M reinforcing bar located in the centre of the specimen, parallel to the cylinder's axis. The concrete specimens had diameters of 100mm and heights of 200mm. The embedment length of the rebar was 100mm.

The rebar pull-out tests were performed for five different kinds of specimens. The fibre volume fraction as well as fibre type of each kind of specimen is shown in Table 1.

Testing

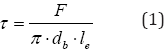

The pull-out test was displacement controlled. During the test the position of the top of the rebar was fixed and the concrete cylinder was pulled down at a constant speed of 1.6mm/min.

The displacement of the cylinder was measured with a LVDT and a strain gauge was used to record the rebar strain. Furthermore, the applied load was recorded. The concrete maturities at the time of testing were chosen to be 1 day, 7 days and 28 days.

Data analysis

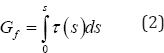

Bond stress and fracture energy analysis: The data acquisition system recorded the tensile force F applied to the specimen. In order to evaluate the shear stress at the rebar- concrete interface, the shape of the rebar was assumed to be a cylinder with constant diameter db of 11.3mm. Consequently, the bond stress xwas determined by Eq (1), where le denotes the embedment length. Please note a uniform stress transfer was assumed along the interface.

Once the interfacial stress was determined, the unit fracture energy Gf could be approximated by its integral over the slip s as shown in Eq (2).

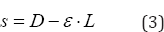

Slip analysis: The LVDT measured the displacement of the concrete cylinder. Consequently, the LVDT measurement consisted of both the rebar slip and the rebar strain. It was assumed that the recorded rebar strain was uniform along the entire free length of the rebar. Consequently, the slip s was determined with Eq. (3), where D is the displacement recorded by the LVDT, s is the recorded rebar strain and L is the free length of the rebar (Figure 2).

The largest strain was recorded for a steel fibre content of 0.5% at a concrete maturity of 28 days. The bond stress slip curve and the unit fracture energy of the aforementioned specimen are shown in Figure 3 & 4 respectively. The slip was determined with Eq.(3) for the dashed graphs labelled "Exact Slip". The slip of the grey graphs labelled 'Approximated Slip" is equal to the LVDT recording. Thus, the approximated slip is based on the assumption that the second term of Eq.(3), consisting of the product of the strain s and the free length L, is negligible.

The slight horizontal shift between the two graphs in Figure 3 is caused by the rebar strain and is equal to the second term of Eq.(3) (i.e. the product of the strain s and the free length L). The maximum shift is 0.387mm and corresponds to a bond stress of 12.8MPa and a LVDT recording of 5.466mm. Consequently, 7% of the recorded displacement was due to rebar strain. The strain term of Eq. (3) never exceeded 8% of the recorded displacement D.

The unit fracture energy was determined by the integral of the bond stress slip curve. Consequently, the unit fracture energy is affected by a horizontal shift of the bond stress slip curve. The resulting curve of the unit fracture energy over the slip is shown in Figure 4. The two curves are almost identical until unit fracture energy of 52N/mm corresponding to a slip of 7mm is reached. Larger slips result in higher unit fracture energy with the slip approximation in comparison to the exact slip of Eq. (3). At a slip of 20mm, the difference in unit fracture energy determined with the approximated and exact slip is 1.99N/mm, which equals 2% of the exact unit fracture energy.

Within the scope of this study, a maximum error of the approximated slip of 8% and the unit fracture energy of 2% at a given slip was deemed acceptable. Thus, within this study, the rebar slip was approximated by the LVDT recordings and the unit fracture energy was determined accordingly.

Analytical model

An analytical model describing the bond stress-slip response of indirect flexural pull-out tests [4] was modified to fit the response of the series of direct pull-out tests of the discussed study.

The focus of the modifications laid on the post-peak behaviour and took the sample age as well as the fibre type into account in addition to the parameters and variables used in the original model. A substantial number of formulas had to be modified and new parameters were introduced to determine the bond stress of the direct pull-out tests. However, the evaluation of the slip could not be achieved with a simple alteration of the original model. New formulas were introduced to evaluate the slip at four different points of the bond stress-slip curve.

Results and Discussion

Influence of age

Peak bond stress: The age and thus the maturity of the concrete play an important role when discussing the concrete strength and the rebar-matrix bond. With increasing age the bond strength of a specimen increased as is shown in all 3 diagrams (Figure 5-7). The bond strength increased by 125% within the first week and by 20% within the following 3 weeks. The compressive strength of the concrete increased by 200% within the first week and by 40% within the following 3 weeks. Hence, the bond strength greatly depends on the concrete maturity and consequently the concrete compressive strength.

Nonetheless, the bond strength only increased at approximately half the rate of the compressive strength.

The most significant increase in bond strength was observed between a maturity of one and seven days for all specimen types. The bond strength of the reference specimens showed an increase of approximately 1MPa in the following 21 days, whereas the peak bond stress of the fibre reinforced specimens increased by at least 2MPa.

Slope and failure mode: The initial slope was similar for all the curves with a tendency to be steeper for higher concrete ages. In other words, the diagrams indicate similar stiffness for all concrete ages with a tendency to be larger for higher concrete maturities.

Once the ultimate stress had been reached the slope varies greatly between the different concrete maturities. The failure appeared to be of a more brittle nature the more mature the concrete was. This resulted in a more sudden drop in load carrying capacity once the peak stress had been reached.

In the case of plain concrete, pull out failure occurred at a maturity of 1 day and splitting failure occurred at concrete ages of 7 and 28 days. The addition of fibres improved the failure mode at 7 days from splitting to pull out. However, only the steel fibres affected the failure mode at 28 days and led to pull out failure. [Figure 8-10]

Fracture energy: The unit fracture energy increased with increasing concrete maturity. The transition of the unit fracture energy as a function of the slip from the pre-fracture to the postfracture zone was very smooth for early ages due to the more ductile behaviour. The more brittle behaviour with increasing maturity resulted in an abrupt change of slope of the unit fracture energy curve at the instant of concrete fracture.

The unit fracture energy of the Reference and the PET fibre reinforced specimens increased significantly between the ages of 1 day and 7 days and only marginally between the ages of 7 days and 28 days as shown in Figure 8 & 9. The steel fibre reinforced specimens however showed a substantial increase between 7 days and 28 days of 25N/mm at a slip of 15mm.

This is explained by the improvement of failure mode from splitting to pull out. Even though the peak stress increased between 7 and 28 days for the plain and PET fibre reinforced specimens, the unit fracture energy did not increase because the 28 day failure mode was splitting. Once splitting had occurred, the confinement and thus friction at the rebar-concrete interface was greatly reduced. As a result, the increase in unit fracture energy post splitting was minimal.

Influence of Fibre Content

Peak Bond Stress: The magnitude of the maximum applied load - and thus the maximum interfacial stress - was not influenced by the synthetic fibre content. Steel fibres led to a small increase of the peak bond stress of 8%. This rise in peak stress is achieved by 0.2% fibre content and did not increase further with the addition of more fibres. Furthermore, it was observed that the coefficient of variation of the peak stress at a maturity of 28 days, was reduced from 0.12 to 0.012 by the addition of fibres.(Figure 11 & 12)

Slope and failure mode: A varying inclining slope and consequently slip at the peak stress appears to be due to measurement scatter. Hence, the stiffness did not appear to be dependent on the fibre content.

The most dominant effect that was observed with the addition of micro reinforcement, was the improved post-peak behaviour. In many cases a sudden drop in load carrying capacity was observed for specimens without any fibre reinforcement right after the peak stress had been reached. This suggests that cracking occurred in the concrete. It appears that the more fibre reinforcement was used the less steep is the declining slope. In other words, the specimens with either type of fibres - PET or steel - were able to carry larger tensile stresses once failure had occurred in comparison to the Reference samples. Fibre reinforcement improved the ductility of the brittle composite material. This was likely due to the well-known crack bridging effect of micro reinforcement. Consequently, the confinement was increased and higher stresses could be transferred at the interface.

PET: The declining slope does not significantly vary between the two fibre contents of 0.1% and 0.2%. It appears that a low PET fibre content of 0.1% led to a notable improvement of the post failure behaviour but a further increase of the amount of synthetic micro reinforcement did not intensify this effect. The effect of the PET fibre content appears to be the most pronounced at an early concrete age. Over the course of 4 weeks, during which the concrete matures, the significance of the influence of the synthetic fibre reinforcement decreased.

Steel: In the case of steel fibre reinforcement however, a fibre content of no more than 0.2% altered the slope pre- and postpeak and a fibre content of 0.5% led to the smallest drop-down of the rebar stress-slip curve. Even though a fibre content of 0.2% already led to a more ductile failure mode, a further increase in steel fibre content led to a further improvement of the post-peak behaviour. The aforementioned improvement became more significant with increasing maturity of the concrete. Hence, the effect of the steel fibres on the post-peak behaviour was more pronounced the higher the fibre content and the more mature the concrete was.

At a concrete maturity of 28 days the steel fibres kept the concrete from splitting due to the crack bridging effect. As a result, pull-out failure rather than splitting failure occurred. A larger amount of metal micro reinforcement led to the specimen to be able to withstand large stresses for a longer period of time. (Figure 13 & 14)

Fracture energy: As mentioned earlier, a more ductile material leads to a shallower softening slope of the bond stress - slip curve. Consequently, the area underneath the aforementioned graph, which represents the unit fracture energy, increases the more ductile the concrete.

In line with the observations regarding the softening slope of the bond stress - slip curve, the unit fracture energy increased with increasing fibre content. This effect appeared to be most significant at an early age.

At an early age of 7 days, the unit fracture energy increased with an increase in fibre volume fraction. This phenomenon was particularly pronounced for the steel fibres. However, it should be noted that the unit fracture energy only appeared to be affected by the fibre volume fraction once the peak load had been reached. Before the peak load was reached, small fibre content (0.1% PET or 0.2% steel) led to an increase in unit fracture energy but a further increase in fibre volume fraction did not increase the unit fracture energy further.

At a concrete maturity of 28 days, 0.1% PET as well as 0.2% steel fibres increased the unit fracture energy. However, a further increase in fibre content did not lead to a significant growth of the unit fracture energy. (Figure 15-17)

Influence of fibre type

Peak bond stress: The steel fibres led to higher peak stresses in comparison to the PET fibres at early concrete ages of 1 and 7 days. At a maturity of 28 days, both fibre types led to the same peak stress. However, the steel fibre reinforced specimens were able to carry the peak stress for a longer period of time in comparison to the PET fibres. This is shown in Figure 17 where the slip increases at a near constant peak load of the S2- VI specimen.

Furthermore, the slip corresponding to the peak stress appeared to be larger for the PET compared to the steel fibres regardless of the concrete maturity.

Slope and failure mode: The metal micro reinforcement caused a steeper inclining slope of the stress-slip curve compared to the synthetic fibres. In other words, only the steel fibres appeared to increase the stiffness.

Furthermore, the sudden loss in load carrying capacity was drastically reduced by both kinds of fibres. Hence, the effect of micro reinforcement on the ductility of the concrete appeared to be improved by both the synthetic as well as the metal fibres. Both fibre types led to pull out failure, whereas the reference specimen failed by splitting.

However, this effect appears to be more pronounced with the addition of steel fibres. At a concrete maturity of 1 day and 28 days the effect of micro reinforcement on the post-peak behaviour was very similar for the two materials. Nonetheless, the synthetic fibres led to a significantly better post-peak behaviour at the age of 7 days in comparison to the metal fibres. (Figure 18-20)

Fracture energy: The unit fracture energy combines the effect of the fibres on the peak bond stress and the slope as it represents the integral of the bond stress slip curve.

The synthetic fibres led to a notable increase of the unit fracture energy in comparison to the Reference specimens at all three testing ages. The effect of the PET fibres on the unit fracture energy increased significantly within the first week as the difference to the Reference specimens rose from 10N/mm to 16N/mm at a slip of 15mm as shown in Figure 18 & 19. However, similarly to the Reference specimens, the unit fracture energy of the PET fibre reinforced samples did not increase further between 7 and 28 days as shown in Figure 19 & 20.

The steel fibres had the same effect as the synthetic fibres on the unit fracture energy at a young age of 1 day. This is shown in Figure 18, where the S2-II and P2-I curves are very close together and lead to an energy increase of 10N/mm at a slip of 15mm compared to the Reference specimens. However, unlike the PET fibres, the steel fibres did not lead to a further increase of the difference in unit fracture energy within the following 6 days. In other words, the gap between the curves of the Reference and the steel fibre reinforced specimen is very similar in Figure 18 & 19. In both cases, the difference between the two curves at a slip of 15mm is approximately 10N/mm. The steel fibre reinforced specimens were the only samples, that experienced a significant increase in unit fracture energy between concrete maturities of 7 and 28 days. The unit fracture energy of the steel fibre reinforced specimens at a slip of 15mm grew by almost 30N/ mm leading to a large gap between the 0.2% Steel FRC and the Reference curve in Figure 20. This observation is in line with the effect of the steel fibres on the peak bond stress as it can carry a large stress for a longer period of time. Consequently, PET fibres led to the largest increase of unit fracture energy at early ages whereas steel fibres are more effective at later ages such as 28 days.

Analytical Model

There are many analytical models describing the bond between rebar and concrete. Bouazaoui & Li [11] proposed a model predicting the interfacial shear stress during pull out tests of cylindrical specimens [11] However, the predicted shear stresses could not be verified by the corresponding experimental study. Yeih et al. [6] developed a model based on a fibre pull out model. The analytical model predicts a load-displacement curve consisting of three stages - linear stage, bend over stage and descending curve - and was verified by an experimental study of cylindrical specimens [6]. The aforementioned study focuses solely on the pull-out failure as this is the expected failure mode under confined conditions [6]. Rostasy & Hartwich [2] took the beneficial effect of fibres into account in their calculations as opposed to the aforementioned models, which do not account for the effect of fibres However, the study focuses on splitting failure and does not investigate other failure modes. Furthermore, it concludes that fibres reinforcement does not have a beneficial effect of the rebar-concrete bond [2], which contradicts the findings of the study at hand. A recent study by Huang et al. [12] used formulas from models of research studies and codes to predict the bond between rebar and concrete under monotonic and cyclic loading. Huang et al. [12] uses a modified version of the fibre factor first introduced by Harajli et al. [4] to incorporate the effect of fibres on the interfacial bond behaviour of rebar in concrete under monotonic load.

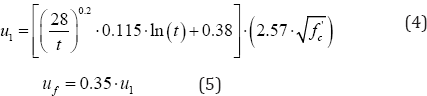

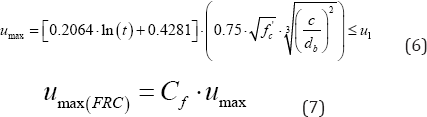

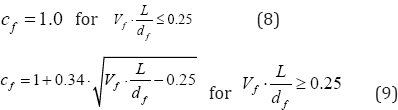

Harajli et al. [4] proposed a bond stress-slip response model in 2002 after conducting a series of indirect flexural pull-out tests [4]. The proposed model was verified by experimental data and it includes the effect of fibres. Furthermore, the model includes the two failure modes splitting and pull out [4]. Within the scope of this project direct pull-out tests were performed as opposed to the indirect or flexural pull-out tests. Furthermore, the type of fibre reinforcement differs. Additionally, the direct pull-out tests were performed at three different concrete maturities of 1 day, 7 days and 28 days. Hence, the analytical model had to be altered in order to fit the test results obtained from the experiments undertaken within the scope of this study. The focus of the modifications lays on the post-peak portion of the curves. A modified version of the bond stress slip model, that requires the 28 day strength fc or specified strength to be known, is time dependent. The parameter t represents the time after casting in days. Eq.(4) through Eq. (12) show the formulas needed to calculate the bond stress at various points of the response curve. With the exception of Eq. (12) the original formulas were not altered but a modification factor or term was added to allow for the influence of concrete maturity and fibre material on the bond strength.

The pull-out bond strength and the following bond strength uf can be calculated with Eq. (4) and Eq. (5) respectively.

Eq. (6) and Eq. (7) determine the local splitting bond strength for plain and fibre reinforced concrete respectively. The aforementioned bond strength is dependent on the ratio between bar cover and bar diameter

The factor Cf that is needed to calculate Umax(FRCu) is dependent on the fibre dimensions and content. It can be determined with Eq. (8) and Eq. (9) where Vf, L and dfsymbolize the fibre volume fraction, length and diameter respectively.

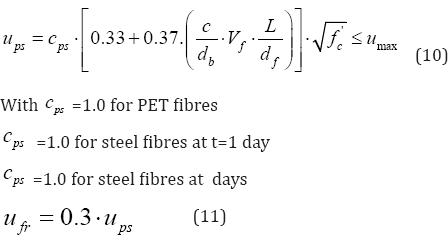

The evaluation of the post splitting bond resistance ups and the following bond strength ufr for FRC is shown in Eq.(10) and Eq.(11).

The descending slope corresponding to the plain concrete after splitting has occurred is described by Eq. (12).

The concrete age t has been added as a parameter that influences the bond strength. Furthermore, the factor cpshas been introduced. This coefficient varies between 1.0 and 2.0 and is dependent on the concrete maturity as well as the fibre material.

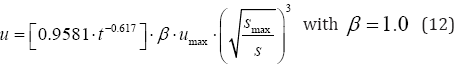

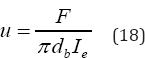

However, the evaluation of the slip cannot be achieved with the Harajli et al. [4]. Not only does the slip appear to be age dependent but it's also influenced by the fibre material and volume fraction as well as the clear distance between the rebar rips. The slip at four different points of the bond stress slip curve can be determined with Eq. (13) through Eq. (17).

By observing the above equations, it becomes apparent that the fibres merely influence the post-peak slip. Therefore, the fibre volume fraction is only introduced as a parameter for the slip calculation in Eq. (15). The parameter Δs is negligible for the concrete ages 1 day and 7 days and can be assumed to be equal to zero. At a concrete maturity of 28 days on the other hand this variable can be substantial. It appears to increase with increasing fibre volume fraction. Furthermore, it can be observed that steel fibres cause a larger Δs compared to PET fibres. Nonetheless, the magnitude of this parameter varies significantly even for identical specimens. Therefore, no formula was derived for the determination of this variable. However, a range for Δs depending on the fibre volume fraction and material can be found in Table 2. (Figure 21)

The curves are simplified and can be evaluated with Eq. (4) through Eq. (17) as well as Table 2. However, the measurement scatter of the pull-out test results is substantial which is why any analytical model - including the one presented here - should be used cautiously.

Comparison of Analytical Model and Experimental Results

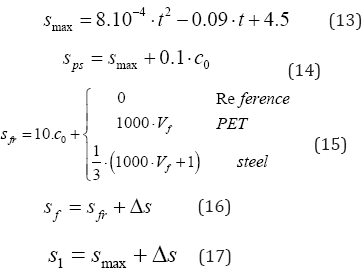

The actual bond stress during the direct pull-out test can be evaluated with Eq. (18). The parameters dbandle denote the bar diameter and the embedment length respectively. The variable F represents the load that is applied to the specimen.

The unit fracture energy represents the integral of the bond stress displacement curve and is approximated by Eq. (19).

The evaluation of the analytical model for plain concrete is shown in Figure 22 in comparison to the experimental data. The response curves that were evaluated with the modified analytical model are shown dashed. A time history of the experimental data in comparison with predicted values for a steel fibre content of 0.5% and a PET fibre content of 0.2 % is shown in Figure 23 & 24. Not only the predicted splitting failure response curve but also the pull-out failure graph is illustrated for the ages of 1 day and 28 days. The dotted graph corresponds to pull-out failure and the dashed graph represents splitting failure.

From Figure 22, it can be observed that the predictions match the experimental data very well. However, the bond strength tends to be overestimated for early ages such as 1 day.

The diagrams in Figure 23 show that the predictions match the experimental data very well. However, the slip at a maturity of 28 days varies significantly as well as the bond stress at an age of 7 days. Therefore, the analytical model should be used with caution in this case.

From Figure 24, it can be observed that the predictions overestimate the bond strength at all three concrete ages. However, the predicted slip matches the experimentally determined displacement very well. Nonetheless, the analytically determined bond strength is similar to the obtained data at maturities of 7 and 28 days.

Summary and Conclusion

The test results show that the fibres led to a more ductile failure during rebar pull-out tests. A small amount of fibres is enough to notably improve the post-peak behaviour by reducing the softening slope of the load carrying capacity. An increase in fibre content beyond a low minimum of 0.1% for PET fibres does not improve the post-failure behaviour any further. However, steel fibres continue to improve the post-peak behaviour when the fibre content is increased from 0.2% to 0.5%. Furthermore, it is observed that the effect of steel fibres is more significant compared to PET fibres and the most pronounced at a high concrete maturity. However, PET fibres led to the most desirable post-peak behaviour at a concrete age of 7 days. Based on the results of this study, a hybrid reinforced specimen with PET and steel fibres might lead to even more desirable test results across a larger range of concrete maturities.

The proposed analytical model appears to match the experimental data well. However, the predicted bond strengths are not always on the safe side. Furthermore, the measurement scatter is fairly substantial for the recorded data of the performed direct pull-out tests. Therefore, analytical predictions of the test results can only reach a certain level of accuracy.

Further research is necessary to determine the influence of the fibre length on the rebar-matrix bond. Additionally, it needs to be investigated if the fibres affect the rebar-matrix bond directly or if they merely improve the ductility of the concrete.

Acknowledgement

The authors would like to thank IC-IMPACTS Centres of Excellence and Natural Sciences and Engineering Research Council (NSERC) for their support throughout this study. Furthermore, the authors would like to thank the laboratory technicians Doug Smith, Harald Schrempp and John Wong for their assistance in conducting the experiments.

References

- Hota S, Naaman AE (1997) Bond stress-slip response of reinforcing bars embedded in FRC matrices under monotonic and cyclic loading. ACI Structural Journal 94(5): 525-537.

- Rostasy FS, Hartwich K (1988) Bond of deformed reinforcing bar embedded in steel fibre reinforced concrete. International Journal of Cement Composites and Lightweight Concrete 10(3): 151-158.

- Dancygier AN, Katz A, Wexler U (2010) Bond between deformed reinforcement and normal and high-strength concrete with and without fibers. Materials and Structures 43(6): 839-856.

- Harajli M, Hamad B, Karam K (2002) Bond-slip Response of Reinforcing Bars Embedded in Plain and Fiber Concrete. Journal of Materials in Civil Engineering 14(6): 503-511.

- Osifala KB, Salau MA, Adeniyi AA (2015) Effect of Waste Plastic Shreds on Bond Resistance between Concrete and Steel Reinforcement. IOP Conference Series: Materials Science and Engineering 96: 12051.

- Yeih W, Huang R, Chang JJ, Yang CC (1997) Pullout test for determining interface properties between rebar and concrete. Advanced Cement Based Materials 5(2): 57-65.

- Machovic V, Andertova J, Kopecky L, Cerny M, Borecka L, et al (2008) Effect of aging of PET fibre on the mechanical properties of PET fibre reinforced cement composite. Ceramics - Silikaty 52(3): 172-182.

- Ochi T, Okubo S, Fukui K (2007) Development of recycled PET fiber and its application as concrete-reinforcing fiber. Cement and Concrete Composites 29(6): 448-455.

- Dai JG, Lam L, Ueda T (2012) Seismic retrofit of square RC columns with polyethylene terephthalate (PET) fibre reinforced polymer composites. Construction and Building Materials 27(1): 206-217.

- Marthong C, Marthong S (2016) An experimental study on the effect of PET fibers on the behavior of exterior RC beam-column connection subjected to reversed cyclic loading. Structures 5: 175-185.

- Bouazaoui L, Li A (2008) Analysis of steel/concrete interfacial shear stress by means of pull out test. International Journal of Adhesion and Adhesives 28(3): 101-108.

- Huang L, Chi Y, Xu L, Chen P, Zhang A (2016) Local bond performance of rebar embedded in steel-polypropylene hybrid fiber reinforced concrete under monotonic and cyclic loading. Construction and Building Materials 103: 77-92.

- Optimet Concrete Products. (n.d.) OPTIMET® STEEL FIBERS.