Stabilization of Expansive Soil Using Industrial Waste: Fly Ash

Mohanty SK*, Pradhan PK and Mohanty CR

Department of civil, Veer Surendra Sai University of Technology, India

Submission: July 10, 2017; Published: January 22, 2018

*Corresponding author: Mohanty SK, Civil Engineering Department, VSSUT, Burla, India, Email: md@smcindia.com

How to cite this article: Mohanty S K, Pradhan P K, Mohanty C R. Stabilization of Expansive Soil Using Industrial Waste: Fly Ash. Civil Eng Res J. 2018; 3(2): 555606. DOI: 10.19080/CERJ.2018.03.555606

Abstract

An experimental investigation is carried out to study the stabilization of locally available expansive soils using fly ash (industrial waste) and lime. Initially fly ash is added to the expansive soils in proportions of ranging from 5% to 30% by weight of dry soils with an increment of 5% and then the geotechnical characteristics such as consistency, swelling, compaction, California bearing ratio (CBR) and consolidation characteristics of stabilized soil are studied. The ideal soil-fly ash mixture with better results is found as soil (70%): fly ash (30%). Then lime is added at low percentages i.e., 1% to 5% to the ideal soil-fly ash mixed sample. The soil-fly ash-lime mixed samples are also tested in the laboratory to determine their above geo-technical properties. For soaked CBR, the soil-fly ash-lime mixed samples are soaked in water for the periods of 4, 7, 14, 21, 28 and 56 days. From the experiment it is revealed that the expansive soils mixed with 30% fly ash and 4% lime gained the maximum CBR value.

Keywords: California bearing ratio; Consolidation; Expansive; Fly ash; Free swell index; Stabilization

Abbreviations: Ground Granulated Blast-Furnace Slag (GGBS), California Bearing Ratio (CBR), Free Swell Index (FSI), Optimum Moisture Content (OMC), Maximum Dry Density (MDD)

Introduction

On wetting, the expansive soil undergoes swelling, resulting in loss of its strength. Further, the expansive soil undergoes shrinking on drying leading to the development of shrinkage cracks. The swell-shrink characteristics of the expansive soil causes the differential movements resulting in severe damage to the foundations, buildings, roads, retaining structures, canal linings, etc. Basically in India, this expansive soil is commonly known as black cotton soil and it covers about 20% of the total land area and extends over number of states including Odisha [1]. So, it has always been a great challenge for geo- technical engineers to improve the characteristics of expansive soil through various innovative and cost effective techniques. Stabilization is one of the techniques among them to improve the geo- technical properties of the expansive soil. Stabilization can be achieved by using different additives. The industrial wastes such as fly ash, dolochar, ground granulated blastfurnace slag (GGBS), lime kiln dust, cement kiln dust, etc are generated from various industries in the state of Odisha. The industries generally dump the industrial wastes in their vicinity causing environmental hazards. Hence, there is an urgent need to explore and exploit the use of the above industrial wastes for minimizing the environmental hazards.

Much research has been done on the fly ash and it has been concluded that fly ash can be a good additive with lime to enhance the engineering properties of expansive soil. JM Kate [2] studied the behaviour of expansive soil treated with lime and fly ash. Sahoo et al. [3] studied the strength characteristics of fly ash mixed with lime stabilized soil. They revealed that the 15% fly ash mixed with 4% lime of the dry weight of soil achieved maximum strength. Recep et al. [4] studied the swelling and strength characteristics of high plastic clay treated with lime and gypsum. They concluded that at 6% lime, the swelling characteristics decreased to 99.55%, swelling pressure decreased to 98.98% and unconfined compressive strength increased to 191.87% at prolong curing. Mohanty et al. studied the stabilization of expansive soil by using fly ash and dolochar.

Similarly, many other researchers like Cocka [5-15], Etim et al. and many others have studied the improvement of various engineering properties of expansive soil with addition of fly ash and lime.

From the review of literature, it is observed that no research work has been done so far in stabilization of the expansive soil of eastern India (state of Odisha) using the local industrial wastes as additives. Hence, in this research an attempt has been made to study the behaviour of locally available expansive soils by using fly ash and lime. This paper reveals that the strength characteristics of locally expansive soil can be increased with the addition of different percentage of fly ash and lime which shown that expansive soil can satisfactorily be used mixed with fly ash and lime for construction of road, pavements, foundation, etc.

Materials Used

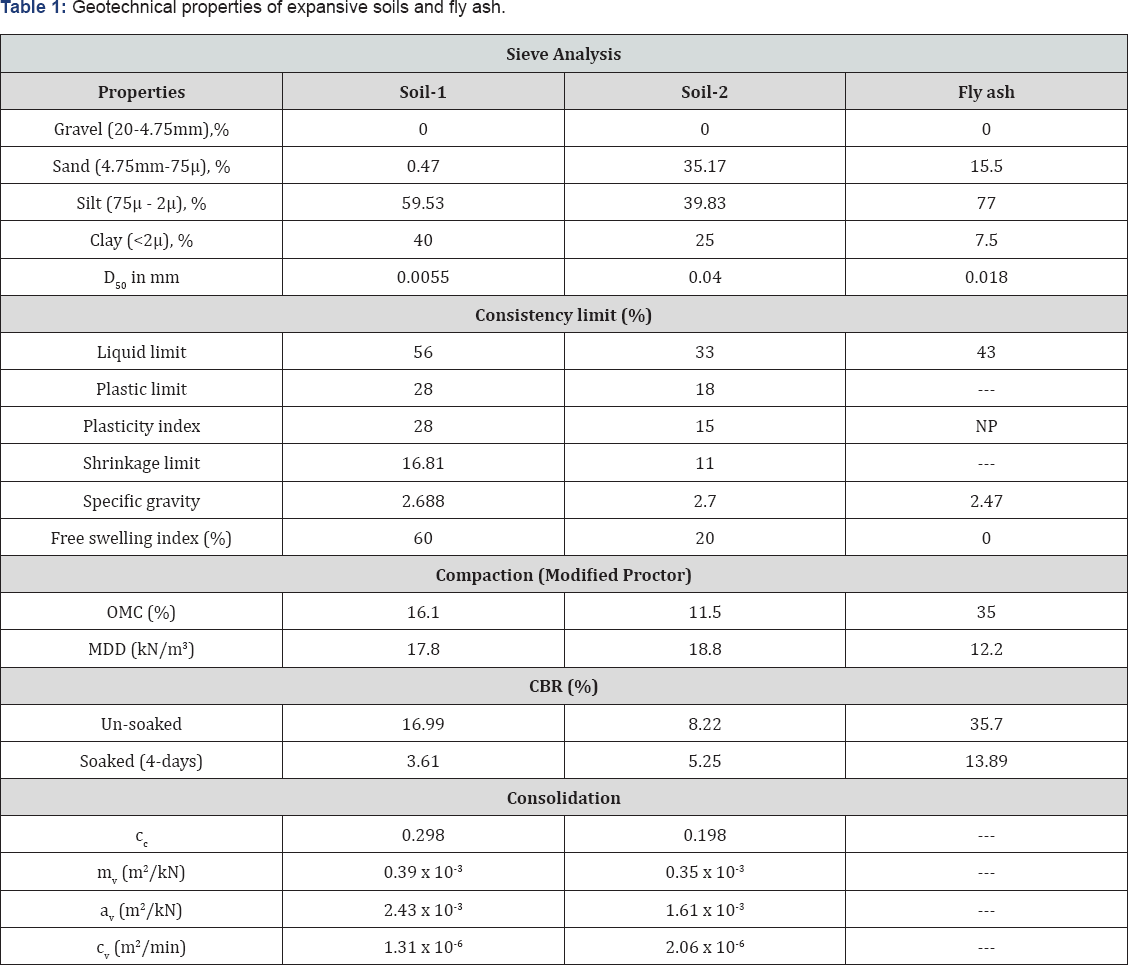

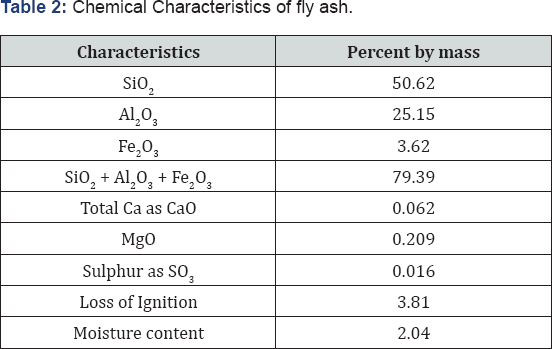

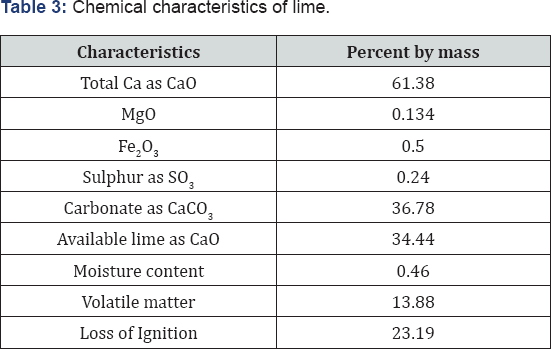

In the present research, two types of local expansive soils are used. One is high expansive soil (soil-1) collected from the Balasore, India and other is low expansive soil (soil-2) collected from the Bhubaneswar, India. The industrial waste i.e., fly ash is collected from the local industry (Birla Tyres Ltd., Balasore, India) and the quick lime is collected from the local market From the laboratory test, the high expansive soil is classified as highly compressible clay (CH), whereas the low expansive soil is classified as low compressible clay (CL). The fly ash used in the experiment is classified as Class F fly ash. The geo-technical properties of soil-1, soil-2 and fly ash are reported in details in Table 1. The chemical analysis of fly ash and lime are presented in Table 2,3 respectively.

Experimental Programme

The virgin materials such as expansive soils, fly ash and lime are kept in hot air oven at 105 °C to dry completely. Then dry soil samples are broken in to small pieces and sieved through 4.75mm IS sieve. The materials which passed through the 4.75mm IS sieve are used for the preparation of soil-fly ash and soil-fly ash -lime samples. Firstly fly ash is added to the expansive soils from 5% to 30% by dry weight of mixed samples with an increment of 5%. Total 12 nos. of soil-fly ash mixed samples is prepared. Then the soil-fly ash mixed Samples are tested in the laboratory to determine their consistency, swelling, compaction, California bearing ratio (CBR) and consolidation characteristics. From the test results, an ideal soil-fly ash mixture with better results is found as soil (70%): fly ash (30%). Then the lime in dry powder form is added to the soil (70%): fly ash (30%) at different percentages, starting from 1% to 5% by dry weight of soil-fly ash mix sample. In this way total 10 nos. of soil-fly ash- lime mixed samples are prepared. The soaked CBR of soil-fly ash samples are determined by soaking the samples in water for 4 days, whereas the soaked CBR of soil-fly ash-lime samples are determined at the soaking periods of 4, 7, 14, 21, 28 and 56 day in water.

Results and Discussion

The geo-technical properties such as consistency, swelling, compaction (OMC and MDD), strength (CBR) and consolidation characteristics of stabilized samples viz, soil-fly ash and soil-fly ash-lime are studied by conducting successive laboratory tests.

Consistency Characteristics

The consistency characteristics of stabilized samples are studied by conducting liquid limit and plastic limit test. It is noticed that the liquid limit and plasticity index of soil-fly ash samples decreased with the increase of fly ash content, whereas the plastic limit of soil-fly ash samples increased with the increase of fly ash content. The decrease of liquid limit may be partly due to the flocculation of soil particles resulting from the cation exchange between the cations contained in the fly ash and the readily exchangeable cations on the soil particle. The increase in silt and sand fractions might have caused the decrease in the soil specific surface area and consequently its water affinity. The consistency limits of soil-fly ash show maximum variation at 30% fly ash content. Then the addition of lime into the soil (70%)-fly ash (30%) samples, the liquid limit, plastic limit and plasticity index decreased. The liquid limit, plastic limit and plasticity index of soil-fly ash-lime samples decreased with the increase of lime content.

Swelling Characteristics

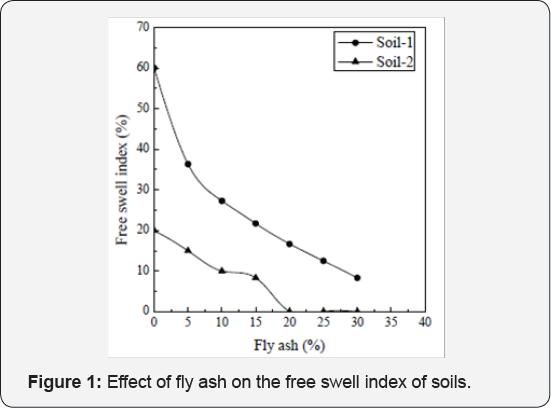

With addition of fly ash to the expansive soils, the free swell index (FSI) of soil-fly ash samples gradually decreased with the increase in fly ash content Figure 1. At 30% fly ash Stabilization of Expansive Soil Using Industrial Waste: Fly Ash content, the FSI of soil-1 of soil-2 is decreased by 86% and 100% as compared to their virgin state. When lime is added to the soil (70%)-fly ash (30%) sample, the FSI gradually decreased with the increase of lime content. Figure 2 shows the variation of FSI of soil-fly ash- lime mixed samples.

Compaction Characteristics

A series of compaction tests are conducted on the soil-fly ash mixed samples. From the test result it is seen that the optimum moisture content (OMC) and maximum dry density (MDD) of soil- fly ash mixed samples are increased and decreased respectively with the increase of fly ash content. The variation of OMC and MDD of soil-fly ash may be due to the following reasons.

o The decrease in MDD with increase in fly ash content is associated with the notion that fly ash is light weight because of its low specific gravity compared to the soils.

o The higher OMC associated with the higher fly ash content as the hydration reaction for cementitious fly ash requires water.

When lime is added to the soil (70%)-fly ash (30%) sample, the OMC and MDD of stabilized samples gradually increased with the increase of lime content. This may be due to the gradually increasing of specific gravity of stabilized soil (soil-fly ash-lime mix) with the increasing of lime content.

Strength Characteristic

California bearing ratio

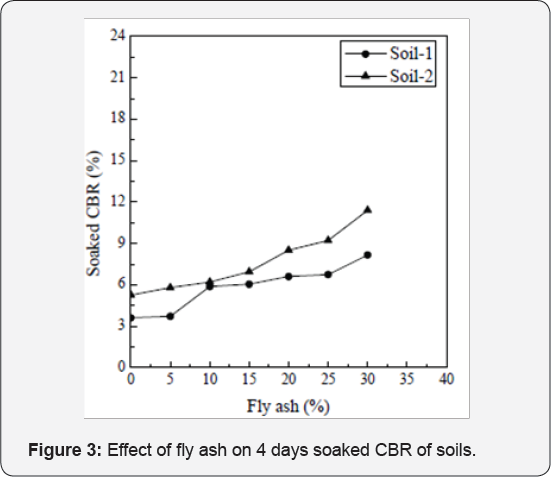

The un-soaked and soaked (4 days soaking) CBR of soil-fly ash mixed samples increased with the increase of fly ash content. Figure 3 shows the effects of fly ash on the 4 days soaked CBR of soil samples. The increase in CBR by the addition of fly ash may be due to the following;

o Flocculation and agglomeration of clay particle take place by the cation exchange reaction in soil-fly ash, resulting granular particles.

o Formation of granular particles increases with the increase of fly ash content At 30% fly ash content, the 4 days soaked CBR of soil-1 and soil-2 increased by 126% and 117% respectively as compared to soil alone.

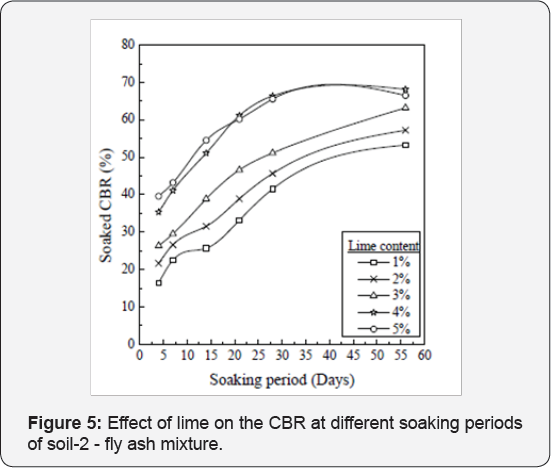

Figure 4,5 show the effect of lime on CBR of soil-fly ash-lime samples of soil-1 and soil-2 respectively at different soaking periods. It is observed that the soaked CBR of soil-fly ash-lime samples are increased with the increase of lime content. It is also noticed that for a given lime content, the soaked CBR of soil-fly ash-lime sample is increased with the increase of soaking period in water. The increase in CBR in presence of lime after prolonged period of soaking may be due the following reasons.

o Pozzolanic reaction in the mixture is favoured due to soaking whereby granular particles are formed due to the presence of fly ash.

o Addition of lime causes the pozzolanic reaction between silica and alumina present in soils and fly ash in the mixed samples under prolonged soaking. The cementing action increases with the increase of lime content in the soil- fly ash-lime mixed sample. The CBR values increased with the increase of lime content. However, after 4% lime content there is no appreciable increase in CBR.

In the present study, the 4 days soaked CBR of soil-1 increased from 3.61 to 29.74% (increased by 724%) by the addition of 30% fly ash and 4% lime, whereas the 4 days soaked CBR of soil- 2 increased from 5.25 to 35.33% (increased by 573%) by the addition of same percentage of fly ash and lime.

Consolidation Characteristics

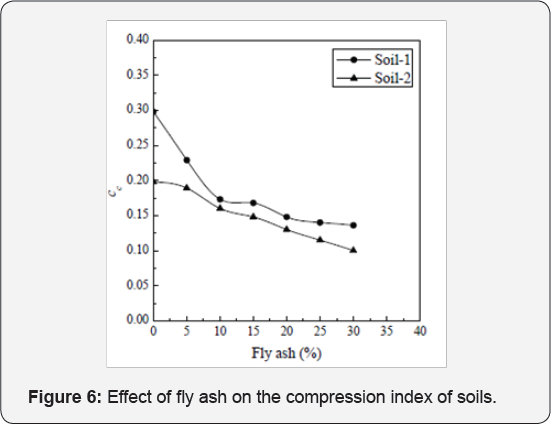

The consolidation characteristics of soil-1 and soil-2 with the addition of fly ash at different percentages are studied by conducting a series of consolidation tests. The compression index (cc), co-efficient of volume change (mv) and co-efficient of compressibility (av) of soil- fly ash mixed samples are decreased with the increase in fly ash content, whereas the co-efficient of consolidation (cv) of soil-fly ash samples increased with the increase of fly ash content. The cause of decrease in the above consolidation parameters may be due to the increase in the flocculation and aggregation caused by the addition of fly ash resulting induced pre-consolidation effect, which increases the vertical effective yield stress and reduces the compressibility characteristics. Figure 6 shows the effect of fly ash on the compression index of soils.

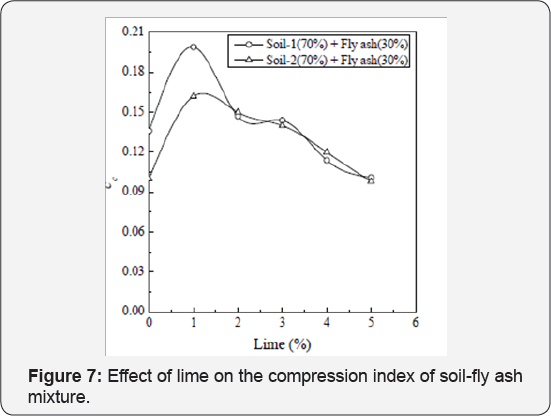

Again, when lime is added to the soil (70%)-fly ash (30%) samples, the compression index (cc), co-efficient of volume change (mv), co-efficient of compressibility (a v) and coefficient of consolidation (cv) of soil-fly ash-lime mixed samples are decreased with the increase in lime content. The decrease of compressibility characteristics of the mixture may be due to the agglomeration formations of soils treated with fly ash and lime, which results in stronger lime particle agglomerates giving higher resistance to compression. Figure 7 shows the effect of lime on the compression index of soil-fly ash samples.

Conclusion

The effect of fly ash and lime on the geo-technical properties of local expansive soils is thoroughly investigated. Based on the results of experimental investigation the following conclusions are drawn.

o With the addition of fly ash, the L.L. and P.I. of soils gradually decreased with the increase of fly ash contents. Maximum decrease is being observed at 30% fly ash content. Also, the addition of lime to the soil-fly ash mixture reduced the L.L. and P.I. further.

o Addition of fly ash decreased the FSI of soils, maximum Decrease is being observed at fly ash content of 30%. Stabilization of Expansive Soil Using Industrial Waste: Fly Ash Addition of lime to the above mixture reduced the FSI further. The FSI of soil-1 and soil-2 with 30% fly ash and 4% lime content are reduced by 100%.

o The OMC and MDD of soil-fly ash mixed samples are increased and decreased respectively with the increase of fly ash content. However, with the addition of lime in to the soil (70%)-fly ash (30%) mixed samples, the OMC and MDD gradually increased with the increase of lime content.

o CBR of soil-fly ash mixed samples is increased with the increase of fly ash content. The maximum increase is being observed at 30% fly ash content. At 30% fly ash content, the 4 days soaked CBR of soil-1 and soil-2 is increased by 126% and 117% respectively. Again the soaked CBR of stabilized soils with 30% fly ash increased further with increase in lime content, the maximum increase is being observed at 4% lime content. Also, for a given lime content, the CBR values of soil-fly ash-lime are increased with the increase of soaking periods. With 30% fly ash and 4% lime content, the 4-days soaked CBR of soil-1 and soil-2 increase by 724% and 573% respectively as compared to parent soils.

o With the increase of fly ash content, the compression index (cc), co-efficient of volume change (mv) and co-efficient of compressibility (av) of the mixture soils decreased and co-efficient of consolidation (cv) increased. With addition of lime all the above parameters decreased.

o The optimum mixture design proportion of soil-fly ash- lime is found to be 70:30:04 for the materials i.e., soils, fly ash, dolochar, lime, etc taken for the studies in this case.

o Stabilization by addition of fly ash with or without lime is found to be more effective in case of highly expansive soil.

o Addition of 30% fly ash with 4% lime will definitely improve the local expansive soil for sustainable use in the construction of roads, pavements and foundations which will reduce the cost of construction and disposal problem of industrial wastes which otherwise lead to environmental hazards.

References

- Katti RK (1979) Search for solutions to problems in black cotton soils, First TGS annual lecture. Indian Geotech Journal.

- Kate JM (2009) Behavior of Expansive Clays Treated with Lime Fly Ash Admixtures, In Proc. Indian Geotechnical Conference, Guntur, India.

- Sahoo JP, Sahoo S, Yadav VK (2010) Strength Characteristics of Fly Ash Mixed With Lime Stabilized Soil, Indian Geotechnical Conference, Mumbai, India.

- Recep K, Ozgur K, Koray U (2015) Stabilization of high expansive clay with lime and gypsum (Ankara, Turkey) Bull Eng Geol Environ- Springer.

- Cokca E (2001) Use of class C fly ashes for the stabilization-of an expansive soil. Journal of Geotechnical and Geo environmental Engineering 127(7): 568-573.

- Edil TB, Acosta, HA, Benson CH (2006) Stabilizing soft fine grained soils with fly ash. Journal of Materials in Civil Engineering. ASCE 18(2): 283-294.

- Bera AK, Ghosh A (2007) Compaction characteristics of pond ash (ASCE) 19 (4): 349-357.

- Sharma R, Phanikumar B, Rao B (2008) Engineering Behavior of Remolded Expansive Clay Blended with Lime, Calcium Chloride and Rice-Husk Ash. Journal of Materials in Civil Engineering 20(8): 509.

- Solanki P. Khoury N, Zaman M (2009) Engineering Properties and Moisture Susceptibility of Silty Clay Stabilized with Lime, Class C Fly Ash, and Cement Kiln Dust 21(12): 749-757.

- Brooks R, Udoeyo F, Takkalapelli K (2010) Geotechnical Properties of Problem Soils Stabilized with Fly Ash and Limestone Dust in Philadelphia. Journal of Materials in Civil Engineering 23(5): 711-716.

- Seco A, Ramirez F, Miqueleiz L, Garcia B (2011) Stabilization of expansive soils for use in construction. Applied Clay Science 51(3): 348-352.

- Bose B (2012) Geo-engineering properties of expansive soil stabilized with fly ash, Electronic journal of geotechnical engineering 17: 13391353.

- Singh B, Goswami R (2012) Compaction characteristics of lateritic soil mixed with fly ash and lime. International Journal of Geotechnical Engineering 6(4): 437-444.

- Mir BA, Sridharan A (2014) Volume change behaviour of clayey soil-fly ash mixtures, International Journal of Geotechnical Engineering 8(1): 72-83.

- Kang X, Ge L, Kang G, Mathews C (2015) Laboratory investigation of the strength, stiffness, and thermal conductivity of fly ash and lime kiln dust stabilised clay sub grade materials, Road Materials and Pavement Design 16(4): 928-945.