Surface Energy Modifications of Printable Flexible Electronics Substrates Using Plasma- and Laser-Based Processing

Mohamad Taherian and Martin Bolduc*

Université du Québec à Trois Rivières, Trois Rivières, Québec, Canada

Submission: September 13, 2024; Published: October 04, 2024

*Corresponding author: Martin Bolduc, Université du Québec à Trois Rivières, Trois Rivières, Québec, Canada

How to cite this article: Mohamad Taherian and Martin Bolduc*. Surface Energy Modifications of Printable Flexible Electronics Substrates Using Plasma- and Laser-Based Processing. Academ J Polym Sci. 2024; 6(4): 555689. DOI: 10.19080/AJOP.2024.06.555689

Abstract

In this study, surface modification of Kapton and PET flexible substrates for printed electronics has been conducted under extensive analysis. Two primary methods, namely laser processing and plasma treatment, have been used with the aim of improving surface wettability to increase printability of metallic ink materials. To evaluate these treatments, we carried out experiments to measure contact angles, where plasma and laser treatment have produced significant changes in the contact angle. Our research highlights the differing effects of plasma and laser treatments on Kapton surfaces, offering valuable insights to researchers and practitioners in the printed electronics field. This study emphasizes the importance of precise control over treatment parameters and a deep understanding of the techniques, allowing for tailored surface modifications to meet the specific needs of electronic applications.

Keywords: Surface Energy; Contact Angle; Printed Electronics; Plasma Treatment; Laser Processing; Kapton Flexible Substrates

Introduction

The surface properties of flexible substrates play a critical role in printed electronics applications [1-3]. Different modification techniques have been extensively studied. Some of these modifications change surface through chemical changes such as increasing free radicals of the surface [4]. Laser treatment allows for localized alteration of the substrate, offering exceptional control over the specific areas that require modification [5]. This precise targeting ensures that only the intended regions undergo changes in roughness, energy, or topography. The non-contact nature of laser treatment also reduces the risk of mechanical damage to the substrate. Furthermore, the process can lead to enhanced adhesion and improved print quality, particularly by creating microstructures that facilitate ink adhesion. However, the effectiveness of laser treatment can be influenced by factors such as the material’s thermal properties, potentially leading to unintended changes in material characteristics due to heat effects. While laser surface modification holds immense promise in tailoring surfaces for specific applications, the investment required and potential material alterations remain challenges to consider in its adoption [6-7]. Plasma treatment, a powerful surface modification technique, involves subjecting materials to low-temperature plasma within a vacuum chamber [8]. Recent studies have shed light on its advantages and limitations. Notably, plasma treatment significantly enhances adhesion by promoting better bonding with coatings, paints, and adhesives by increasing the material’s surface energy, making it more receptive to external agents [9]. Additionally, plasma treatment ensures surface cleanliness by removing contaminants. Environmentally friendly and devoid of harsh chemicals, it offers a sustainable alternative for surface modification [10]. However, one limitation lies in its narrow treating width, which may hinder efficient treatment of large areas [8]. For optimizing surface properties to enhance printing substrates, two distinct methods were chosen: plasma treatment and laser processing. These techniques offer diverse avenues for modifying surface characteristics.

Materials and Methods

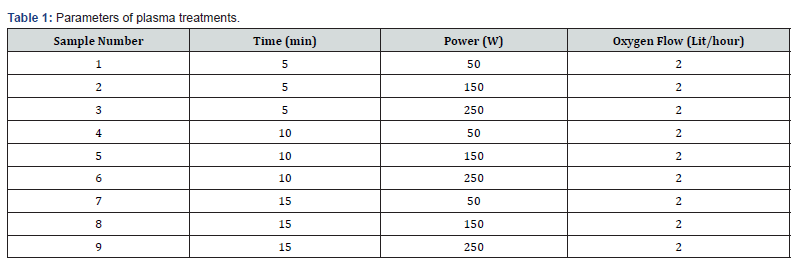

The evaluation of surface modifications involved the assessment of contact angle (Holmarc device, Contact angle meter as the software) and the examination of microscopic images of the treated samples (SEM Hitachi SU8230 & Laser Confocal Microscope LEXT4100). The first part of our study is the surface modification of Kapton by plasma treatment using Plasma Therm Unaxis 790 Plasma Etch system. Different plasma powers were utilized to understand their impact on Kapton surface properties. A total of 9 samples were prepared, which is summarized in the following table. After the plasma treatment, contact angle measurements were performed.

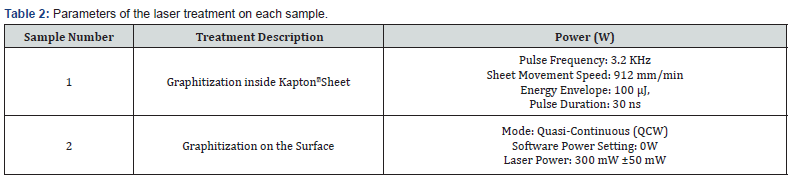

The second method was the application of MOPAW (Master Oscillator Programmable Amplitude Waveform) laser technology from the Institut National d’Optique (INO, Canada) and emits at a 1064 nm wavelength. The first sample was treated through graphitization within the KaptonÒ sheet, which was executed in two passes of the laser, initially in the X direction and subsequently in the Y direction. These parameters insured an overlap of approximately 50%. The laser operated at a pulse frequency of 3.2 KHz, while the sheet moved at a speed of 912 mm/min. This process utilized a 100-microjoule energy envelope characterized by a pulse duration of 30 nanoseconds and a distinctive inverted ‘chair’ shape. Also, the optical setup at the exit of the MOPAW laser has an opto-isolator which reduces the target receive intensity by 40%. For the second sample, after the completion of the first step, the second step was done involving the graphitization of the surface, resulting in the creation of the grey/dark square area. It employed the Quasi-Continuous (QCW) mode of the laser, operating with a power setting of 0W in the software. In practical terms, the laser emitted at a minimum of approximately 300 mW, with minor fluctuations of around +/- 50 mW. The following table provides a concise summary of the key parameters for each laser treatment step, aiding in the clear representation of your experimental process.

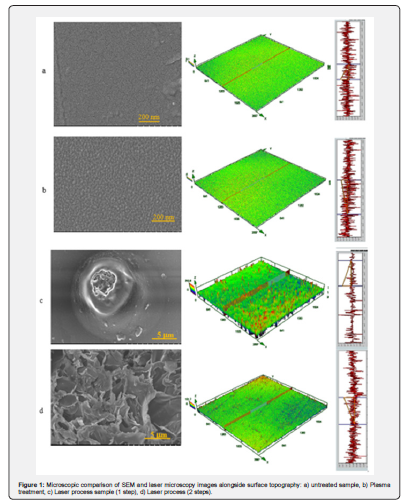

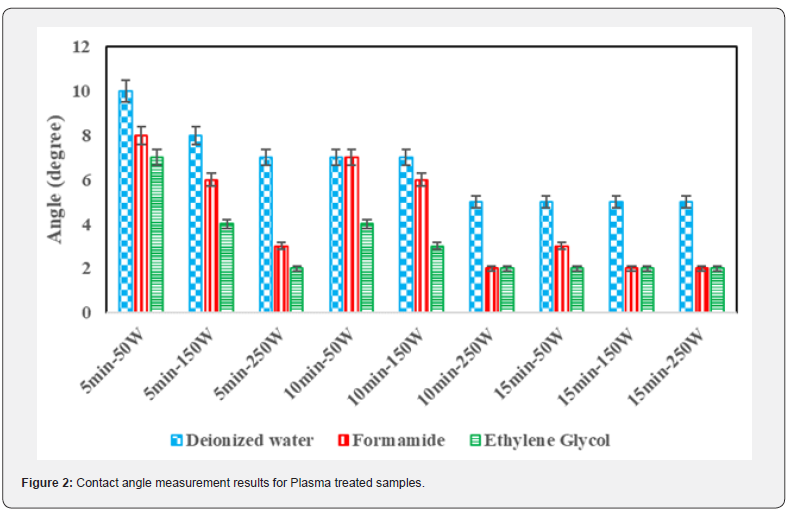

While there were no discernible physical changes in the surface morphology of plasma treated samples, a significant shift in contact angle was observed. In the diagram (Figure 2), contact angles are observed to be higher with lower power and shorter treatment durations, resulting in lower surface energy values. However, as both treatment time and power are increased, a critical point is reached where the surface energy stabilizes, demonstrating no further increase Therefore the optimal conditions for this treatment were determined to be at 10 mins with 250W.

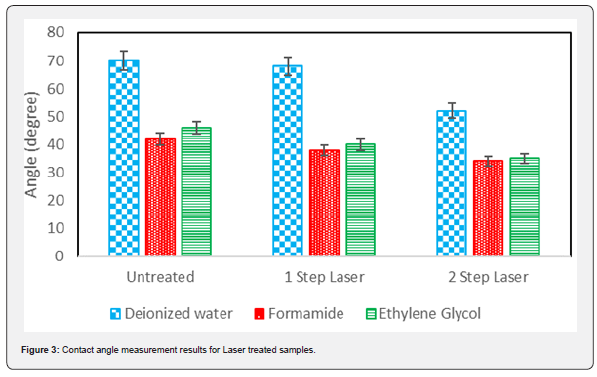

On the other hand, Laser treatment exhibited a notable influence on the samples; however, the effects for one step lasered sample manifested below the surface. Intriguingly, contact angle exhibited minimal alterations (Figure 3). This observation was further corroborated by the SEM and laser microscopy images, which depicted minimum surface changes.

Discussion

Lower contact angle for plasma treated samples can be attributed to the chemical transformations induced by the plasma treatment [11]. Even in the absence of evident alterations at the macroscopic level, the energetic interactions at the surface underwent a remarkable shift due to chemical functionalization [12]. In the realm of plasma treatment, the interaction between ozone molecules and the end terminations of the polyimide chain plays a pivotal role in surface modification. This intricate process involves the activation and subsequent chemical modification of the polyimide surface, influencing its wettability and adhesion properties. Notably, studies investigate the nuanced mechanisms underlying ozone interaction with polyimide, shedding light on the chemical transformations and surface enhancements induced by this treatment [13-14].

The increase in surface energy observed in the high-energy plasma-treated samples was attributed to the formation of free radicals and the disruption of chemical bonds on the surface of the KaptonÒ.These chemical changes resulted in enhanced surface energy. Consequently, this chemical modification, rather than physical alteration, played a pivotal role in the transformation of surface energy, a crucial finding for applications that rely on surface wettability and adhesion. As it was mentioned, by increasing time and temperature beyond a certain point, contact angle does not decrease any more. This equilibrium level signifies that a saturation point is reached, where the surface has accommodated an optimal concentration of free radicals. Beyond this point, additional surface bonds are no longer available for the generation of free radicals, which is a crucial factor in influencing surface energy. It is evident that the laser treatment primarily induced subsurface alterations, leaving the surface properties of the sample relatively unaffected. These findings emphasize the importance comprehending the depth and extent of surface modifications when employing laser treatment techniques, particularly in applications where surface characteristics are critical. As mentioned earlier, each of the laser-treated samples exhibited different characteristics, consequently yielding markedly dissimilar results. In the case of the single-step sample, the initial treatment involved graphitization within the material, while for the dual-step sample, this graphitization occurred in the subsequent step after the initial treatment. This sequencing discrepancy led to a substantial variance in surface properties between the two samples. The accompanying diagram illustrates the contact angle measurements for both the single-step and dualstep treated samples in comparison to the untreated sample. As anticipated, the two-step treated sample exhibited a noticeably rougher surface than its single-step counterpart, which in turn resulted in a lower contact angle.

Conclusion

Laser treatment resulted in a noticeable 28% decrease in contact angle of surface with DI water. However, the most significant increase in surface changes was observed with plasma treatment, showing more than 90% change in contact angle of surface with DI water compared to untreated sample. However, an intriguing saturation point suggests careful consideration of treatment time and power, as further increments yielded minimal additional enhancement. Plasma treatment emerges as a powerful method, considering overall changes and the delicate balance between time and enhancement goals.

References

- Hewitt GF, Delhaye JM, N Zuber (2013) Multiphase Science and Technology. Volume 2, Springer Science & Business Media.

- Bousfield, DW (2001) Progress in Organic Coatings. 41(1-3): 51-58.

- M Bolduc, C Trudeau, SG Cloutier, P Galarneau (2018) Thermal Dynamics Effects using Pulse-Shaping Laser Sintering of Printed Silver Inks. Scientific Report 8(1).

- W Sun, W Liu, Z Wu, H Chen (2020) Chemical Surface Modification of Polymeric Biomaterials for Biomedical Applications. Macromolecular Rapid Communications Volume 41(8): 1900430.

- Y Okamoto, YUno, T Mohri, T Izawa (2009) Investigation of Surface Treatment Method by High-Speed Scanning of Single-Mode Fiber Laser with MOPA. Key Engineering Materials volume 407-408: 624.

- B Szubzda (2016) IOP Conf. Ser. Sci. Eng., volume113(1): 012017.

- SS Ham and H Lee (2020) Surface Characteristics of Polymers with Different Absorbance after UV Picosecond Pulsed Laser Processing Using Various Repetition Rates. Polymers volume 12(9).

- A Waskow, A Howling (2021) Advantages and Limitations of Surface Analysis Techniques onPlasma-Treated Arabidopsis thaliana Seeds. I Furno volume (8).

- A Paproth, KJ Wolter, T Zerna (2001) IEEE Conference Proceedings, p. 37.

- K K Samanta, S Basak, S K Chattopadhyay (2014) Environment-Friendly Textile Processing Using Plasma and UV Treatment. Edition in Textile Science and Clothing Technology Singapore: Springer, pp. 161-201.

- XH Zhao, ZG Shen, YS Xing, SL Ma (2001) J Phys. Appl. Phys., volume 34: 2308.

- N Inagaki, S Tasaka, K Hibi, J Polym (1992) Sci Part Polym Chem volume (30): 1425.

- T Kondo, R Watanabe, Y Shimoyama, K Shinohe, S A Kulinich et al. (2017) Surf Interface Anal volume (49): 1069.

- FD Egitto, LJ Matienzo, AR Knoll, J Adhes (1994) Sci Technol volume (8): 411.