A Comparative Study of Multiwalled Carbon Nanotube Based Polystyrene and Toughened Polycarbonate Nanocomposites

Nisha Bagotia* and Sharma DK

Centre for Energy Studies, Indian Institute of Technology Delhi, India

Submission: July 09, 2018; Published: July 17, 2018

*Corresponding author: Centre for Energy Studies, Indian Institute of Technology Delhi, India Tel: +91-11-206591256;Email: nshnnl46@gmail.com

How to cite this article: Nisha B,Sharma DK. A Comparative Study of Multiwalled Carbon Nanotube Based Polystyrene and Toughened Polycarbonate Nanocomposites. Academ J Polym Sci. 2018; 1(3): 555561. DOI: 10.19080/AJOP.2018.01.555561

Abstract

The main objective of this article is to describe the effect of different length (aspect ratio) of carbon nanotubes (CNTs) on the electrical conductivity and electromagnetic shielding effectiveness of polystyrene/l-MWCNT and toughened polycarbonate/s-MWCNT composites. Long and short MWCNTs having aspect ratio of ~666 - 1333 and ~157 respectively were used for melt-mixed with polystyrene and toughened polycarbonate in a micro compounder. The uniform dispersion of MWCNT in matrix was confirmed by scanning electron microscopy. The realization shielding effectiveness value of -21dB respectively for PS/l-MWCNT composites: and -27dB for TPC/s-MWCNT composites at 10phr loading of MWCNTs, which show their potential use in making of mechanically strong and light weight EMI shield used for commercial application.

Keywords: Polycarbonate; Polystyrene; Multiwalled carbon nanotube; Electrical properties; EMI shielding effectiveness

Abbrevations: Carbon Nanotubes; EC: Electrical Conductivity; EMI: Electromagnetic Interference; l-MWCNTs: Long Length Multiwalled Carbon Nanotubes; PC: Polycarbonate; PS: Polystyrene; PTT: Poly(trimethylene terephthalate); SE: Shielding Effectiveness; SEM: Scanning Electron Microscope; s-MWCNTs: Small Length multiwalled carbon nanotubes; s-MWCNTs: Small Multiwalled Carbon Nanotubes; SWCNTs: Single Walled Carbon Nanotubes; TEM: Transmission Electron Microscope; TPC: Toughened Polycarbonate; VNA: Vector Network Analyzer

Introduction

The broad developments of electronic systems and telecommunications has led to a novel type of pollution i.e. electromagnetic interference (EMI). EMI has appeared as a major problem, which not only affecting the proper working of electronic devices but as well as causing harmful effects to the health of human beings [1,2]. Generally, mobile phone, radar, radio transceivers, microwave oven, and various electronic devices are the main causes of EMI [3,4]. The long time exposure of EM waves have also been recognized as strong cancer-causing agent [5]. Therefore, appropriate shield is required to reduce the effect of EM waves. Generally, electrically conductive or magnetic filler are used as a EMI shielding material, because these materials have capability to interact with coupled electric and magnetic fields of the incident EM waves [6,7]. Metals and metal loaded composites have been widely used as EMI shielding materials, but these materials have disadvantages such as high density, corrosion prone, inconvenient processing etc. which limits their practical applicability. As compare to the metals, carbon nanomaterials have appeared as promising alternative conductive filler for production of EMI shield [6,8,9].

Nowadays, the use of carbon nanotubes (CNTs), having ultra-high modulus and strength, good thermal and electrical properties, as filler in polymer nanocomposites prepare material with lower filler loadings having improved electrical and EMI shielding properties [10-15]. As reported in literature, mechanical strength, electrical conductivity or thermal properties and EMI shielding effectiveness of the polymer nanocomposites are affected by different factors such as the aspect ratio, dispersion, processing methods, treatment methods, and loading of CNTs [16]. Li et al. [15] studied the conductivity and EMI SE of epoxy/SWCNT nanocomposites filled with SWCNTs having different aspect ratios. The maximum EMI shielding effectiveness has been reported for epoxy/SWCNT composites having 15wt% SWCNTs-long (SE ∼49dB and 15-20dB obtained at 10MHz and in the 500MHz to 1.5GHz range respectively). In another study, Gupta et al. [17] reported EMI shielding properties (in Ku-band) of poly (trimethylene terephthalate) (PTT)/MWCNT nanocomposites. Electrical percolation of composites has been reported at 1wt% loading of MWCNT and SE of 36-42dB reported at 10wt% loading of MWCNT. Bai et al. [18] described the effect of nanotube aspect ratio on the electrical properties and mechanical strength of the epoxy/MWCNT nanocomposites using three different length ofMWCNTs (~1,10,50μm). It has been found that the short lengthMWCNTs (10μm) report good mechanical properties whilelong length MWCNTs (50μm) improved electrical properties ofnanocomposites. Singh et al. [19] investigated the effect of CNTshaving different aspect ratio on the electrical, mechanical andEMI shielding properties of epoxy/CNTs nanocomposites atlow loading of CNT (0.5wt%). It has been observed that highaspect ratio CNTs filled nanocomposites show higher electrical(percolation threshold at 0.02wt% loading of l-MWCNT),mechanical (125MPa at 0.3wt% loading of l-MWCNT) and EMIshielding properties (highest SE ~16dB) in comparison to thosefilled with lower aspect ratio MWCNTs (percolation threshold at0.11wt%, flexural strength -113MPa at 0.3wt% and maximumshielding of ~11dB). Huang et al. [20] investigated the effectof heat treatment and CNTs with different aspect ratio on theEMI shielding effectiveness of epoxy/SWCNT nanocomposites(up to 15wt% SWCNTs). They reported that long SWCNTs basednanocomposites give high EMI SE (SE ~3 to 28dB) as comparedto short annealed SWCNTs (SE ~21-23dB) and unannealedshort SWCNTs (SE ~17-18dB). Al-Guo et al. [21] studied theeffects of MWCNTs with high aspect ratio (313 and 474) on theelectrical, mechanical, and thermal properties of PC/MWCNTnanocomposites. Above mentioned literature showed that mostof studies either show EMI shielding effectiveness or mechanicalproperties of different types of MWCNTs based nanocompositesunder higher loading of CNTs; or with both mechanical andEMI properties under lower loading of CNTs. Therefore, acomparative study of the preparation of higher loaded MWCNTnanocomposites and describing the effect of aspect ratio ofMWCNTs on the mechanical, electrical and EMI shieldingproperties, of polymer nanocomposites is necessary.

The main objective of this paper to describe the effect ofaspect ratio of MWCNTs on the electrical and EMI shieldingproperties of MWCNT based polystyrene (PS) and toughenedpolycarbonate (TPC) composites containing up to 10phrMWCNTs. The nanocomposites have been prepared by meltcompounding of PS and TPC with MWCNTs in a twin screwmicro-compounder. Two types of MWCNTs viz. long (l-MWCNT)having diameter ~7.5nm & length ~5-10μm (aspect ratio ~666-1333) and short (s-MWCNTs) having diameter 9.5nm & length~1.5μm (aspect ratio ~157) were used for the fabricationof nanocomposites. The dispersion of MWCNTs in matrix isinvestigated by scanning electron microscopy. The EMI shieldingof nanocomposites was measured in X-band (frequency range of8.2-12.4GHz). The morphology, electrical conductivity and EMIshielding effectiveness of composites have been interrelatedwith distribution density and aspect ratio of CNTs, under bothlower and higher loading.

Materials and Methods

Materials

Polystyrene (SC206) was purchased from SupremePetrochem limited. Polycarbonate (PC) Lexan 143, procuredfrom Sabic Innovative Plastic. Ethylene methyl acrylate (EMA)copolymer (Elvaloy® AC 1330 from DuPont) having 70% byweight ethylene and 30% by weight methyl acrylate are used inthis investigation for toughening of PC [22,23]. Here, 5wt% EMAcontaining PC (TPC) is used for study. The long length MWCNTs(l-MWCNTs) were produced by CVD method using pongamia oilas a carbon source and ferrocene as catalyst and preparationprocess is mentioned elsewhere [24]. The diameter of l-MWCNT was in the range of 50-200nm and length is in the range 5-10μm.The short length MWCNTs (s-MWCNTs), grade NC7000 with90% carbon purity (length ~1.5μm and diameter ~9.5nm) wereobtained from Nanocyl, Belgium.

Methods

Fabrication of PS/MWCNT and TPC/MWCNT nanocomposites

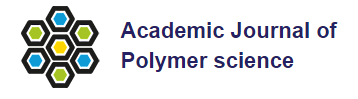

The melt blending approach for fabrication of PS/l-MWCNTand TPC/s-MWCNT composites was used in this study. Dryingof PS, TPC and MWCNTs was performed before melt blendingfor 24 h at 70 °C in oven. Melt blending of nanocomposites wascarried out by using micro-compounder at 270 °C processingtemperature, screw speed 100rpm and mixing time 5min. Thecontinuous strands obtained were pelletized and then followedby drying in the oven for injection molding. The micro-injectionmolding machine was used for the preparation of test specimenof PS/l-MWCNT and TPC/s-MWCNT nanocomposites. Cylindertemperature, mold temperature and pressure for injectionmolding were 250 °C, 100 °C and 640bar respectively. Theformulation and sample designation of the PS/l-MWCNT andTPC/s-MWCNT composites are given in Table 1. The schematicrepresentation of the nanocomposites fabrication is illustratedin Figure 1.

*where PS-polystyrene, TPC- toughened polycarbonate,l-CNT- long multiwalled carbon nanotube, s-CNT- smallmultiwalled carbon nanotube, Numerical value- MWCNTcontent.

Characterization of PS/MWCNT and TPC/MWCNTnanocomposites

PS and TPC nanocomposites were characterized bymorphological, electrical, EMI shielding thermal andspectroscopy study. Surface morphology of these nanocompositeswere inspected using scanning electron microscope (SEM ZeissEVO 50 at magnification of 30,000) and transmission electronmicroscope (TEM Zeiss 200kV). The cryofractured surfaceof composites were used for SEM imaging. The electricalconductivity (EC) of the nanocomposites at room temperaturewas measured by two point contact method using a Keithley 224programmable current source. Electromagnetic interferenceshielding of composites were recorded on Agilent E8362BVector Network Analyzer (VNA) in 8.2-12.4GHz frequency range(X-band).

Results and Discussion

Morphological characterization

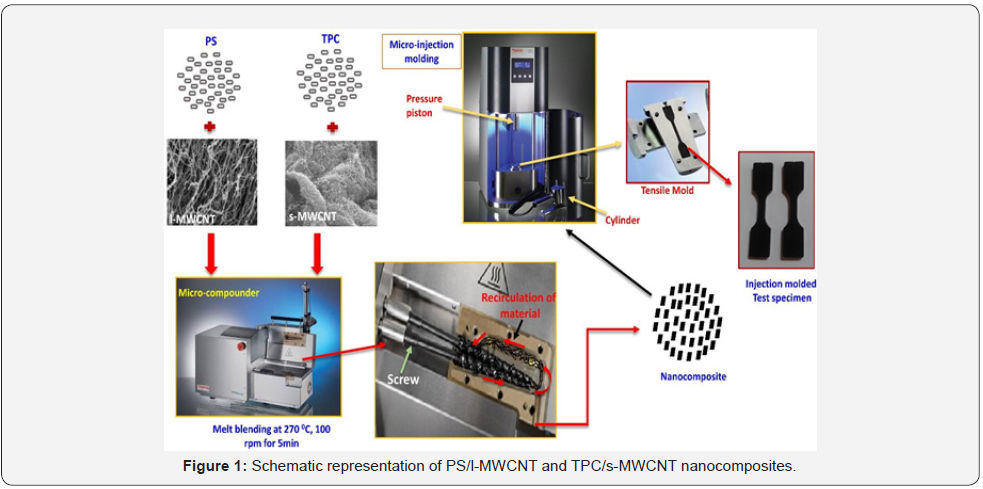

SEM images of l-MWCNTs and s-MWCNT based PS and TPUnanocomposites are presented in Figure 2a - 2h respectively.MWCNTs are homogenously dispersed in the matrix, evenat 10phr loading as observed from the images. Thus, meltblending using micro-compounder is an effective techniquefor homogenous dispersion of MWCNTs in matrix. From SEMimages, it is also observed that, at any specific MWCNT loading,the distribution density of s-MWCNT in TPC matrix is highercompared to l-MWCNTs in PS matrix. These s-MWCNTs havemore surface area in comparison to l-MWCNTs for interfacialinteractions with TPC matrix, which are necessary for goodmechanical strength and EMI shielding. On other side, l-MWCNTswith higher aspect ratio are expected to provide good stresstransfer properties, low percolation threshold and long-range charge transport in PS matrix. Therefore, depending on theaspect ratio of MWCNTs, their distribution and loading insidematrix, significant mechanical, electrical and EMI shieldingproperties are expected.

Electrical conductivity (EC)

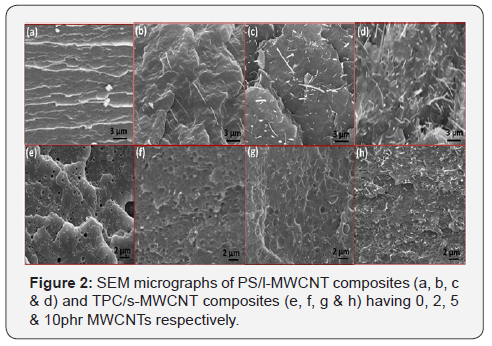

The EC of PS/l-MWCNT and TPC/s-MWCNT nanocompositeswith respect to MWCNT loading is presented in Figure 3. TheEC of nanocomposites based on l- and s-MWCNT increased withincreasing MWCNT loading and shows a drastic increase (~eight and seven orders of magnitude respectively) below 1phrMWCNT content, which show the formation of 3D conductingnetworks. Such a low percolation threshold value is due tothe uniform dispersion of MWCNTs in matrix. It is reported inliterature that percolation threshold is basically dependent onthe different factors like the aspect ratio, intrinsic conductivityand dispersion of the conductive nanofiller [25-27]. Therefore,the exact value of threshold of l- and s-MWCNTs, has beenprojected by plotting the EC as a function of the MWCNT loadingand performing data fitting using the scaling law [28-

where σ , σ 0 , ρ , ρ 0 and t represents the EC of thenanocomposites the intrinsic conductivity of the nanofiller,volume fraction of nanofiller, the volume fraction at thepercolation threshold and the critical exponent related to thesystem dimensionality respectively.

The linear regression data fitting (Figure 4 b & 4c) gives ρ0 =0.83phr & β = 1.54 for PS/l-MWCNT and ρ0 = 1.07 wt.% & β = 1.09 for TPC/s-MWCNT nanocomposites.Considering the good dispersion of both l- and s- MWCNTs, the lowpercolation threshold for l-MWCNTs can be attributed to its highaspect ratio as compared to s-MWCNTs. It can also be seen thatat any loading level, EC of PS/l-MWCNT nanocomposite is higherthan respective TPC/s-MWCNT nanocomposite. This can againbe attributed to the higher aspect ratio of l-MCWNTs responsiblefor long range charge transport in nanocomposites. As the EMIshielding is also related to the EC, the observed EC trend ofnanocomposites recommend that, at comparative loading, EMIshielding effectiveness of PS/l-MWCNT nanocomposites shouldbe higher than TPC/s-MWCNT nanocomposites.

Electromagnetic interference shielding (EMI SE) of nanocomposites

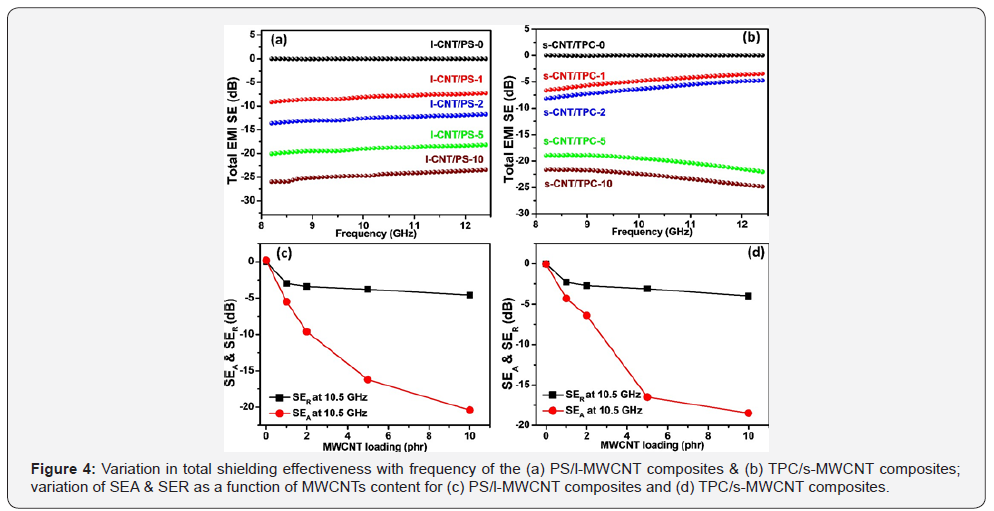

The EMI SE is the capacity of a material to attenuate incidentelectromagnetic waves. The EMI shielding is a direct result ofthe absorption of the wave as it passes through the shield’sthickness, the reflection of the wave from the front face ofthe shield and multiple reflections of the waves at variousinterfaces. The presence of charge carriers in material helpsin electromagnetic wave reflection via reflection mechanismelectromagnetic wave penetrate through the material andget attenuated via the absorption. Absorption loss is moreimportant for the magnetic field of electromagnetic wave thanthe electric field. Therefore, the electric field of electromagneticwave is mostly reflected at the interface. The total SE of amaterial can be expressed in logarithmic power ratio as [32]

Where SEA, SER and SEM are the SE due to absorption,reflection and multiple reflections respectively and Pi is thepower of incident wave and Pt is transmitted EM wave.

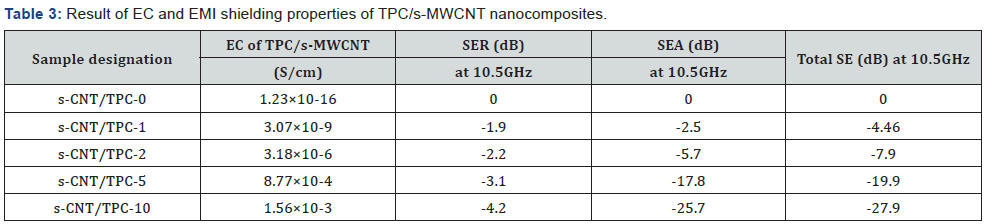

Figure 4a & 4b shows the total SE of PS/l-MWCNT and TPC/s-MWCNT nanocomposites respectively. It can be observed thatneat matrix (PS and TPC) sample gives negligible attenuation.However, incorporation of MWCNTs causes enhancement inSE for both PS/l-MWCNT and TPC/s-MWCNT nanocompositesobtaining SE value of - 21dB and - 27dB at 10phr loadingof MWCNT, respectively as given in Table 2 & 3. This can beascribed to the formation of conducting networks throughoutthe insulating PS and TPC matrix. The EMI shielding results alsoshown that at lower loading (up to 2phr MWCNT loading), SE ofPS/l-MWCNT nanocomposites is higher compared to s-MWCNTbased nanocomposites, but at higher loadings, s-MWCNT basedcomposites show higher EMI SE. Accordingly, PS/l-MWCNT-1and TPC/s-MWCNT-2 show approximate similar shieldingeffectiveness (~-7.8db). These results indicate the effectivenessof l-MWCNTs at lower loading and s-MWCNTs at higher loading.

The total SE have two components i.e. reflection andabsorption (SER and SEA). Both SER and SEA increases withMWCNT loading can be observed from Figure 4c & 4d. The SEAincreases at much faster rate as compare to SER in both the caseswith increase in MWCNT loading. A brief investigation showsthat at any given loading l-MWCNTs filled nanocompositesshow superior SER value as compare to s-MWCNTs fillednanocomposites. However, absorption trend shown that below5phr loading of CNT, PS/l-MWCNT nanocomposites showsuperior SEA values whereas at higher loadings, SEA of TPC/s MWCNT nanocomposites dominate. This can be attributed to thefact that at lower loadings, the interfacial polarization effects arenot too dominant, and conductivity shows the important role.Consequently, the TPC/s-MWCNT nanocomposites with a lowerconductivity compare to PS/l-MWCNT nanocomposites showlesser attenuation. However, at higher loadings, better inputimpedance matching in case of TPC/s-MWCNT nanocompositesallows more incident waves to enter inside the shield that can beeffectively dominated by absorption mechanism.

Conclusion

PS/MWCNT and TPC/MWCNT nanocomposites having up to10phr loading of different aspect ratio MWCNTs (i.e. long andshort MWCNTs respectively) have been prepared by melt mixingmethod. These nanocomposites show improved electricalconductivity and low electrical percolation threshold (i.e. 0.83and 0.91phr for PS/l-MWCNT and TPC/s-MWCNT compositesrespectively) which is the sign of uniform dispersion ofMWCNTs in the matrix. Further, the good electrical conductivity,processing induced morphology and difference in aspect ratioare responsible for observed maximum attenuation of -21dB and-27dB for PS/l- MWCNT and TPC/s-MWCNT nanocompositesrespectively. It was also detected that PS/l-MWCNTnanocomposites show better SE at lower loading (up to 5phr)whereas TPC/s-MWCNT nanocomposites give better SE at higherloading. The aspect ratio of MWCNTs have been interconnectedwith the observed trends of electrical conductivity and EMI SE.These nanocomposites with good electrical conductivity alongwith high EMI shielding are considered as potential aspirant formaking commercially feasible EMI shields.

References

- Cao MS, Yang J, Song WL, Zhang DQ, Wen B, et al. (2012) Ferroferricoxide/multiwalled carbon nanotube vs polyaniline/ferroferric oxide/multiwalled carbon nanotube multiheterostructures for highlyeffective microwave absorption. ACS Appl Mater Interfaces 4(12):6949-6956.

- Verma P, Saini P, Malik RS, Choudhary V (2015) Excellentelectromagnetic interference shielding and mechanical properties ofhigh loading carbon-nanotubes/polymer composites designed usingmelt recirculation equipped twin-screw extruder. Carbon 89: 308-317.

- Özdemir F, Kargi A (2011) Electromagnetic Waves and Human Health.In Electromagnetic Waves 474-490.

- Zamanian A, Hardiman C (2005) Electromagnetic Radiation andHuman Health: A Review of Sources and Effects. High FrequencyElectronics 4:16.

- Hardell L, Sage C (2008) Biological effects from electromagnetic fieldexposure and public exposure standards. Biomed Pharmacother62(2): 104-109.

- Chung DD (2001) Electromagnetic interference shielding effectivenessof carbon materials. Carbon 39(2): 279-285.

- Chung DD (2000) Materials for Electromagnetic Interference Shielding.J Mater Eng Perform 9(3): 350-354.

- Al-Saleh MH, Saadeh WH, Sundararaj U (2013) EMI shieldingeffectiveness of carbon based nanostructured polymeric materials: Acomparative study. Carbon 60: 146-156.

- Chung DDL (2012) Carbon materials for structural self-sensing,electromagnetic shielding and thermal interfacing. Carbon 50(9):3342-3353.

- Andrews R, Weisenberger MC (2004) Carbon nanotube polymercomposites. Curr Opin Solid State Mater Sci 8(1): 31-37.

- Bauhofer W, Kovacs JZ (2009) A review and analysis of electricalpercolation in carbon nanotube polymer composites. Compos SciTechnol 69910): 1486-1498.

- Spitalsky Z, Tasis D, Papagelis K, Galiotis C (2010) Carbon nanotubepolymercomposites: Chemistry, processing, mechanical and electricalproperties. Prog Polym Sci 35(3): 357-401.

- Thomassin JM, Jérôme C, Pardoen T, Bailly C, Huynen I, et al. (2013)Polymer/carbon based composites as electromagnetic interference(EMI) shielding materials. Mater Sci Eng R 74(7): 211-232.

- Kim HM, Kim K, Lee CY, Joo J, Cho SJ, et al. (2004) Electrical conductivityand electromagnetic interference shielding of multiwalled carbonnanotube composites containing Fe catalyst. Appl Phys Lett 84(4):589-591.

- Li N, Huang Y, Du F, He X, Lin X, et al. (2006) ElectromagneticInterference (EMI) Shielding of Single-Walled Carbon Nanotube EpoxyComposites. Nano Lett 6(6): 1141-1145.

- Verma P, Saini P, Choudhary V (2015) Designing of carbon nanotube/polymer composites using melt recirculation approach: Effect of aspectratio on mechanical, electrical and EMI shielding response. Mater Des88: 269-277.

- Gupta A, Choudhary V (2011) Electromagnetic interference shieldingbehavior of poly(trimethylene terephthalate)/multi-walled carbonnanotube composites. Compos Sci Technol 71(13): 1563-1568.

- Bai JB, Allaoui A (2003) Effect of the length and the aggregate sizeof MWNTs on the improvement efficiency of the mechanical andelectrical properties of nanocomposites-experimental investigation.Compos Part A Appl Sci Manuf 34(18): 689-694.

- Singh BP, Saini K, Choudhary V, Teotia S, Pande S, et al. (2013) Effect oflength of carbon nanotubes on electromagnetic interference shieldingand mechanical properties of their reinforced epoxy composites. JNanoparticle Res 16: 2161-2169.

- Huang Y, Li N, Ma Y, Du F, Li F, et al. (2007) The influence of singlewalledcarbon nanotube structure on the electromagnetic interferenceshielding efficiency of its epoxy composites. Carbon 45(8): 1614-1621.

- Guo J, Liu Y, Prada-Silvy R, Tan Y, Azad S, et al. (2014) Aspect ratioeffects of multi-walled carbon nanotubes on electrical, mechanical,and thermal properties of polycarbonate/MWCNT composites. J PolymSci Part B Polym Phys 52(1): 73-83.

- Bagotia N, Singh BP, Choudhary V, Sharma DK (2015) Excellentimpact strength of ethylene-methyl acrylate copolymer toughenedpolycarbonate. RSC Adv 5: 87589-87597.

- Bagotia N, Choudhary V, Sharma DK (2017) Studies on toughenedpolycarbonate/multiwalled carbon nanotubes nanocomposites.Compos Part B Eng 124(1): 101-110.

- Bagotia N, Mohite H, Tanaliya N, Sharma DK (2017) A comparativestudy of electrical, EMI shielding and thermal properties of grapheneand multiwalled carbon nanotube filled polystyrene nanocomposites.Polym Compos 39(S2): E1041-E1051.

- Al-Ghamdi AA, El-Tantawy F (2010) New electromagnetic waveshielding effectiveness at microwave frequency of polyvinyl chloridereinforced graphite/copper nanoparticles. Compos Part A Appl SciManuf 41(11): 1693-1701.

- El-Tantawy F, Al-Ghamdi AA, Aal NA (2010) New PTCR thermistors,switching current, and electromagnetic shielding effectiveness from nanosized vanadium sesquioxides ceramic reinforced epoxy resinnanocomposites. J Appl Polym Sci 115(2): 817-825.

- Saini P, Choudhary V, Sood KN, Dhawan SK (2009) Electromagneticinterference shielding behavior of polyaniline/graphite compositesprepared byin situemulsion pathway. J Appl Polym Sci 113(5): 3146-3155.

- Maiti S, Suin S, Shrivastava NK, Khatua BB (2013) Low PercolationThreshold in Polycarbonate/Multiwalled Carbon NanotubesNanocomposites Through Melt Blending with Poly(butyleneterephthalate). J Appl Polym Sci 130(1): 543-553.

- Maiti S, Suin S, Shrivastava NK, Khatua BB (2013) Low percolationthreshold in melt-blended PC/MWCNT nanocomposites in thepresence of styrene acrylonitrile (SAN) copolymer: Preparation andcharacterizations. Synth Met 165: 40-50.

- Mondal S, Nayak L, Rahaman M, Aldalbahi A, Chaki TK, et al.(2017) An effective strategy to enhance mechanical, electrical, andelectromagnetic shielding effectiveness of chlorinated polyethylenecarbonnanofiber nanocomposites. Compos Part B Eng 109: 155-169.

- Arjmand M, Apperley T, Okoniewski M, Sundarara U (2012) Comparativestudy of electromagnetic interference shielding properties of injectionmolded versus compression molded multi-walled carbon nanotube/polystyrene composites. Carbon 50(14): 5126-5134.

- Das NC, Khastgira D, Chakia TK, Chakraborty A (2000) Electromagneticinterference shielding effectiveness of carbon black and carbon fibrefilled EVA and NR based composites. Compos Part A Appl Sci Manuf31(10): 1069-1081.