Critical Review of the Greenhouse Gas and Environmental Impact of Common Materials in Civil and Construction Projects: Present and Alternatives

MCP Sing1* and DJ Edwards2

1Department of Building and Real Estate, Hong Kong Polytechnic University, Hong Kong

2Department of Engineering and the Built Environment, Birmingham City University, UK

Submission: September 21, 2017; Published: October 13, 2017

*Corresponding author: Michael Sing, Department of Building and Real Estate, The Hong Kong Polytechnic University, Hung Hom, Hong Kong, Tel: +852 3400 8117; Fax: +852 2766 5884; Email: mcpsing@outlook.com

How to cite this article: M Sing, D Edwards. Critical Review of the Greenhouse Gas and Environmental Impact of Common Materials in Civil and Construction Projects: Present and Alternatives. Civil Eng Res J. 2017; 1(5): 555594. DOI: 10.19080/CERJ.2017.02.555594

Abstract

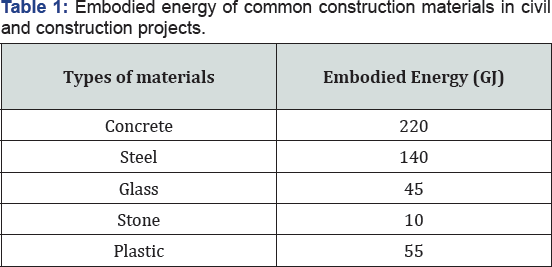

Climate change due to the greenhouse gas emissions from anthropogenic and natural activities has become a major concern internationally. The civil and construction sectors have been identified as one of the major contributors of global environmental impact due to their high- energy consumption. Embodied energy is used to provide a full picture of the energy consumption of the materials from the extraction and deconstruction. This paper is to conduct a critical review of a high-embodied energy artificial mixture, concrete, one of the most commonly used materials in construction industry and suggest the latest practices to minimize the adverse impacts of its application in civil and construction project.

Keywords: Environmental impact; Embodied energy; Concrete; Life cycle

Introduction

Climate change due to the greenhouse gas emissions from anthropogenic and natural activities has become a major concern internationally. Rapid urbanization, continuous industrialization and improved living standards have inflated energy consumption in recent years. Construction works require vast quantities of materials and the consumption of virgin resources, and this releases deleterious pollutant emission to the biosphere. Globally, the construction industry produces high levels of pollution energy consumed (and concomitant greenhouse gas emission) during extraction, processing and transportation of raw materials. For example, the energy used to manufacture and transport construction materials represents nearly 10-15% of all primary energy used in developed countries such as the United Kingdom, whereas 50% of all energy consumed is attributable to the operational stage of the buildings/ assets Thormark [1]. The embodied energy aims to measure the total energy necessary for an entire product (or material) life-cycle that is, extraction, production, transportation, installation and deconstruction/ decomposition. The use of high embodied energy materials such as concrete, cement and aluminum, must comply with the environmental friendly material concept. Opportunities to reduce embodied energy and greenhouse gas emissions occur during at various stages of the building's life cycle, namely: (a) design, (b) construction and (c) operation stages. This paper seeks to conduct a critical review of high embodied energy and greenhouse gas emissions of the construction material 'concrete' and suggest the latest practices to minimize the adverse impact of its application in civil engineering and construction projects.

Reinforced concrete

For civil engineering and construction projects, reinforced concrete is a common 'composite' construction material that is stronger, durable and less likely to fail under load CSIRO [2]. Reducing embodied energy used in concrete can play a significant role in achieving sustainable construction.

Design stage: In the design stage, adjusting traditional concrete mixtures can decrease the embodied energy. Tosic et al. [3] stated that post-tensioned slabs induced less embodied energy than traditional reinforced concrete slabs. The adoption of fly ash in replacing traditional cement elements can also help to reduce embodied energy inherent within concrete. Portland cement can be replaced with less carbon-intensive materials such as Pulverized Fuel Ash (PFA) and Ground Granulated Blast furnace Slag (GGBS). PFA can replace up to 40% of cement in typical construction and engineering applications Hammond & Jones [4]. A filler slab is another option for reducing the weight of structural elements, which are solid reinforced concrete slabs with partial replacement of the concrete in the tension zone by a filler material. Lightweight and inert such as low-grade Mangalore tiles, Thermopolis Burnt Clay Bricks, hollow concrete blocks, stabilized mud blocks can be used as filler materials Reddy & Jagadish [5]. At least 30% of concrete is saved using the filler slab technique.

Construction stage: Transportation is a major contributor to the embodied energy of construction materials. A concrete truck normally emits not less than 100x10-6kg of carbon dioxide for transporting each kg of concrete over one km distance. The emission is increased if small trucks or Lorries are used. Using locally sourced materials will reduce the embodied energy during the construction stage by reducing carbon emissions from transportation. Locally sourced materials also include materials salvaged on site. Concrete can be recycled as an aggregate after the demolition of existing buildings. Under the strict control of the recycled aggregate, it can be used to replace part of the natural aggregate Tosic et al. [3] and can minimize the transportation of natural aggregate from overseas.

Operational stage: During the operational stage, keeping regular maintenance can effectively enhance the lifespan of the building's structural elements. Proper maintenance to minor concrete defects should be carried out as soon as possible once defects are identified. For example, using spraying concrete techniques for repairing the defective concrete can provide a high density and low permeability cover to the existing concrete structure Sprayed Concrete Association [6]. When compared to demolition and reconstruction, a vast amount of raw material (such as cement) can be saved, thus reducing embodied energy.

Conclusions

The civil and construction sectors have been identified as one of the major contributors of global environmental impact due to their high-energy consumption. Reducing embodied energy in construction materials through recycling and reuse of materials, balancing the use of the materials and proper maintenance to the structural elements can make a considerable improvement to the energy use during the lifecycle of civil engineering and construction projects.

References

- Thormark C (2002) A low energy building in a life cycle-its embodied energy, energy need for operation and recycling potential. Building and environment 37(4): 429-435.

- CSIRO (2000) Embodied and Life Time Energies in the Built Environment.

- Toşíć N, Marinkovic S, Daşíć T, Stanşíć M (2015) Multicriteria optimization of natural and recycled aggregate concrete for structural use. Journal of Cleaner Production 87: 766-776.

- Hammond GP, Jones CI (2008) Embodied energy and carbon in construction materials. Proceedings of the Institution of Civil Engineers-Energy 161(2): 87-98.

- Reddy BV, Jagadish K (2003) Embodied energy of common and alternative building materials and technologies. Energy and buildings 35(2): 129-137.

- Sprayed Concrete Association (1999) Introduction to Sprayed Concrete.